Closed automatic slag discharge device for boiling chlorination furnace

A fluidized chlorination furnace and automatic slag removal technology, applied in fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of low reaction efficiency, low utilization rate of chlorine gas, and chlorine gas polluted environment, etc., to solve serious environmental pollution, Improve the utilization rate of chlorine gas and the effect of complete reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

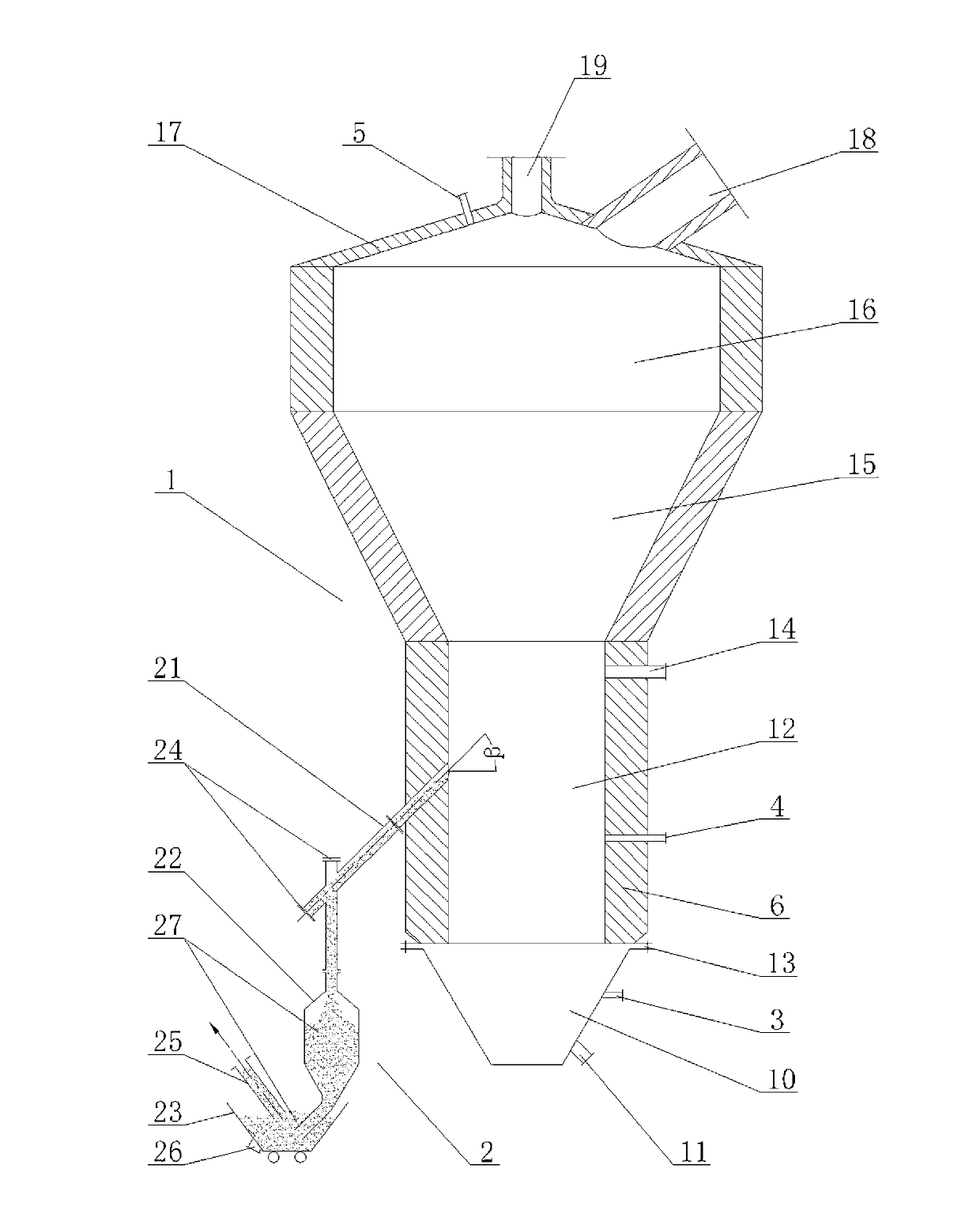

[0015] Such as figure 2 As shown, the closed automatic slagging device of the fluidized chlorination furnace of the present invention comprises a furnace body 1 and a slagging device 2 connected with the furnace body 1, and the slagging device includes a slagging pipe 21, a slag tank 22 and The slag storage hopper 23, wherein the slag discharge pipe 21 is installed on the boiling section 12 of the furnace body inclined downward, and the input port of the slag discharge pipe 21 is connected with the inner cavity of the furnace body, and the output port is connected with the input port of the slag tank 22 The output port of the slag tank 22 is located in the cavity of the slag storage hopper 23. In order to prevent chlorine gas from leaking out during the slag discharge process, the slag discharge device 2 uses a certain amount of slag 27 retained in the slag tank 22 to form the first The first material seal, and the slag 27 automatically discharged into the slag storage hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com