Improved soaking type vertical pump structure

A pump and vertical technology, which is applied in the field of water-immersed vertical pump structure improvement, can solve the problems of reducing vapor molecular deposition, reducing structural strength, and letting joints leak, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

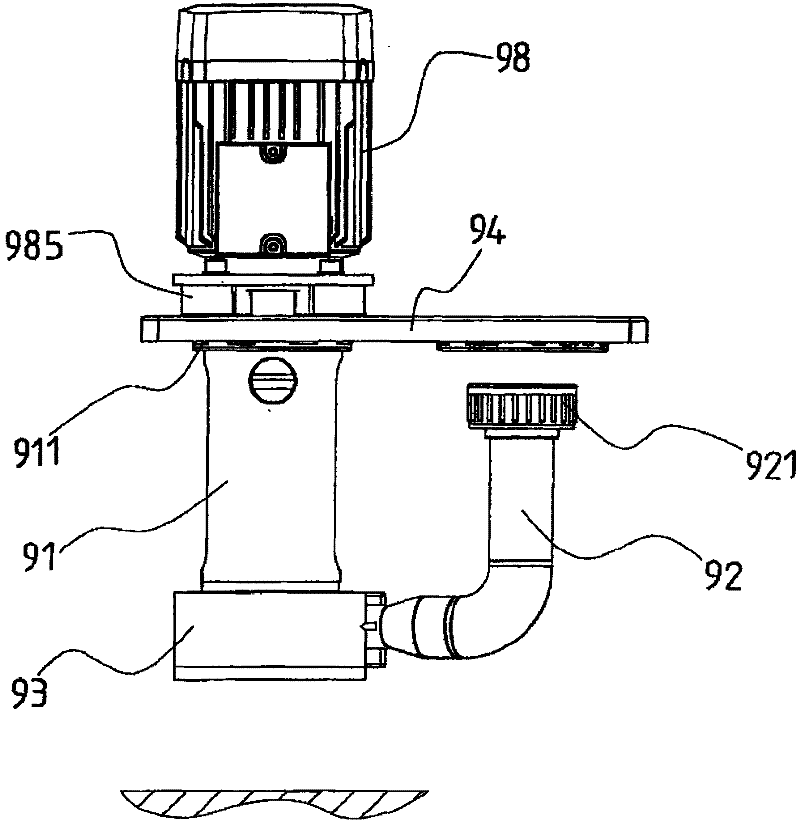

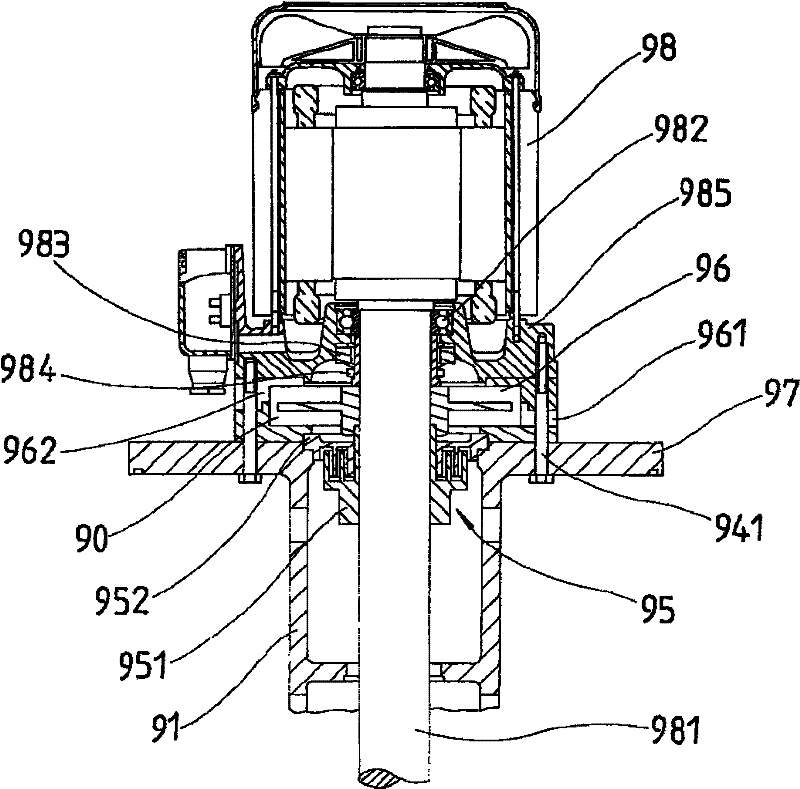

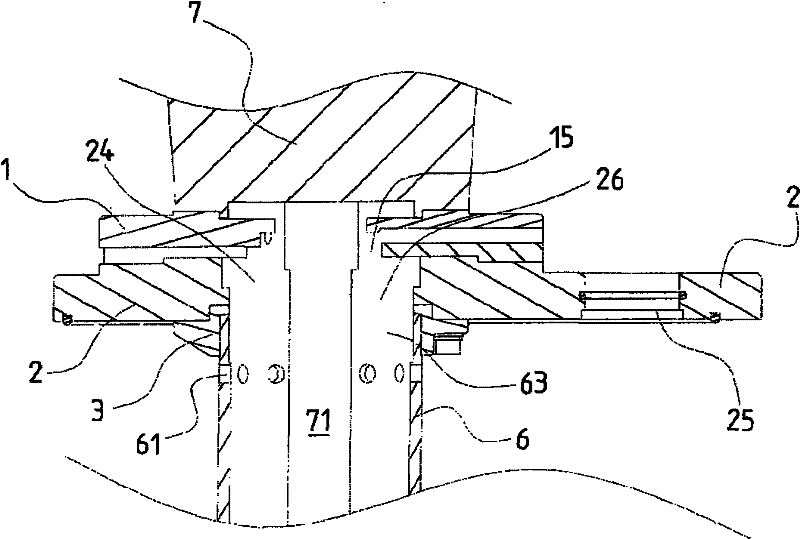

[0100] Figure 3A and 3B It is the position and function description of the main device of the present invention, such as Figure 3A As shown, the motor connection plate 1 and the support plate 2 are installed under the motor 7, and the pump connection group 3 is welded above the support tube 6 to connect with the support plate 2. The central hole 15 of the motor connection plate, the central hole 26 of the support plate and the The opening 63 above the support pipe constructs a chamber space 24, such as Figure 3B As shown, the chamber space 24 is located at the upper end of the motor shaft 71 for placing the positive pressure exhaust shaft seal device 5 , and the outlet hole 25 of the support plate is used for installing the outlet pipe fixing group 81 .

[0101] Figure 3B As shown, the pump connection group 3 and the support pipe 6 are firmly welded together, and the outlet pipe fixing group 81 and the lower joint 821 are firmly welded on the outlet pipe 8, and the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com