Ballast water processing system

A treatment system and ballast water technology, applied in water/sewage treatment, natural water treatment, water/sewage treatment equipment, etc. Reliable destruction or removal of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

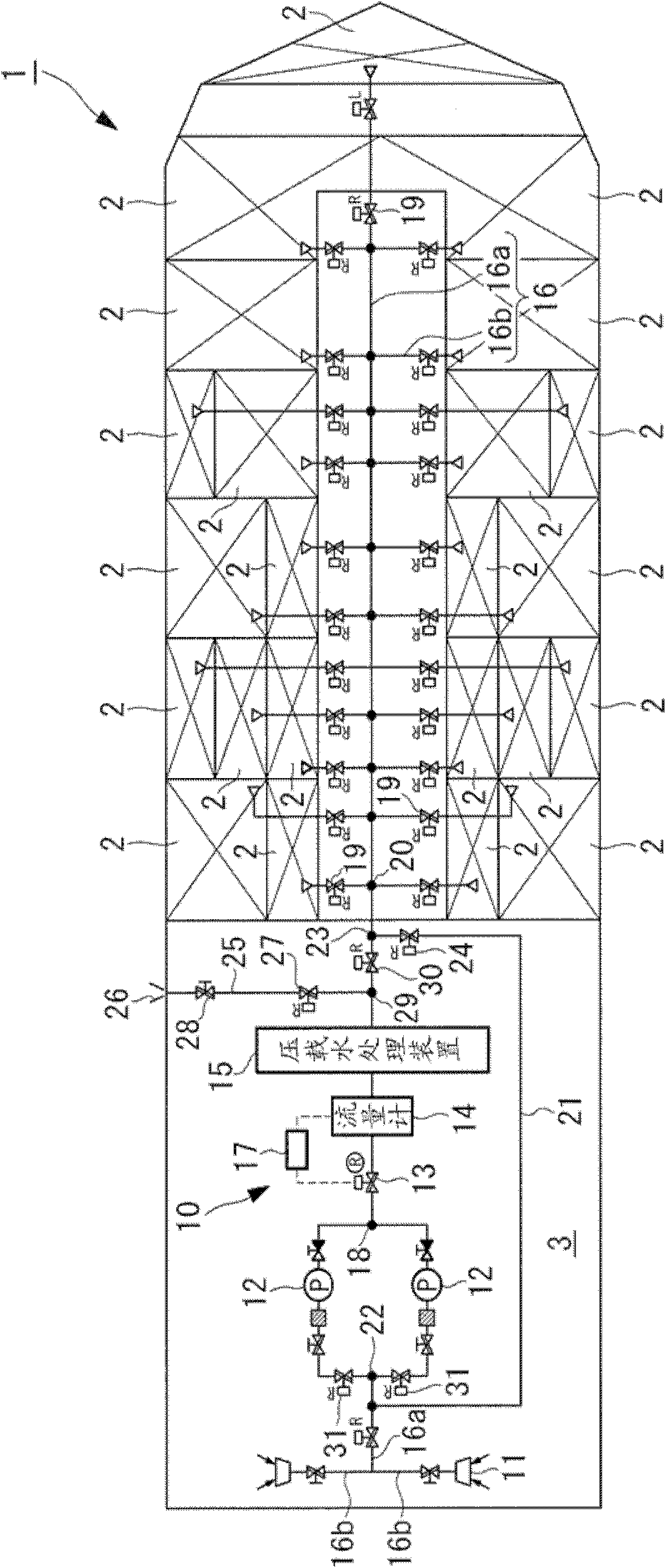

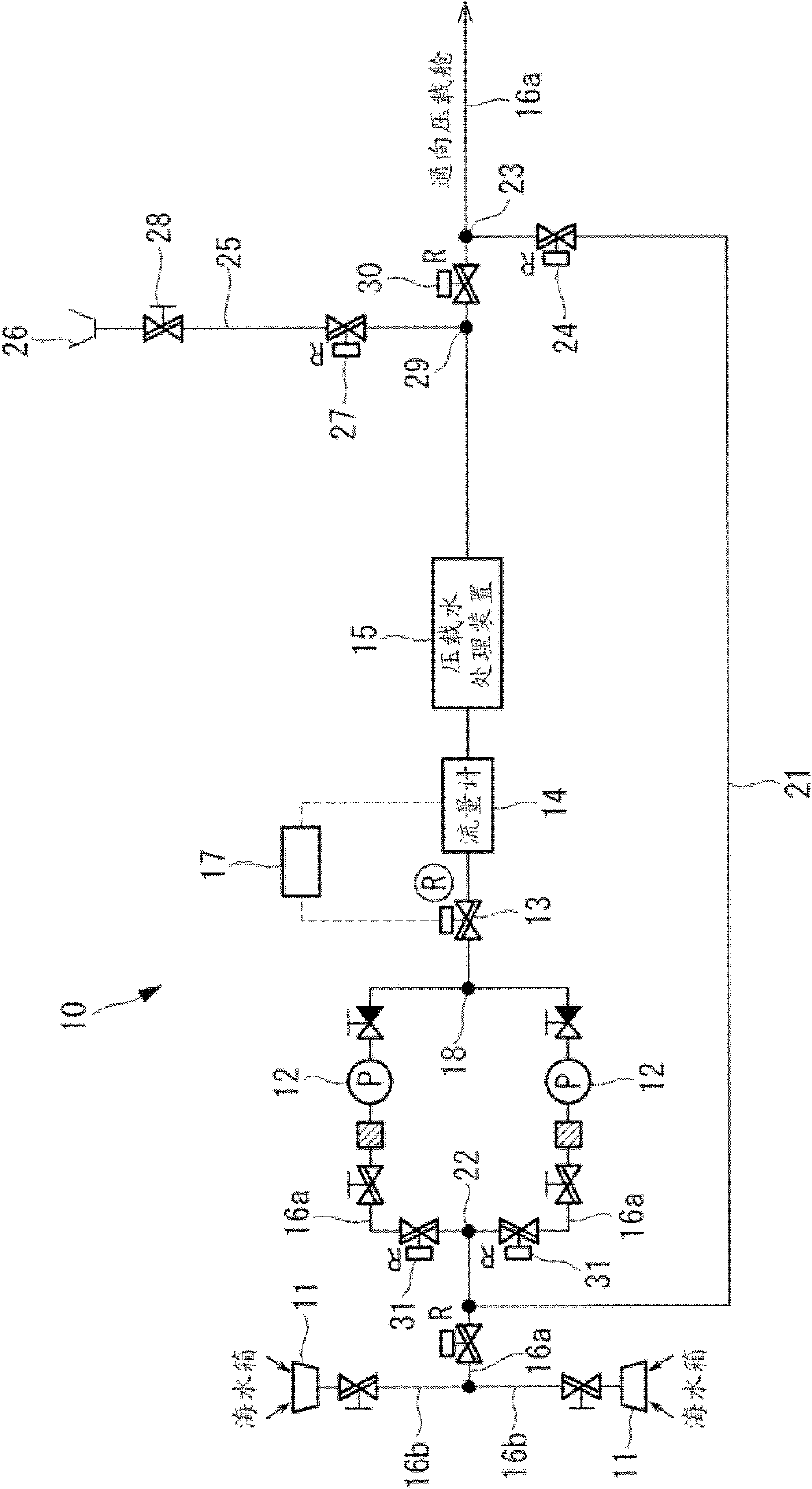

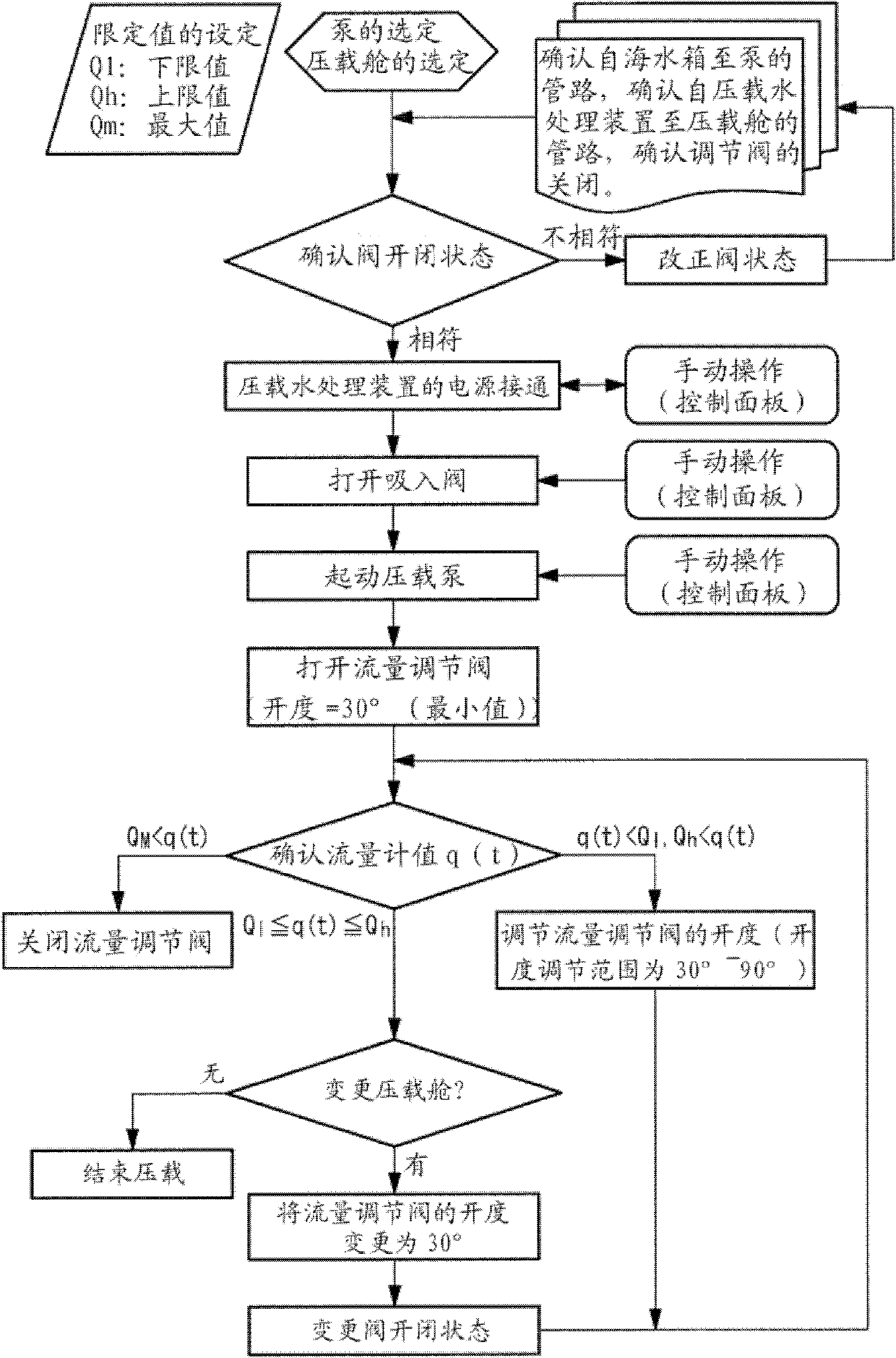

[0065] Below, refer to Figure 1 to Figure 3 A ballast water treatment system according to a first embodiment of the present invention will be described. figure 1 It is a figure which looked at the ship which mounted the ballast water treatment system of this embodiment from above, and is a figure which shows the schematic structure of the ballast water treatment system of this embodiment. figure 2 will be figure 