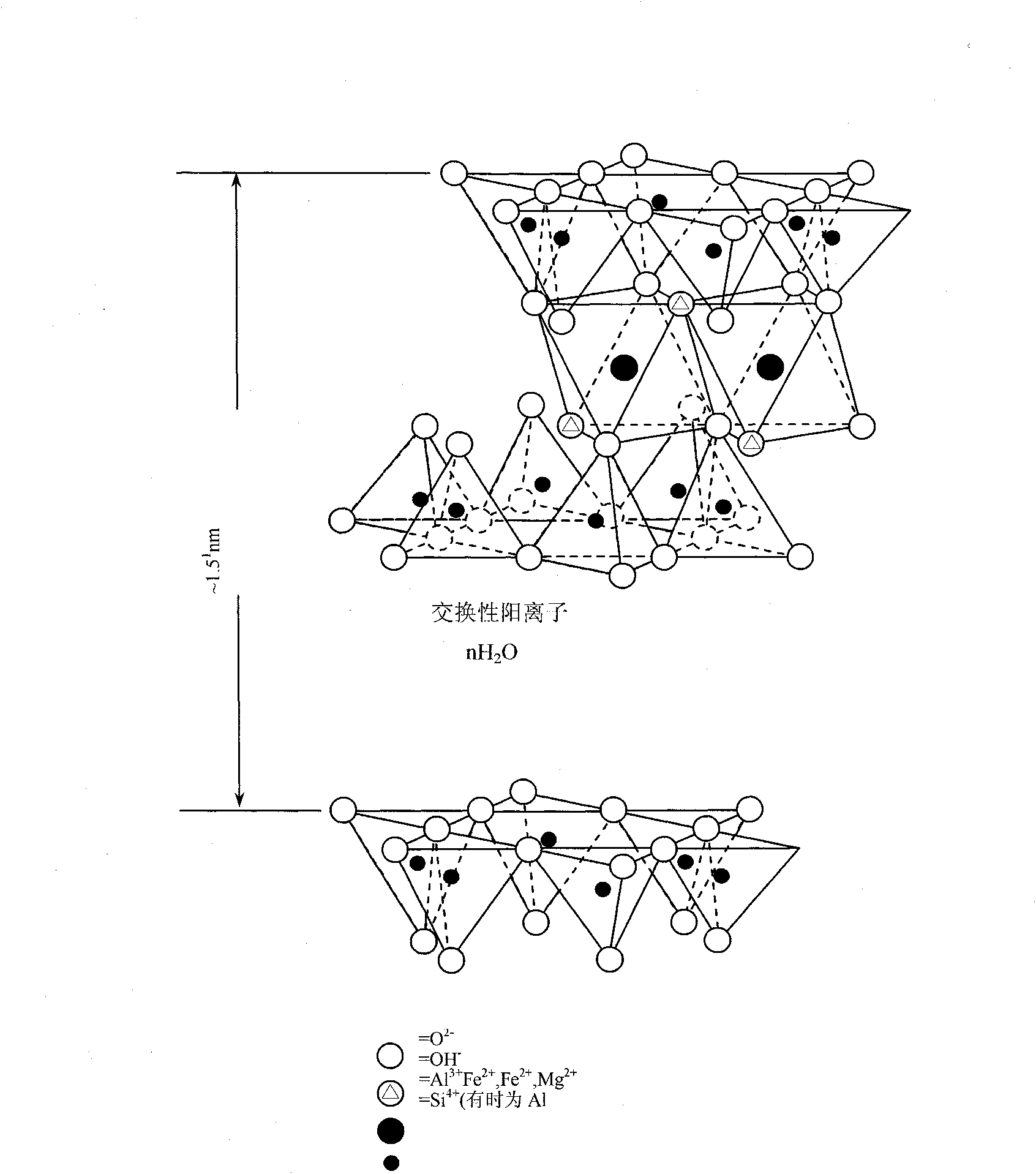

Anionic-cationic composite intercalation type organic montmorillonite material and preparation method thereof

An organic montmorillonite and composite intercalation technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of cumbersome process route, poor product stability, complex preparation process, etc. High stability and high degree of peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method for preparing cation-anion composite intercalation type organic montmorillonite, which includes the following steps:

[0032] A. Purified montmorillonite: Purify natural calcium-based montmorillonite;

[0033] B. Hydration treatment of montmorillonite: the purified montmorillonite is made into an aqueous suspension, and the hydration treatment is carried out by means of mechanical stirring and ultrasonic mixing;

[0034] C. Preparation of cation-anion composite intercalation type organic montmorillonite material: the fully hydrated montmorillonite hydration liquid is marked as liquid A, the organic cationic surfactant is added to liquid A and ultrasonic dispersion is performed, Subsequent mechanical stirring is followed to obtain liquid B, and then the anionic surfactant is added to liquid B and the machine is used for ultrasonic dispersion, followed by mechanical stirring, standing at a constant temperature, separation and drying to obt...

