Polyhedral energy-accumulating metal blasting fuse and using method thereof

A technology of detonating cord and metal, which is applied in the production of detonating equipment and in the field of detonation, and can solve the problems that have not yet been reported on metal detonating cord.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

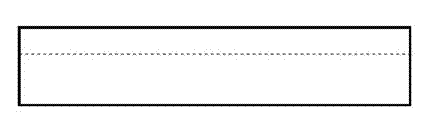

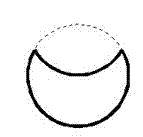

[0022] see figure 1 , The detonating cord is cylindrical, the outer diameter is 3.0mm, the metal outer layer wrapped on the surface is aluminum, the tube wall thickness is 0.25mm, the drug core charge is RDX, and the drug core linear density is 3.6g / m. On the outer surface of the aluminum tube, there is a through arc groove, the diameter of the arc groove is the same as that of the detonating cord, and the depth of the groove is 1.5mm. figure 2 .

[0023] image 3 , Figure 4 expressed the two figure 1 The metal detonating cord in the method is connected in a side-to-side "1-to-1" detonation transmission method. Wherein, the detonating cord to be detonated is placed in the detonating cord groove which plays the role of detonating. Since the diameter of the two detonating cords is the same as the diameter of the arc groove, the two can be in close contact, and the length of the overlapping part is 3cm, and the detonation can be realized after being bound firmly with adhes...

Embodiment 2

[0026] see Figure 5 , The detonating cord is cylindrical, with an outer diameter of 3.0mm, the metal outer layer wrapped on the surface is aluminum, the tube wall thickness is 0.25mm, the core charge is RDX, and the charge linear density is 3.6g / m. There is a penetrating angular groove on the outer circular surface of the energy-shaping metal detonating cord aluminum tube, the two corners are equal, the apex angle is 110 degrees, and the apex reaches the center of the outer circular surface of the energy-shaping metal detonating cord aluminum tube The distance is 1 / 2 the radius of the metal detonating cord.

[0027] Figure 6 is to combine two Figure 5 Schematic diagram of the parallel method of detonating the metal detonating cord in the sideways "1 pass 1" detonation. When connecting sideways in parallel, place the detonating cord to be detonated in the groove of the detonating cord that plays the role of detonating, so that the two are as close as possible, the length ...

Embodiment 3

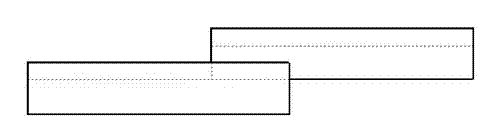

[0030] Figure 7 Among them, the detonating cord 1 is an energy-shaping metal detonating cord with one groove, and the detonating cord 2 to be detonated is an ordinary circular metal detonating cord. The outer diameter of 1 is 4.0mm, the metal outer layer is aluminum, and the wall thickness is 0.3mm. There is a groove with a length of 10cm on the surface of the aluminum tube. arc on . 2 is the ordinary metal detonating cord that is circular in shape, and the outer diameter is 4.0mm. The core charge of 1 and 2 is RDX, and the charge linear density is 6.5g / m.

[0031] Figure 7 It is a schematic diagram when the above two metal detonating cords are connected sideways in parallel. Ordinary metal detonating cord 2 is placed in the groove of detonating detonating cord 1, so that the two are as close as possible, and the length of the overlapping part is 8cm. Use adhesive tape to bind the overlapping parts firmly to realize parallel explosion transmission.

[0032] After the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com