Package structure for light-emitting diode

A technology for light emitting diodes and packaging structures, which is applied to electrical components, electric solid state devices, circuits, etc., can solve the problems of uneven light output in the packaging structure of light emitting diodes, and achieve the effect of uniform light mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

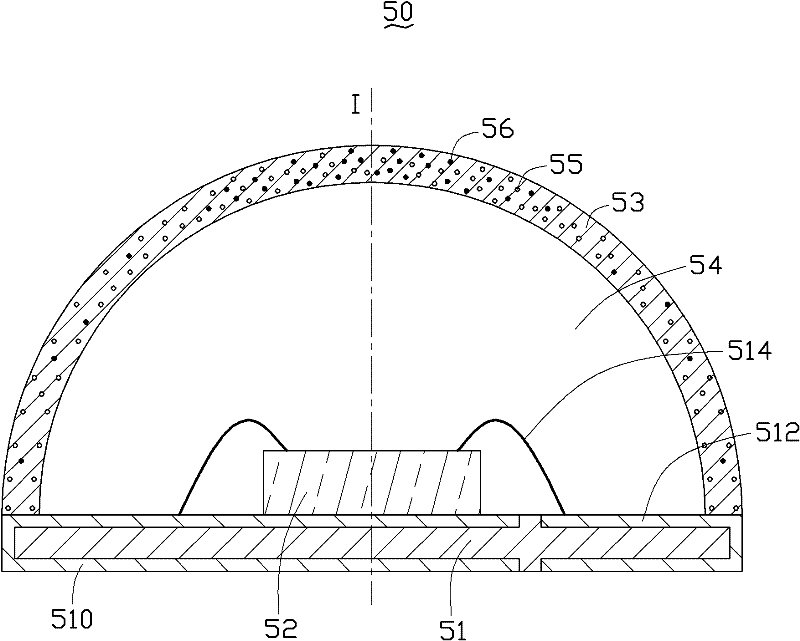

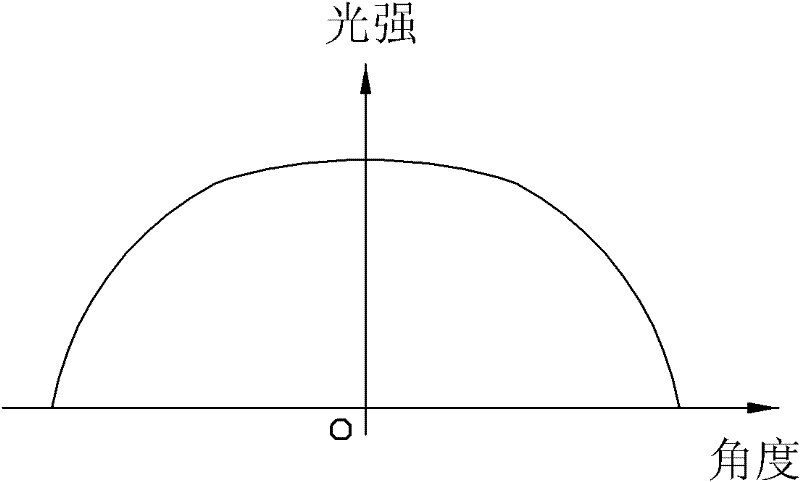

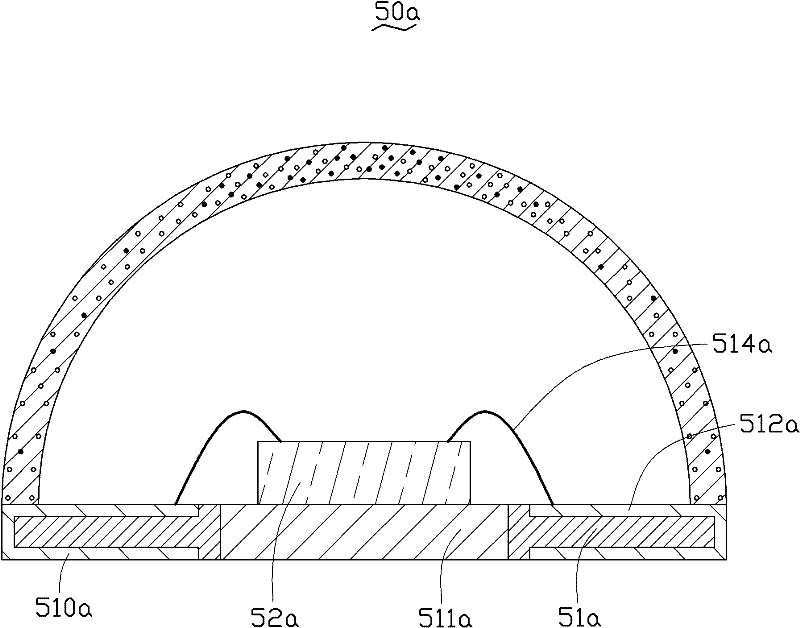

[0023] see figure 1 The LED packaging structure 50 provided in the first embodiment of the present invention includes a substrate 51, a LED chip 52 mounted on the substrate 51, a package body 53 sealed above the LED chip 52, and a package body adsorbed on the package. The light scattering structure on the body 53. Phosphor powder 55 is distributed inside the package body 53 . The light scattering intensity of the light scattering structure increases and decreases in the same direction as the intensity of light irradiated by the light emitting diode chip 52 on each area of the package body 53 .

[0024] Described substrate 51 can adopt aluminum oxide (Al 2 o 3 ), silicon (Si), silicon carbide (SiC), ceramic (ceramic), polymer (polymer) or insulating quartz and other materials. The substrate 51 includes a circuit structure electrically connected to the LED chip 52 . The circuit structure includes a first electrode 510 and a second electrode 512 . The LED chip 52 is dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com