Semi-automatic intermittent kelp seedling planting machine

An intermittent, planting machine technology, applied in plant cultivation, seaweed cultivation, botanical equipment and methods, etc., can solve problems such as low efficiency, lack of related machinery, waste of manpower and material resources, etc., to increase planting area, simple operation, lightening The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

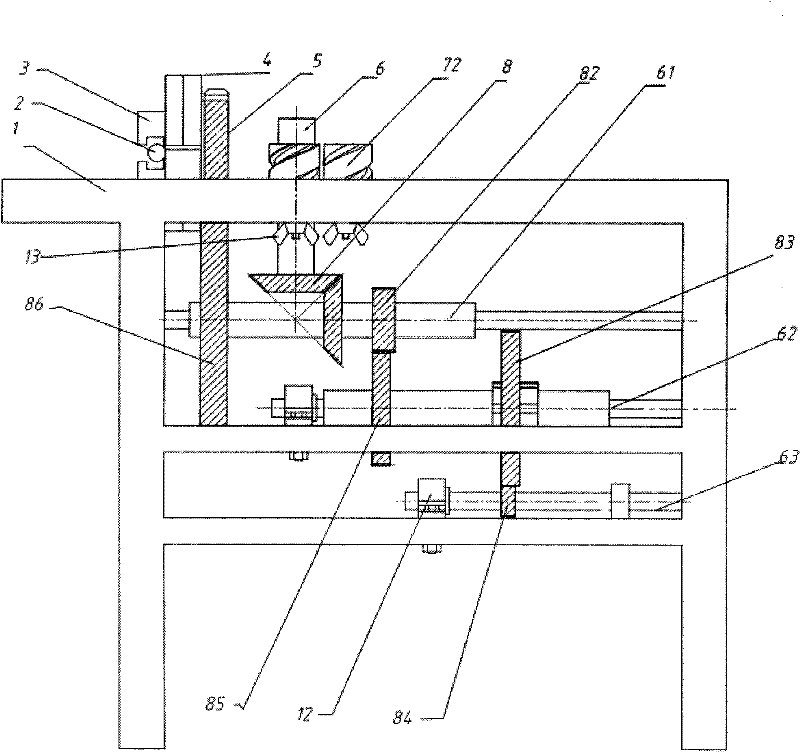

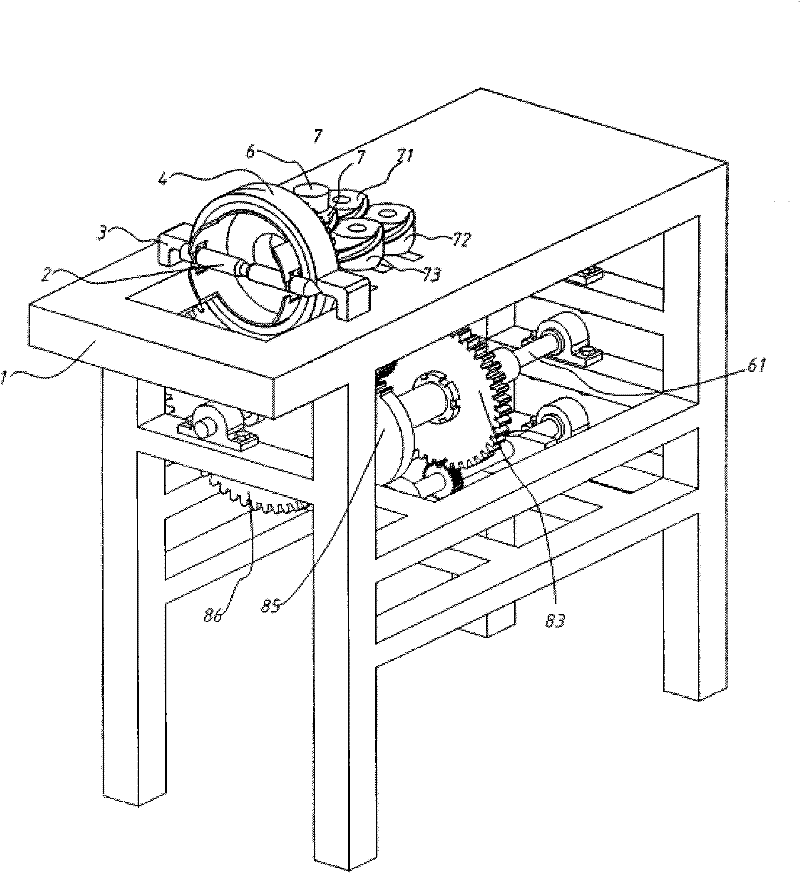

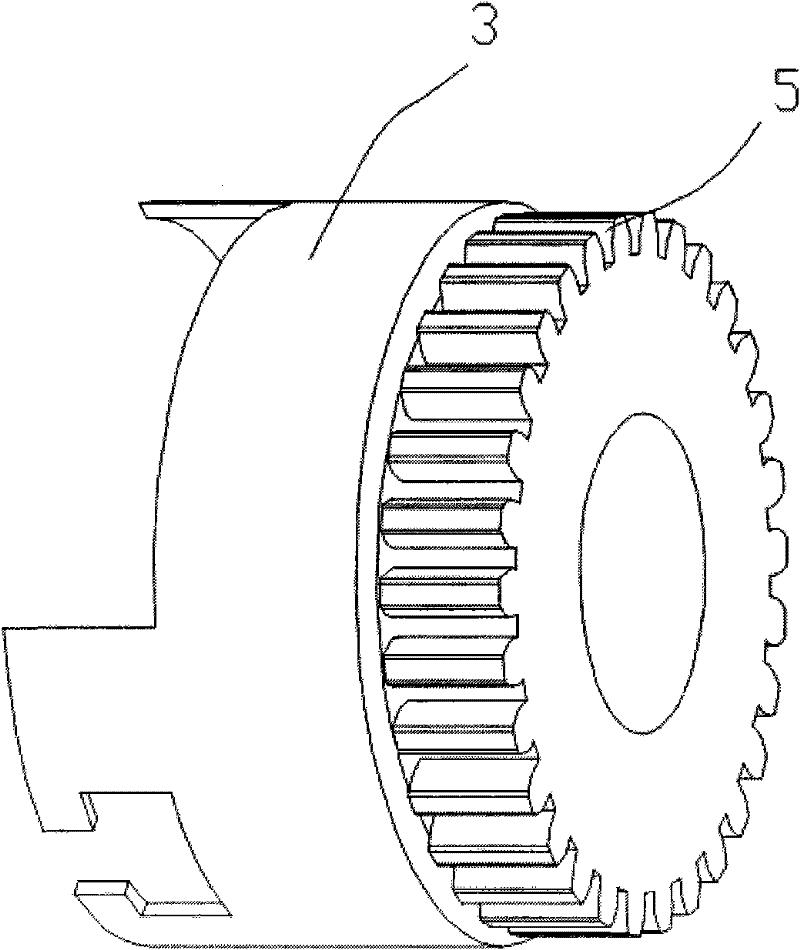

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 , a semi-automatic intermittent kelp seedling planter, comprising a frame 1, a twisting rope mechanism, a rope feeding mechanism and a driving device, a pin rod 2 and a supporting sleeve 4 that are arranged at one end of the pin cylinder 3 and rotate tangentially with the pin cylinder 3 A twisting rope mechanism is formed. The two shoulders of the supporting sleeve 4 in the twisting rope mechanism are provided with brackets, and the brackets are suspended and fixed in the square holes of the working panel to keep the central axis of the pin cylinder 3 at one to two rope positions above the working panel. One end of the pin barrel 3 is radially provided with a pair of slots, the slots are either a "convex" groove or an "L" shaped groove. To connect, pass one end of the kelp seedling rope through the pin cylinder 3, twist the seedling rope manually to create a gap and then insert the pin rod 2, the pin rod 2 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com