Open-type acetylene generator automatic feeding system

An acetylene generator and automatic feeding technology, applied in the acetylene generator, the parts of the acetylene gas generator, the petroleum industry, etc., can solve the problems of high labor consumption, large loss of calcium carbide, trouble, etc., and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

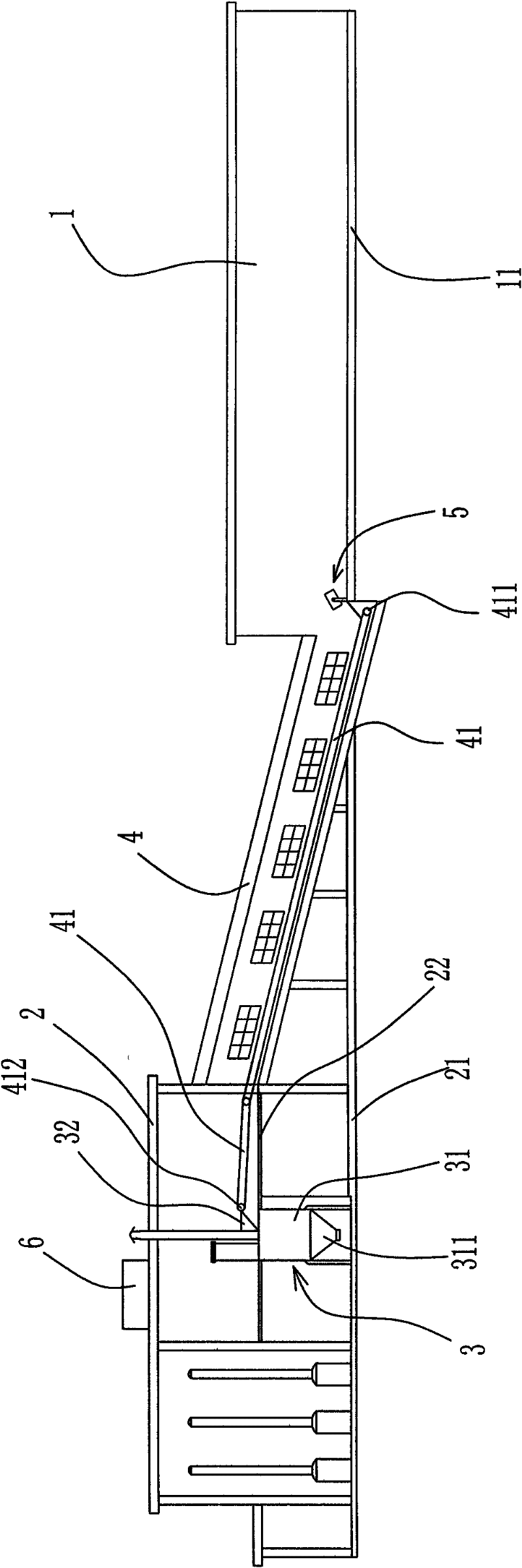

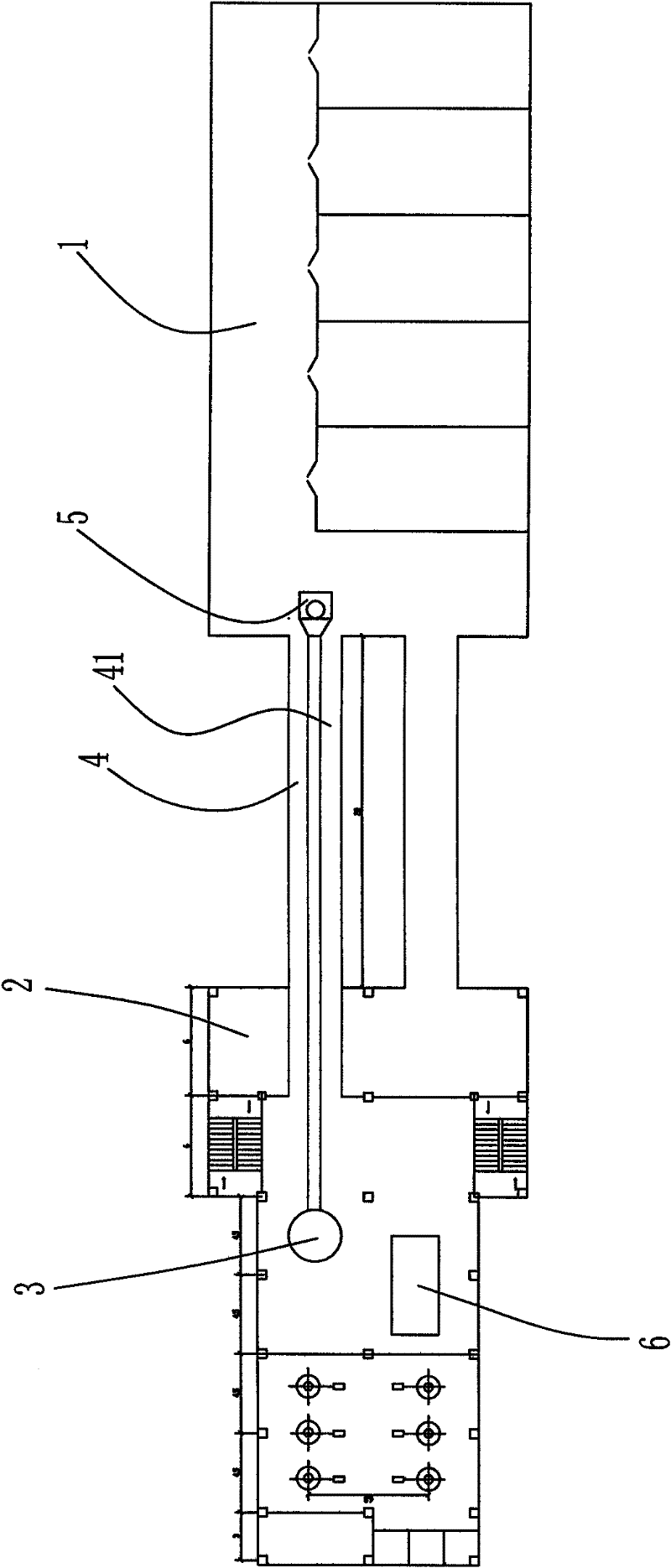

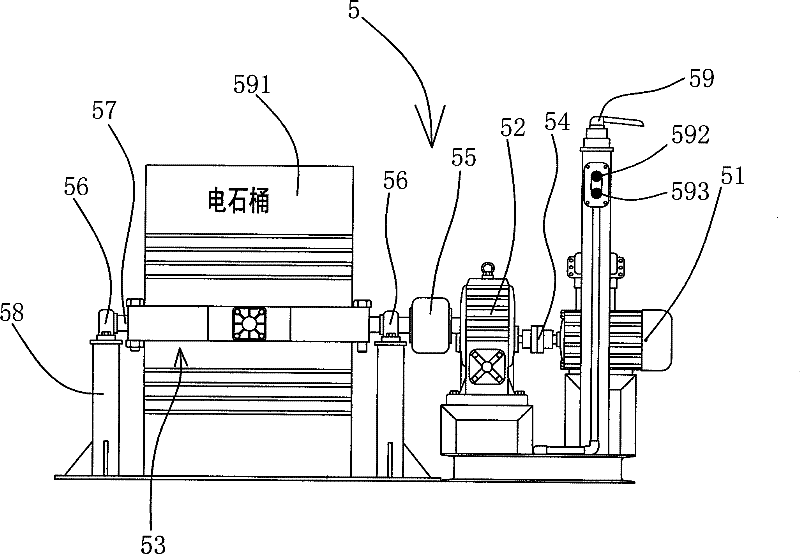

[0029] See figure 1 with figure 2 , figure 1 with figure 2 Disclosed is an open-type acetylene generator automatic feeding system, including calcium carbide storage 1 and an open-type acetylene generation workshop 2, the distance between the calcium carbide storage 1 and the open-type acetylene generation workshop 2 is at least 20 meters, in the An open acetylene generator 3 is arranged in the open acetylene generation workshop 2, and the reaction tank body 31 of the open acetylene generator 3 is arranged on the first floor 21 and the second floor of the open acetylene generation workshop 2. Between the floors 22, the feed hopper 32 of the open acetylene generator 3 is located above the second floor 22, between the first floor 11 of the calcium carbide storehouse 1 and the open acetylene Between the floors 22 of the second floor of the workshop 2, there is an oblique calcium carbide conveyor belt corridor 4 connecting the two, and a belt conveyor 41 is arranged in the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com