A packaging cardboard regeneration beating device

A technology for packaging cardboard and beating barrels, which is applied in pulp beating methods, papermaking, textiles, and papermaking. It can solve the problems of burning out the agitator, increasing the cost of recycling production, and large rotation resistance of the agitator to ensure stability. The effect of increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

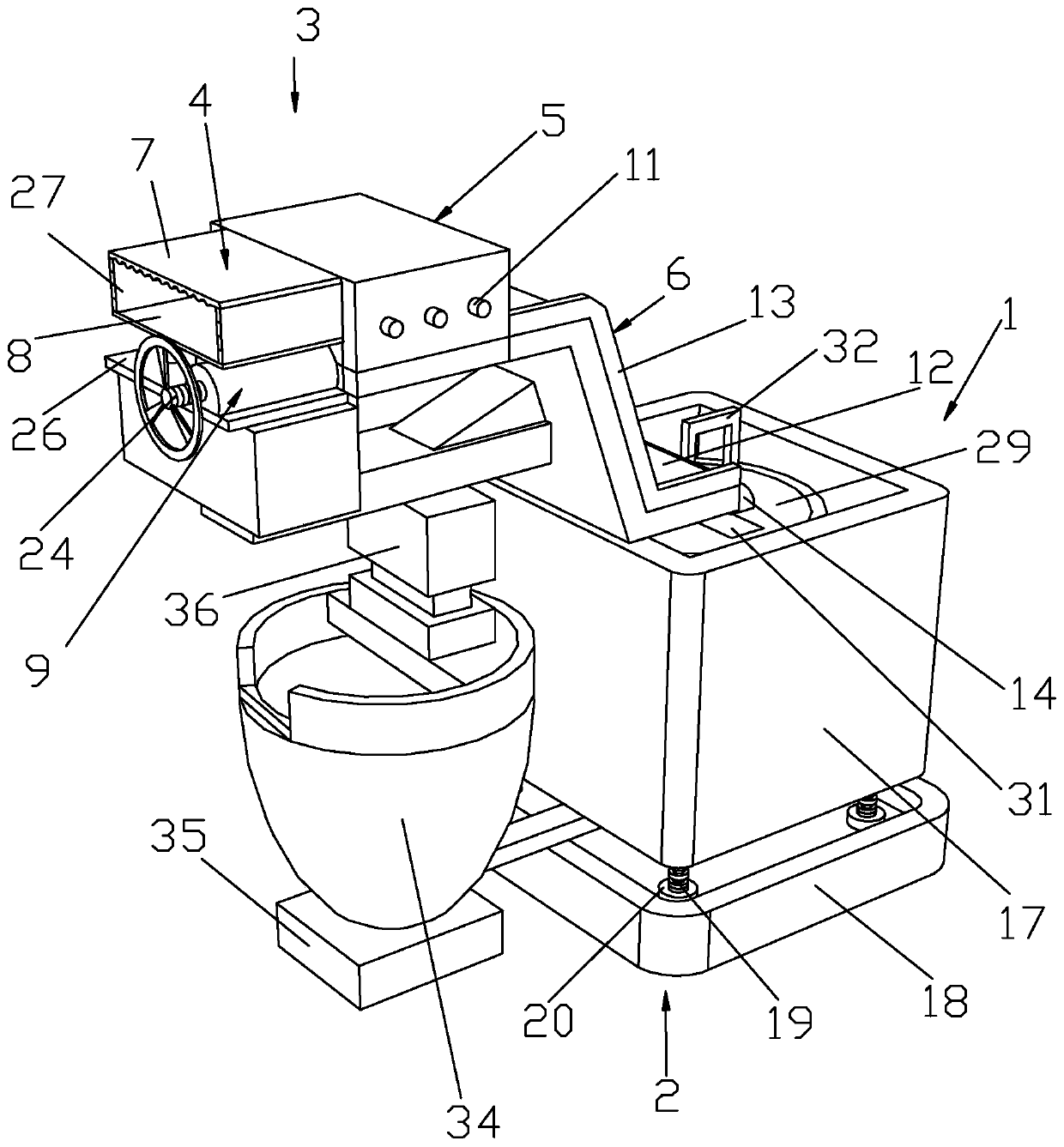

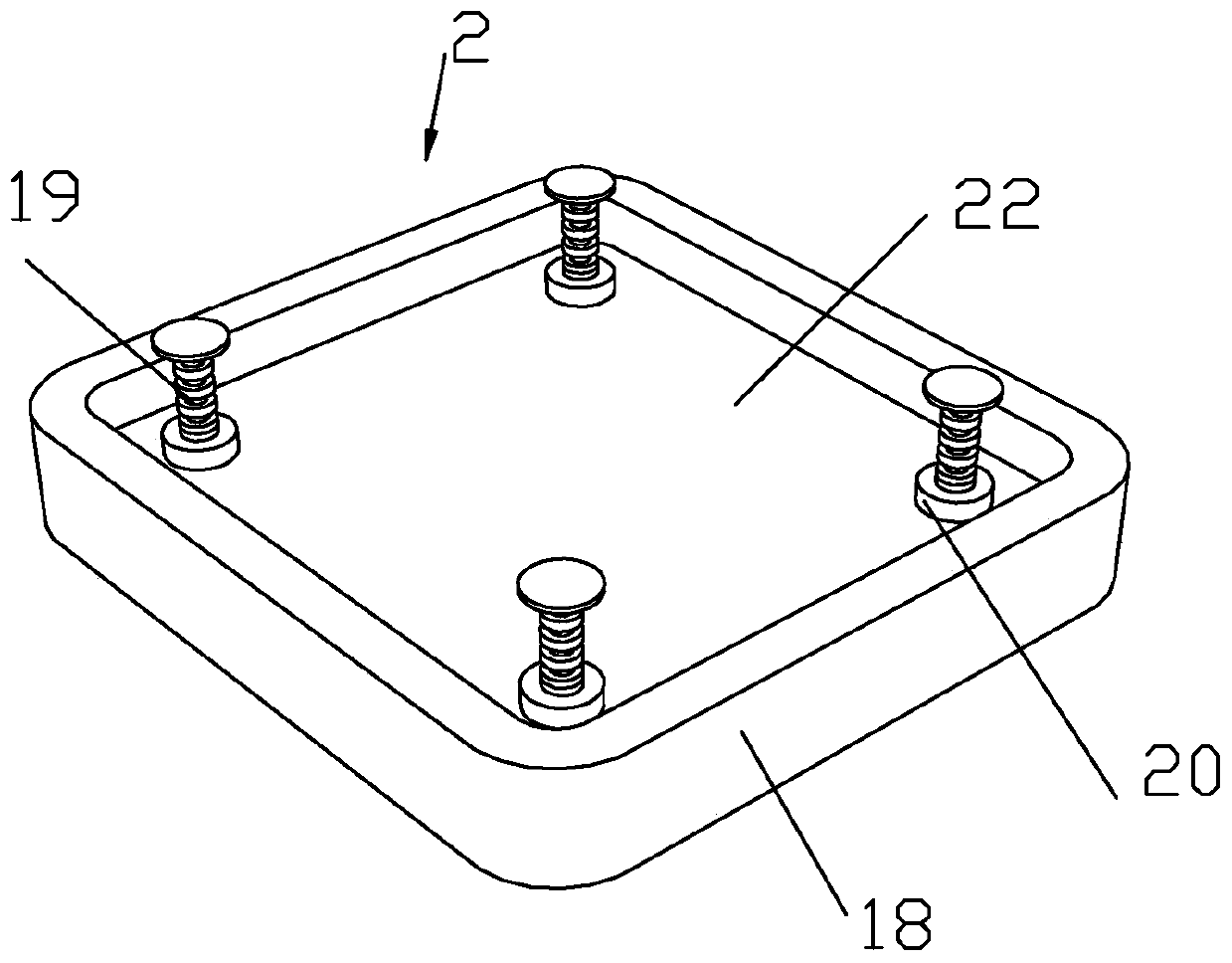

