Tank module for a motor vehicle

A technology for fuel tanks and automobiles, which is applied to the layout combined with the fuel supply of internal combustion engines, vehicle components, and methods of container discharge, etc., can solve problems such as large consumption and tedious post-processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

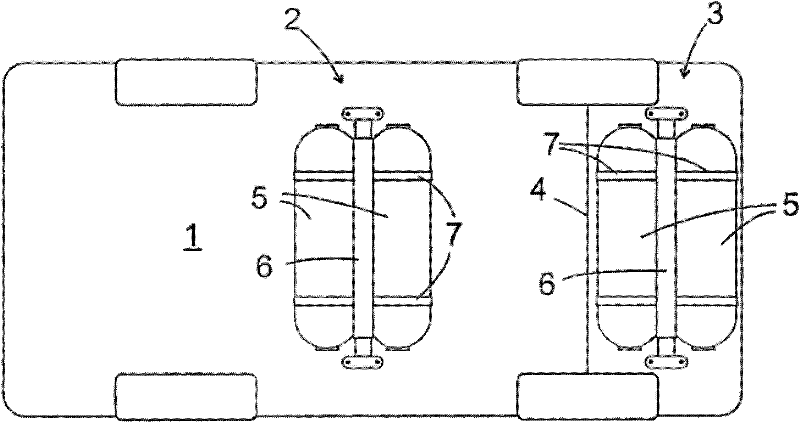

[0027] figure 1 A bottom view of a motor vehicle floor 1 on which two fuel tank modules 2 , 3 are mounted is schematically shown. Among the two fuel tank modules, the front fuel tank module 2 is roughly located under the front seats of the vehicle, and the rear fuel tank module 3 is located behind the rear axle 4 . Each fuel tank module 2 , 3 comprises two fuel containers 5 each having the shape of a cylinder with arched end sides. Such a fuel container 5 is especially suitable for containing high-pressure gas, however, in a hybrid vehicle, one or more fuel containers 5 may be provided for containing normally liquid fuels, such as gasoline or diesel fuel, alcohol, etc.

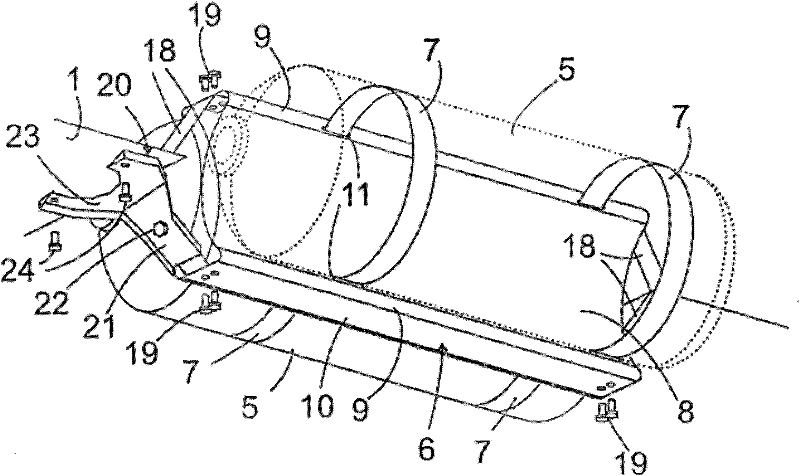

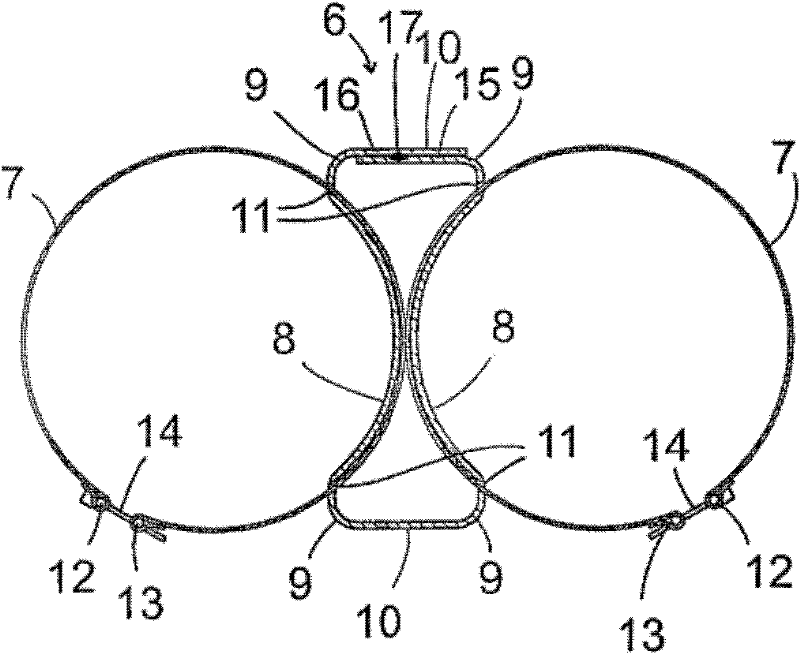

[0028] The structure of fuel tank module 2 or 3 can be in figure 2 It can be seen more clearly in the perspective view of . Between the two fuel containers 5 there is a support 6 formed from a rectangular blank, to which the fuel containers 5 are fastened in each case by means of two tensioning straps 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com