High-frequency step-up transformer and progressive high-frequency step-up rectifying transformer

A step-up rectifier and transformer technology, which is applied in the fields of high-frequency step-up transformers and high-frequency step-up rectifier transformers, can solve the problems of reduced coupling efficiency of primary and secondary windings, insufficient maintenance of forward input excitation coupling, and reduced working efficiency of transformers. Transformer output efficiency, avoiding input return loss, maintaining reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

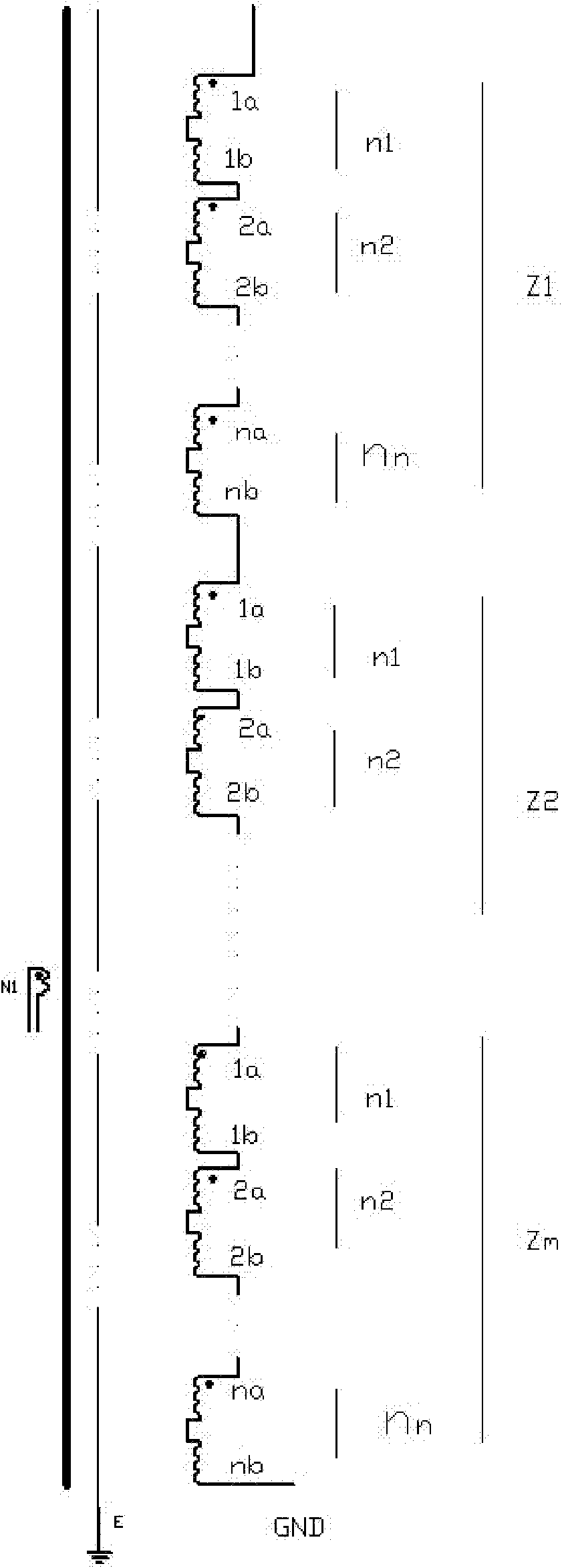

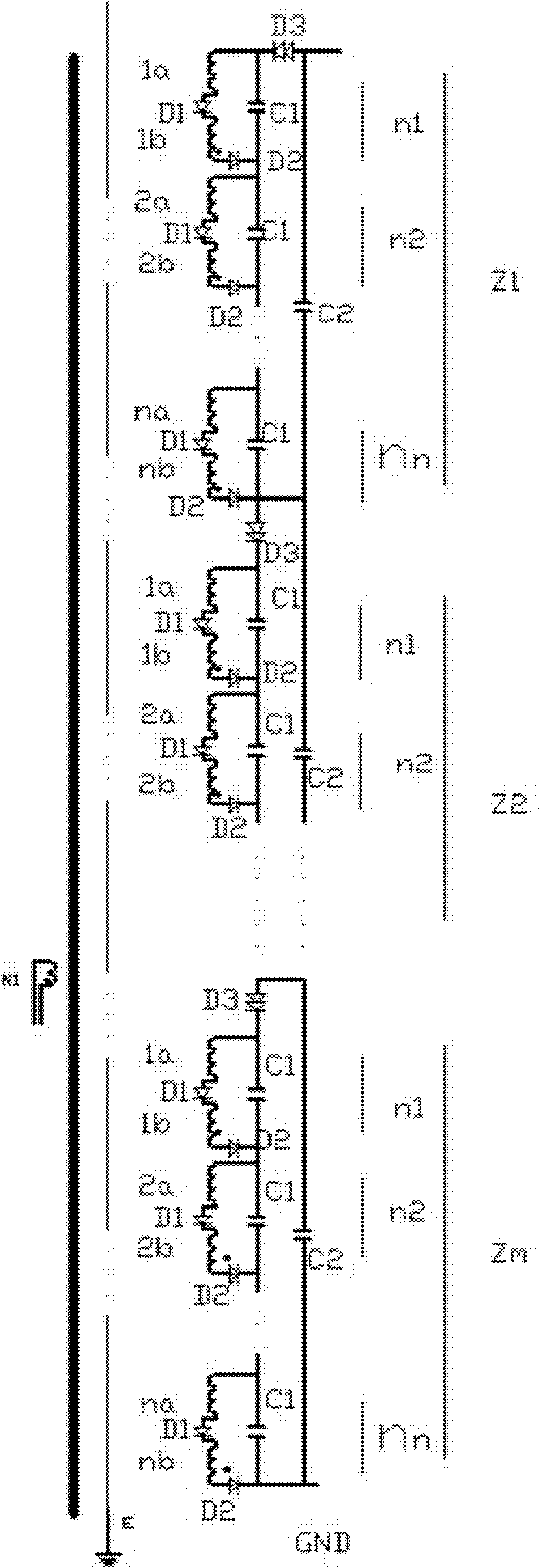

[0020] The high-frequency step-up transformer disclosed in the patent application of the present invention, such as figure 1 and Figure 9 , Figure 10 The structure shown in which the corresponding