Hydraulic Transformer Using Combined Valve Plate and Its Hydraulic Circuit

A hydraulic transformer, valve plate technology, applied in the direction of fluid pressure converter, fluid pressure actuating device, servo motor, etc., can solve problems such as no solution, vibration and noise valve plate, interface problems, etc., to improve displacement, The effect of reducing noise and cavitation, avoiding pressure surges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

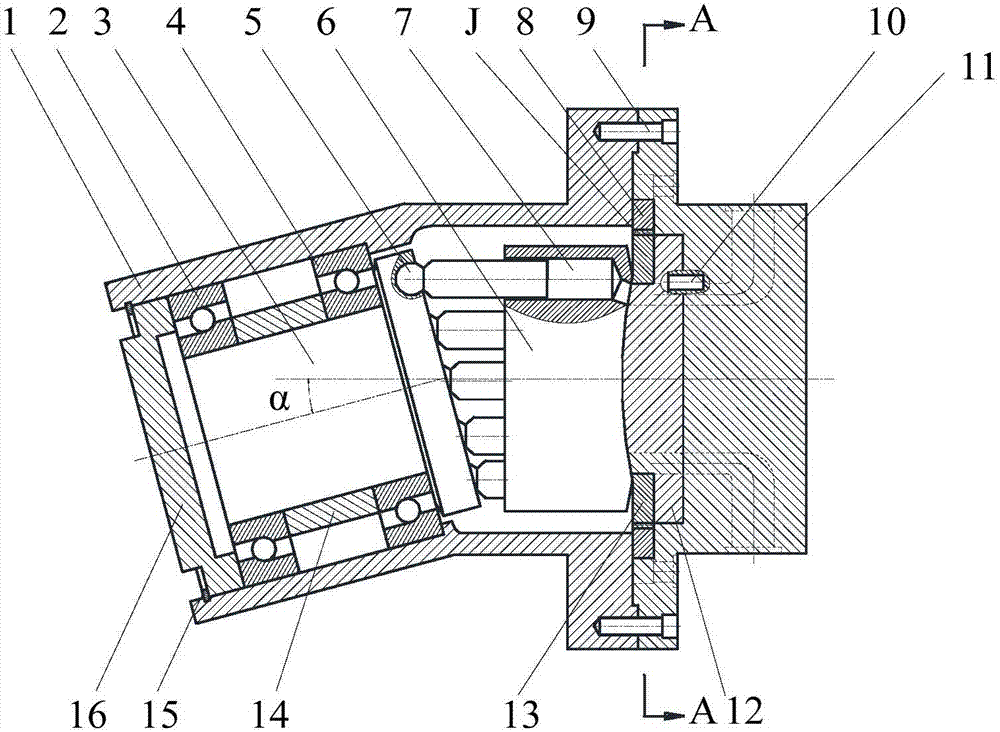

[0029] Such as figure 1 As shown, the front end cover 16, the front housing 1, and the rear housing 11 constitute a closed cavity of the inclined axis hydraulic transformer; the front end cover 16 has no opening hole, and the rotating shaft 3 is inside the closed cavity; the rotating shaft 3 passes The first bearing 2 and the second bearing 4 are installed in the central cavity of the front housing 1, the angle between the axis of the rotating shaft 3 and the axis of the plunger cylinder 6 is α=20°, the rotating shaft 3 and the plunger cylinder 6 rotate simultaneously During the process, the plunger 5 telescopically moves in the plunger cavity 7, and the plunger cavity realizes oil absorption and oil discharge;

