Composite gel and cereal suspension beverage and preparation methods thereof

A technology of composite gel and grain, which is applied in the fields of food science, food ingredients as gelling agents, food ingredients as taste improvers, etc. Rich variety, improving water retention, and preventing and controlling obesity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: preparation of curdlan micelle

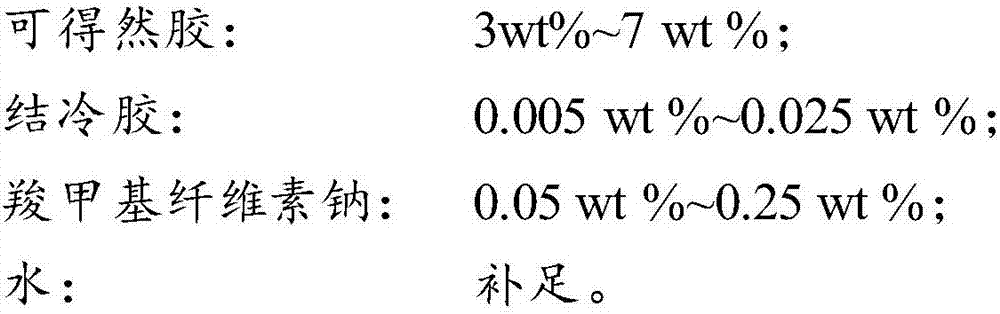

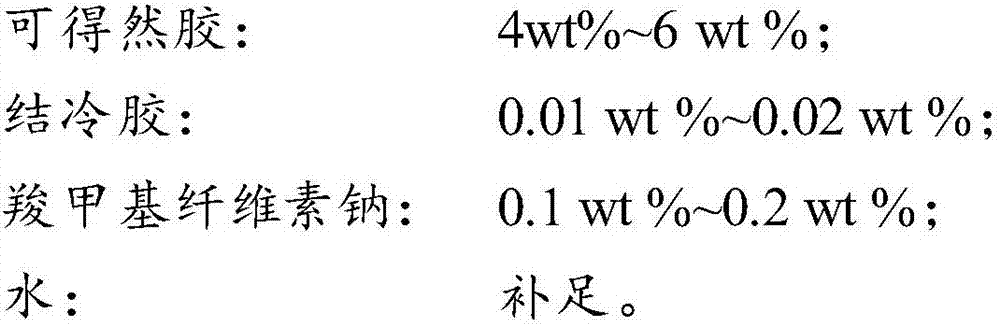

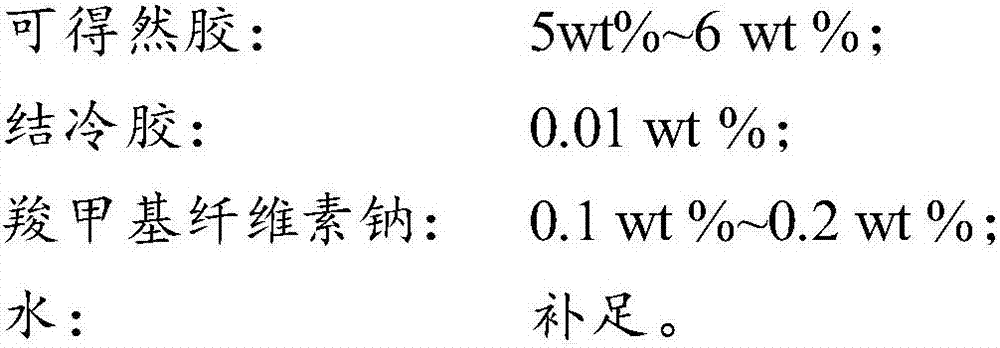

[0055] The raw material composition of curdlan gum granules is: curdlan gum 6%, gellan gum 0.01%, carboxymethyl cellulose sodium 0.1%, and the balance is water.

[0056] Its production process is:

[0057] After fully premixing gellan gum and sodium carboxymethyl cellulose, put it into 200mL hot water at 75°C and stir; add 700mL RO water (purified water) at 20°C to the colloid solution, and slowly add curdlan gum powder under the condition of 900rpm stirring, Stir for 10 minutes; dilute to 1kg with RO water; homogenize the conditioning solution twice under the homogeneous condition of 200 / 40bar; homogenize the material solution, heat it to 40°C in a water bath within 2 minutes, form a weak gel solution, and pack it in an iron can and seal it ; The iron can sample was sterilized at 121°C for 12 minutes; cooled, and the rubber block was cut into 3cm*3cm*3cm rubber particles.

Embodiment 2

[0058] Embodiment 2: Preparation of curdlan colloidal particles

[0059] The raw material composition of curdlan gum granules is: curdlan gum 5%, gellan gum 0.01%, carboxymethyl cellulose sodium 0.2%, and water as the balance.

[0060] Its production process is:

[0061] After fully premixing gellan gum and sodium carboxymethyl cellulose, put it into 200mL hot water at 75°C and stir; add 700mL RO water at 22°C to the colloid solution, slowly add curdlan gum powder under the stirring condition of 900rpm, and stir for 10min; The volume of RO water was fixed to 1kg; the conditioning solution was homogenized twice under the homogeneous condition of 200 / 40bar; the homogeneous material solution was heated to 42°C in a water bath within 2 minutes to form a weak gel solution and sealed in an iron can; the iron can sample After heating and sterilization at 120°C for 13 minutes; cooling, cut the rubber block into 3cm*3cm*3cm rubber particles.

Embodiment 3

[0062] Embodiment 3: preparation of curdlan micelle

[0063] The raw material composition of curdlan gum granules is: curdlan gum 6%, gellan gum 0.01%, carboxymethyl cellulose sodium 0.2%, and the balance is water.

[0064] Its production process is:

[0065] After fully premixing gellan gum and sodium carboxymethyl cellulose, put it into 200mL hot water at 75°C and stir; add 700mL RO water at 22°C to the colloid solution, slowly add curdlan gum powder under the stirring condition of 900rpm, and stir for 10min; The volume of RO water was fixed to 1kg; the conditioning solution was homogenized twice under the homogeneous condition of 200 / 40bar; the homogeneous material solution was heated to 45°C in a water bath within 2 minutes to form a weak gel solution and sealed in an iron can; the iron can sample After heating and sterilization at 120°C for 13 minutes; cooling, cut the rubber block into 3cm*3cm*3cm rubber particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com