Handheld parameter calibration equipment for tower crane monitoring system

A monitoring system and parameter technology, applied in the field of hand-held calibration equipment for tower crane monitoring system parameters, can solve the problem of increasing the labor workload and labor intensity of tower crane monitoring parameter initial calibration personnel, life safety threats to parameter setting personnel, and increased manpower and time costs and other issues to achieve the effect of reducing labor workload, saving manpower and time costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

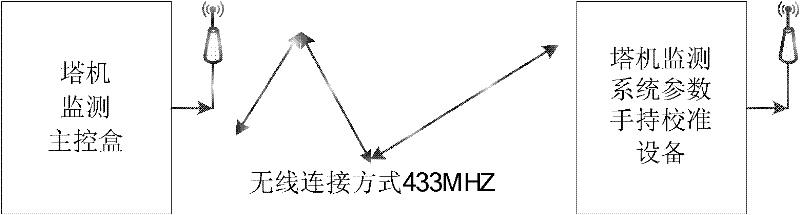

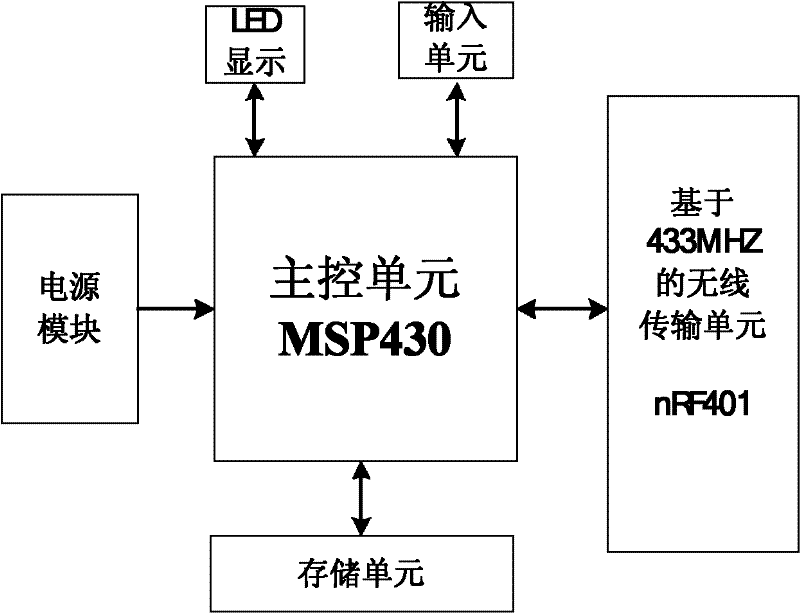

[0019] Embodiment 1: The hand-held calibration device for parameters of the tower crane monitoring system according to the present invention includes a main control box and a hand-held calibration device.

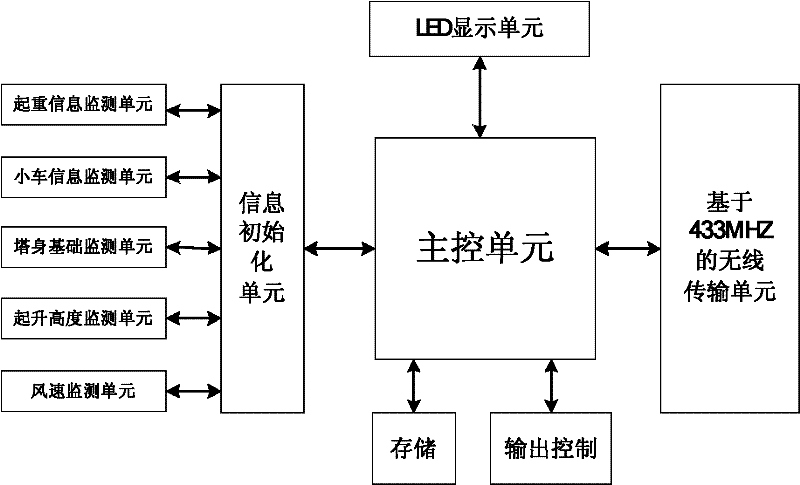

[0020] Among them, the main control box is installed in the monitoring system of tower base, which is used to collect various sensory data and display them in the main control box; the main control box includes the main control unit, information initialization unit, storage control unit, 433MHZ wireless transmission unit and LED display Unit, 433MHZ wireless transmission unit and corresponding to a unique device ID number, used to receive the signal of the handheld calibration device; after the 433MHZ wireless transmission unit receives the information sent by the handheld calibration device, it transmits it to the main control unit, and the main control unit processes After that, it is written into the storage control unit and sent to the information initialization unit, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com