Automatic operation device of upper drill floor and lower drill floor of drill rod

A technology of operating devices and drill pipes, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high requirements for operators, low production efficiency, complicated operation process, etc., and achieve low mechanization and automation, structural design, etc. Reasonable, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

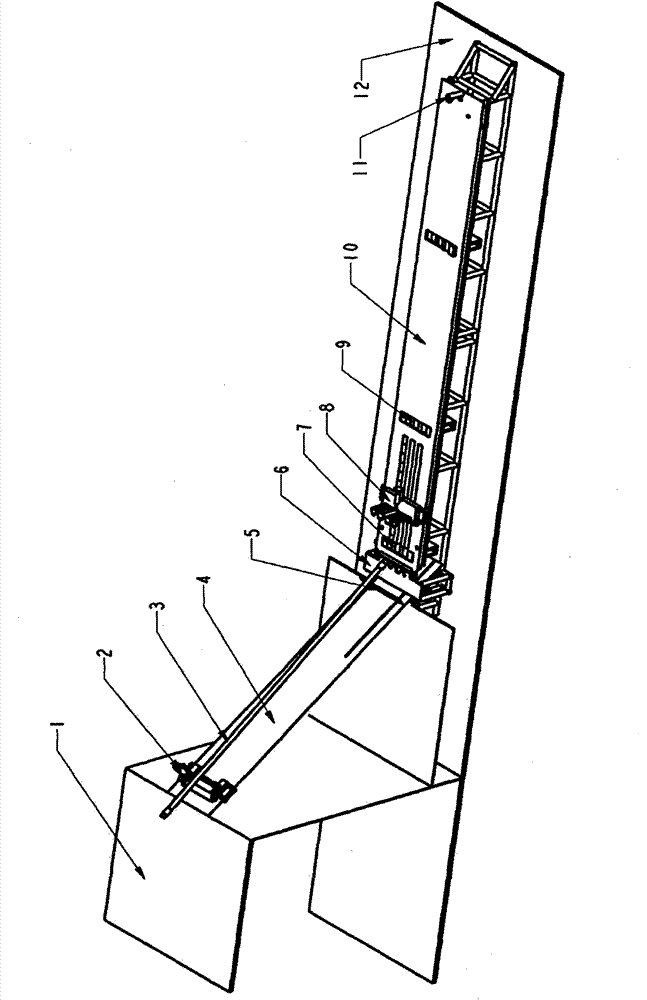

[0013] refer to figure 1 , the automatic operation device for drill pipes going up and down the drill floor in this embodiment includes: the ramp 4 is overlapped on the drilling platform 1 obliquely above, and the bottom is fixed on the support frame on the ground 12 together with the catwalk 10 . On the ramp 4, there is a ramp car 2 which slides and cooperates with the ramp, and a ramp pushing mechanism 5 is provided at the lower end of the ramp. The front end of the catwalk 10 (that is, the butt joint with the ramp) is provided with an overturning mechanism 6, and on the catwalk backward along the overturning mechanism 6, there are a lifting mechanism 7, a catwalk trolley 8, two groups of spaced apart drilling rod pushing mechanisms 9 and Catwalk car off-proof block 11. The drilling rod 3 is located on the turning mechanism 6 and the ramp car 2 .

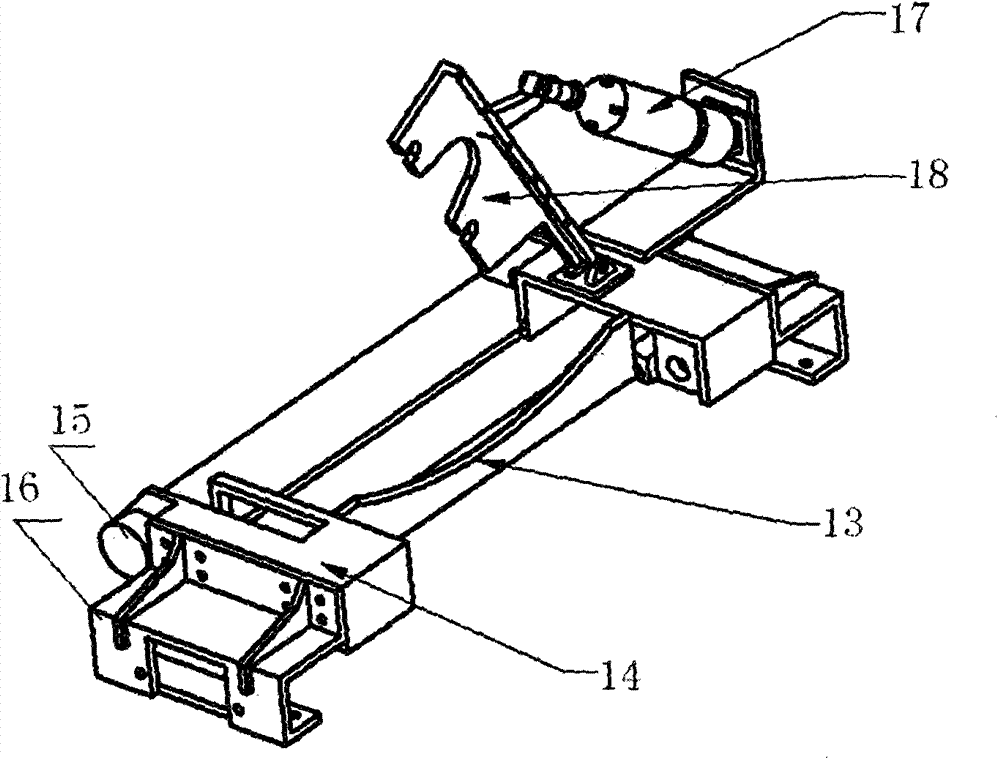

[0014] Refer to attached figure 2 , the main body 14 of the ramp car 2 is connected to the lower deck 13 of the drill rod, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com