diodes and capacitors are connected is omitted, the primary winding N1 and the secondary winding N2 have the same end with the same name, the inner and outer layers are radially overlapped on the iron core 50 through the insulating shielding layer 52, and the secondary winding N2 includes: A number of winding segments that are insulated in the same direction as the primary winding and in the same direction as the helix, and are insulated sequentially along the axis of the iron core n .

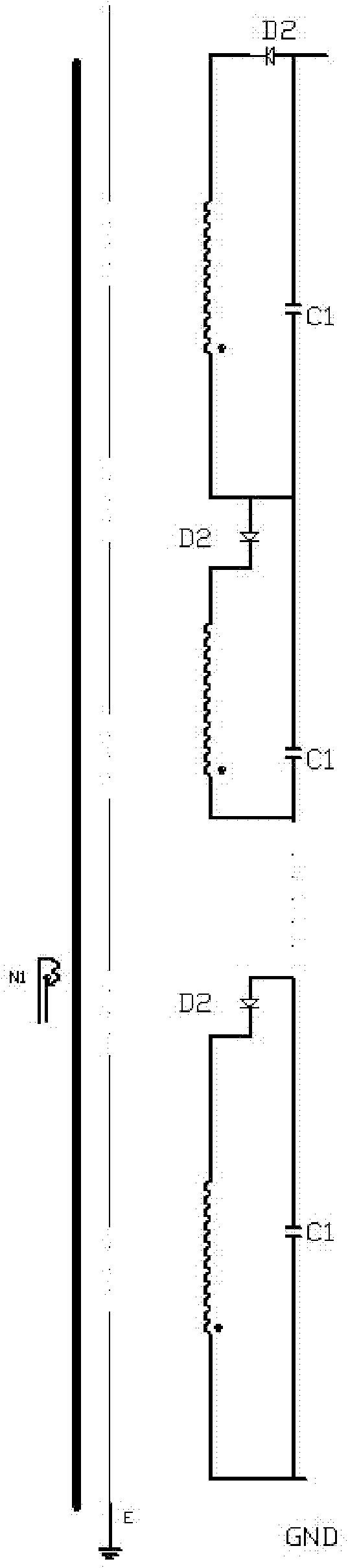

[0021] On the basis of the above-mentioned high-frequency step-up transformer, the present invention also provides a progressive high-frequency step-up rectifier transformer, such as figure 2 , image 3 , Figure 4 , Figure 5 as well as Figure 9 and Figure 10 As shown, it includes an ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com