1 Figure showing enlarged representation of the main part. image 3 It is a flowchart for demonstrating the operation procedure of the ballast water treatment system of this embodiment, and the control procedure of a controller.

[0066] The ballast water treatment system of the present invention is mounted on a ship (container ship, LNG ship, oil tanker, etc.) running system.

[0067] The ballast water treatment system 10 of the present embodiment has: a seawater tank (seawater suction port) 11, two ballast pumps 12, a flow regulating (control) valve 13, a flo...

no. 2 approach 〕

[0108] refer to Figure 4 A second embodiment of the ballast water treatment system of the present invention will be described. Figure 4 It is a figure which shows the schematic structure of the ballast water treatment system of this embodiment, and is the same as figure 2 same graph.

[0109] The ballast water treatment system 40 of this embodiment is different from the ballast water treatment system of the above-mentioned first embodiment in that an emergency stop valve 13 ′ is provided instead of the flow control valve 13 , and a bypass line 41 is provided. And bypass valve 42. The other components are the same as those of the above-mentioned first embodiment, and therefore descriptions of these components are omitted here.

[0110] In addition, the same code|symbol is attached|subjected to the same member as said 1st Embodiment.

[0111] The emergency stop valve 13' is a valve whose opening is 0° under the control of the controller 17 when the data measured by the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com