Embodiment 1

[0074] Example 1 Purification of Montmorillonite

[0075] ① Crush the calcium-based montmorillonite ore with a ball mill and pass through a 200-mesh sieve to obtain montmorillonite powder;

[0076] ②Weigh 80g of montmorillonite powder and dissolve it in 8L of distilled water (packed in a bucket), stir with an electric stirrer for 20 minutes, prepare the montmorillonite into a suspension with a "concentration" not exceeding 10g / L, and continue to stand still at room temperature. Leave it for 8 hours and take out the part with a height of <10cm with a siphon;

[0077] ③ Take the upper 10cm suspension, centrifuge, and vacuum dry (70℃) to obtain refined montmorillonite;

[0078] ④Add distilled water again to the remaining part, restore the volume to the original volume and continue stirring for 20 minutes to disperse the particles larger than 2μm that are not "disassembled", and then take them out after 8 hours. Repeat this several times until the remaining part is re-added with distill...

Embodiment 2

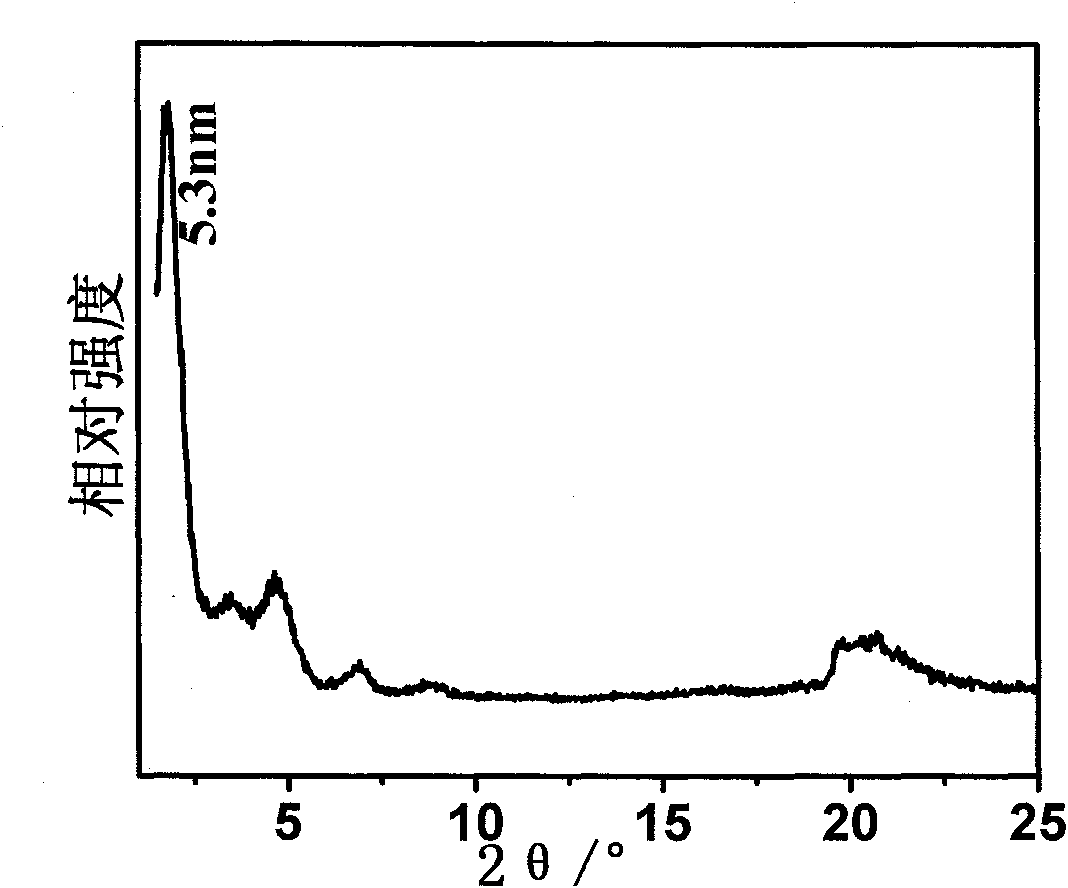

