Self-sealing double-rubber-ring pipeline flexible connector

An automatic sealing and flexible interface technology, applied in the direction of pipes/pipe joints/fittings, through components, mechanical equipment, etc., can solve the problems of reducing rebound force, loss of sealing ability, adhesion, etc., to solve leakage, avoid undercut and Effect of adhesion damage and leakage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

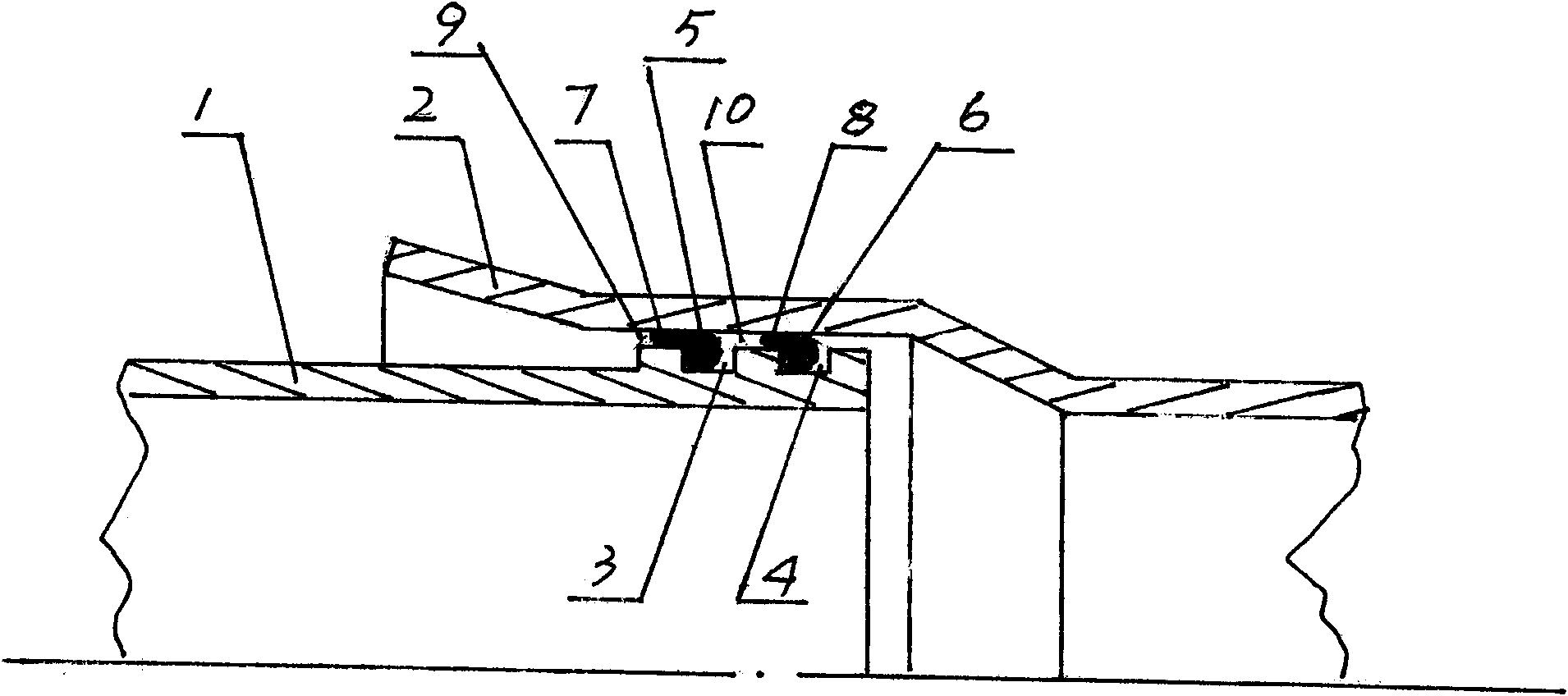

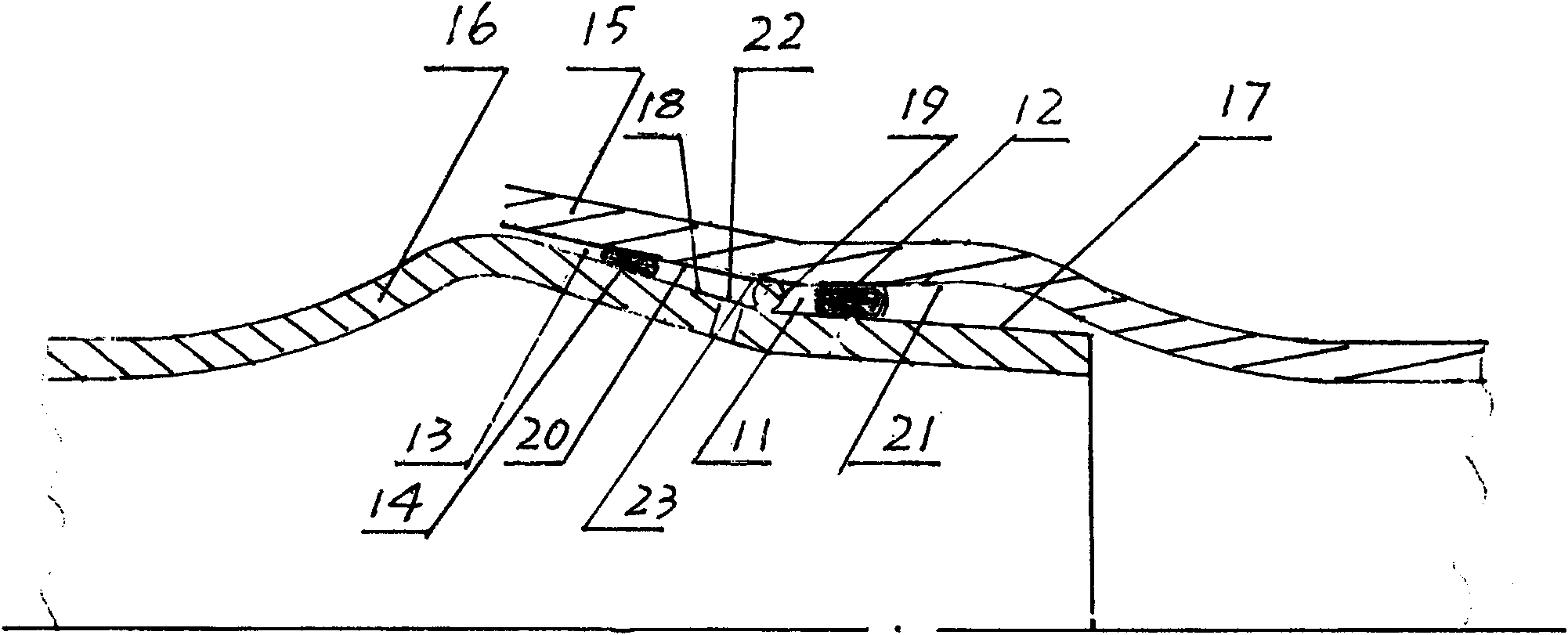

[0011] The automatic sealing double sealing rubber ring pipeline flexible interface is composed of the plug 16, the socket 15 and the rubber rings 12, 14. The rubber ring is in the front and rear wedge-shaped sealed cavities 11, 13 formed after the plugs are inserted into each other. Head and plug connection interface.

[0012] The end of the plug 16 has a front outer conical surface 17 with a conicity less than 10°. The rear end of the front outer conical surface 17 has a rear outer conical surface 18 with a greater conicity than the front outer conical surface. The front and rear conical surfaces 17 There is a convex rigid ring 19 at the junction of, 18, the outer diameter of the rigid ring 19 is slightly larger than the inner diameter of the inner cylindrical surface 21 of the socket, and the end of the socket 15 has a section of taper less than the outer conical surface 18 of the plug. Conical inner conical surface 20. Behind the inner conical surface 20 is a section of inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com