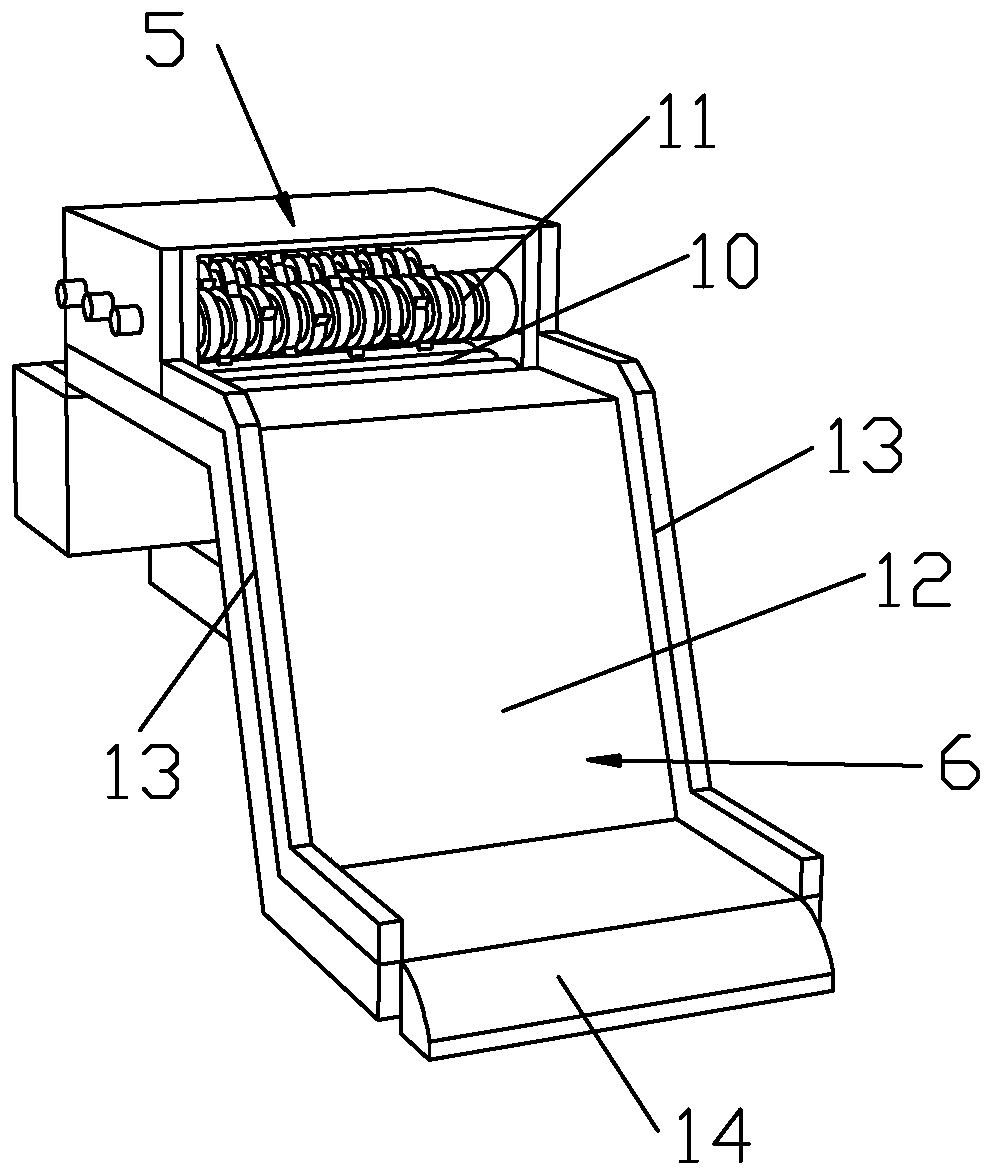

[0028] Such as Figure 1 to Figure 8 As shown, in order to solve the above technical problems, the present invention adopts the following technical solutions: a packaging cardboard recycling beating device, including a pulp chamber 1, a vibration platform 2 and a shredded paper passage 3, the shredded paper passage 3 includes a rolling inlet 4, shredded paper The chamber 5 and the guide channel 6, the roller inlet 4 includes an upper partition 7, a lower partition 8 and a height adjuster 9, the upper partition 7 is fixedly connected with the height adjuster 9, and the lower partition 8 is arranged on the top of the upper partition 7. Below, the lower partition 8 is fixedly connected with the height adjuster 9, the shredding chamber 5 includes a conveying roller 10 and a rotating shredding roller 11, the rotating shredding roller 11 is installed on the conveying roller 10, and the rotation of the rotating shredding roller 11 The direction is opposite to the moving direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com