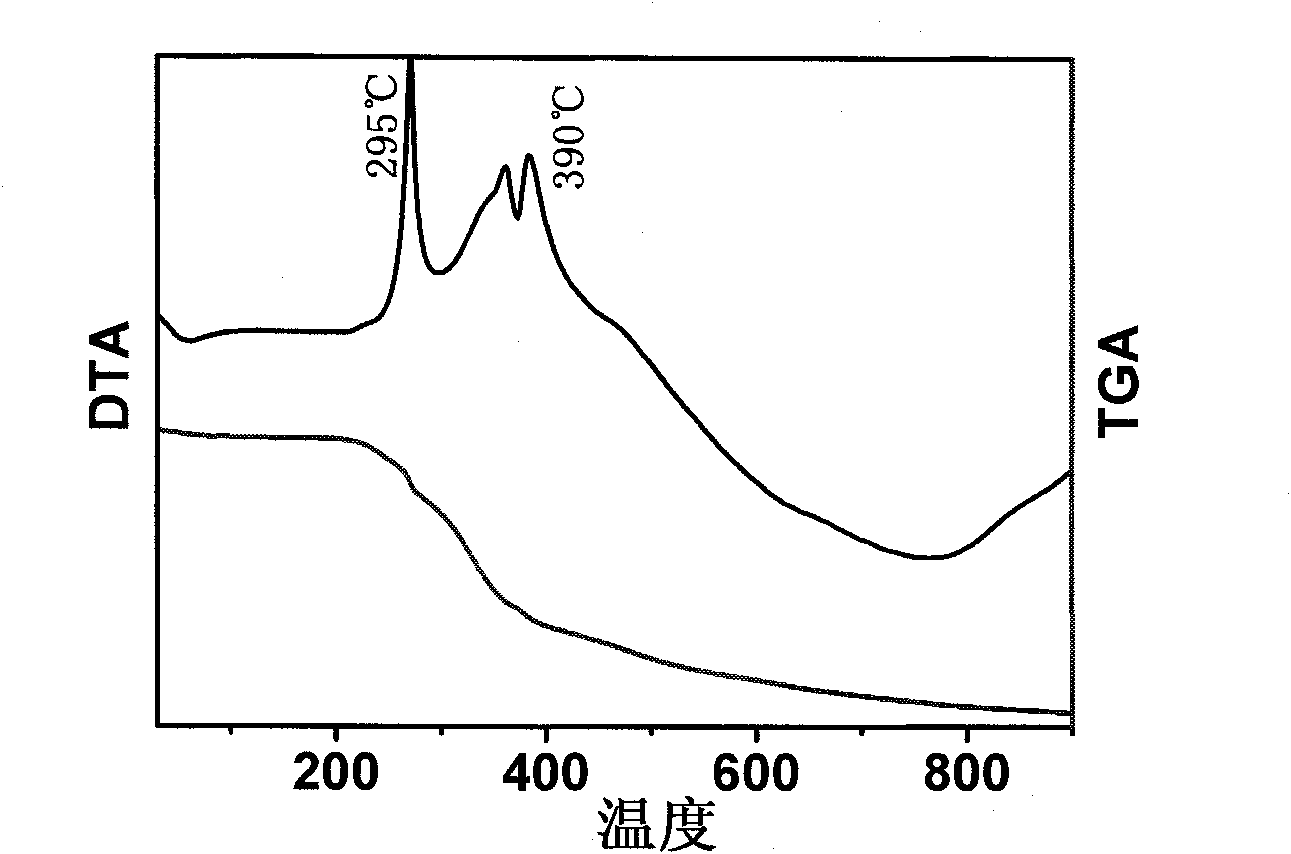

[0079] Example 2 Preparation of cation-anion composite intercalation type organic montmorillonite

[0080] Add 5 g of calcium-based montmorillonite with a cation exchange capacity of 88 meq / 100g and a particle size of 200 mesh sieve obtained in Example 1 into a three-necked flask containing 100 ml of water, and hydrate with ultrasonic and mechanical stirring. One hour is recorded as A solution, 3g cetyltrimethylammonium bromide is slowly added to A solution, after 10 minutes of ultrasonic dispersion, the ultrasonic is stopped, and the mechanical stirring is continued for 2 hours, then 1.8g of dodecyl sulfonic acid is added Sodium is turned on and ultrasonic for 10 minutes and mechanical stirring is continued for 1 hour. The stirring is stopped, cooled to room temperature and centrifuged. The sample is washed once with deionized water, dried in a drying oven at 80°C for several hours, and ground to pass a 200 mesh sieve. The cation-anion composite intercalation type organic montm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com