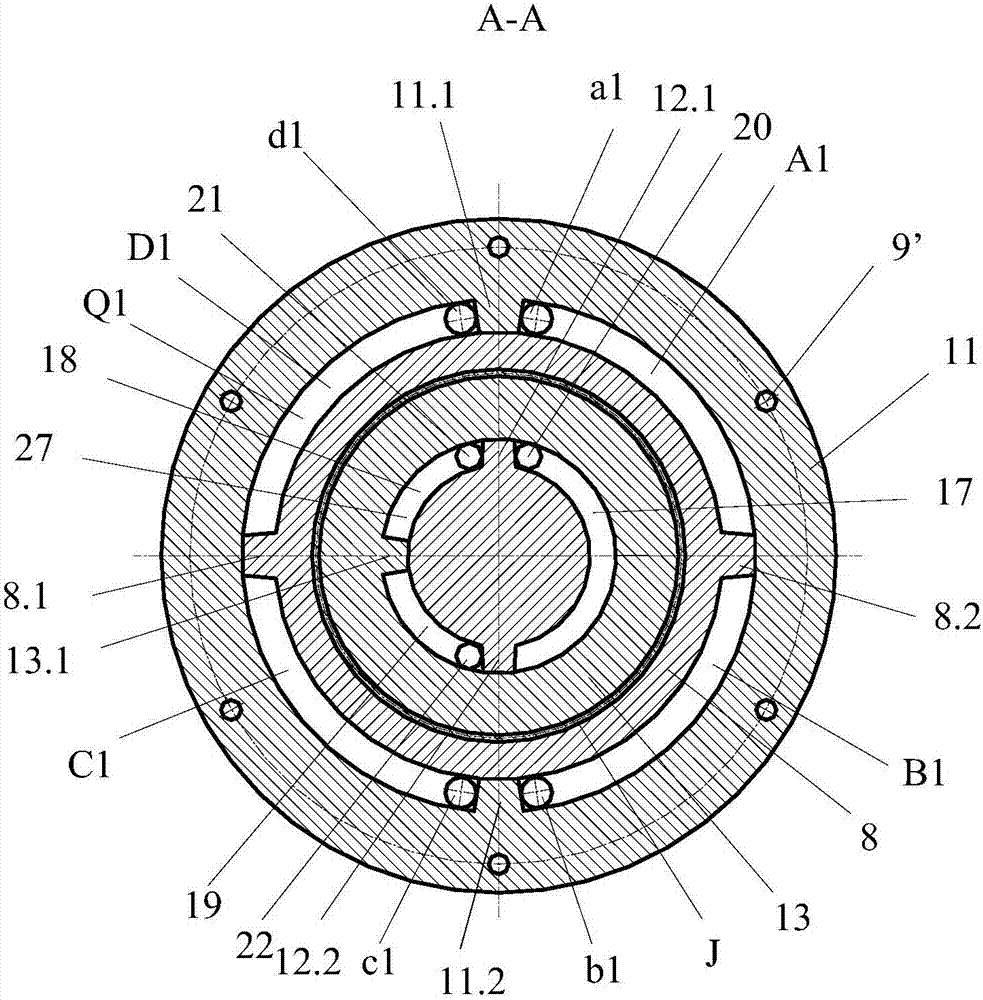

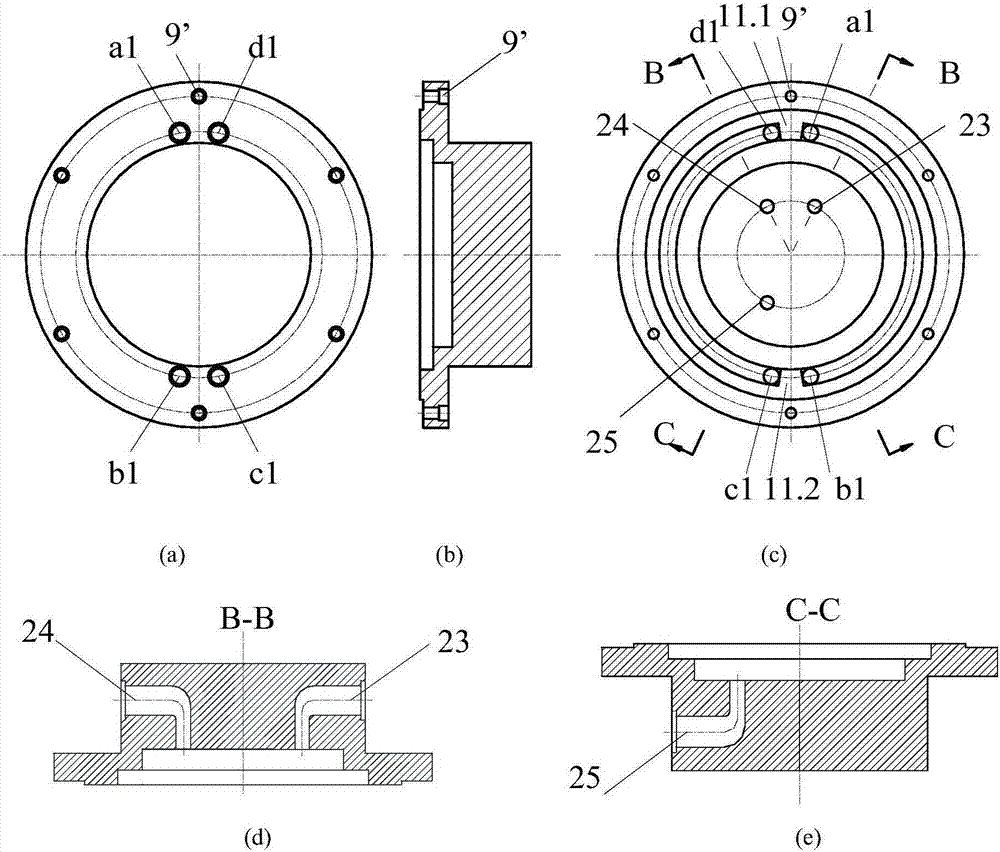

[0030] Such as figure 1 , 2 , 5 and 6, the inner plate 12 and the outer plate 13 together form a valve plate, which replaces the monolithic valve pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com