Glass and press forming and drilling method thereof

A technology of press molding and drilling method, applied in glass manufacturing equipment, glass production, glass cutting device, etc., can solve the problems of poor flatness of bottom sealing surface, unsatisfactory sealing effect, low labor productivity, etc., and achieve high flatness , Reduce labor workload, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

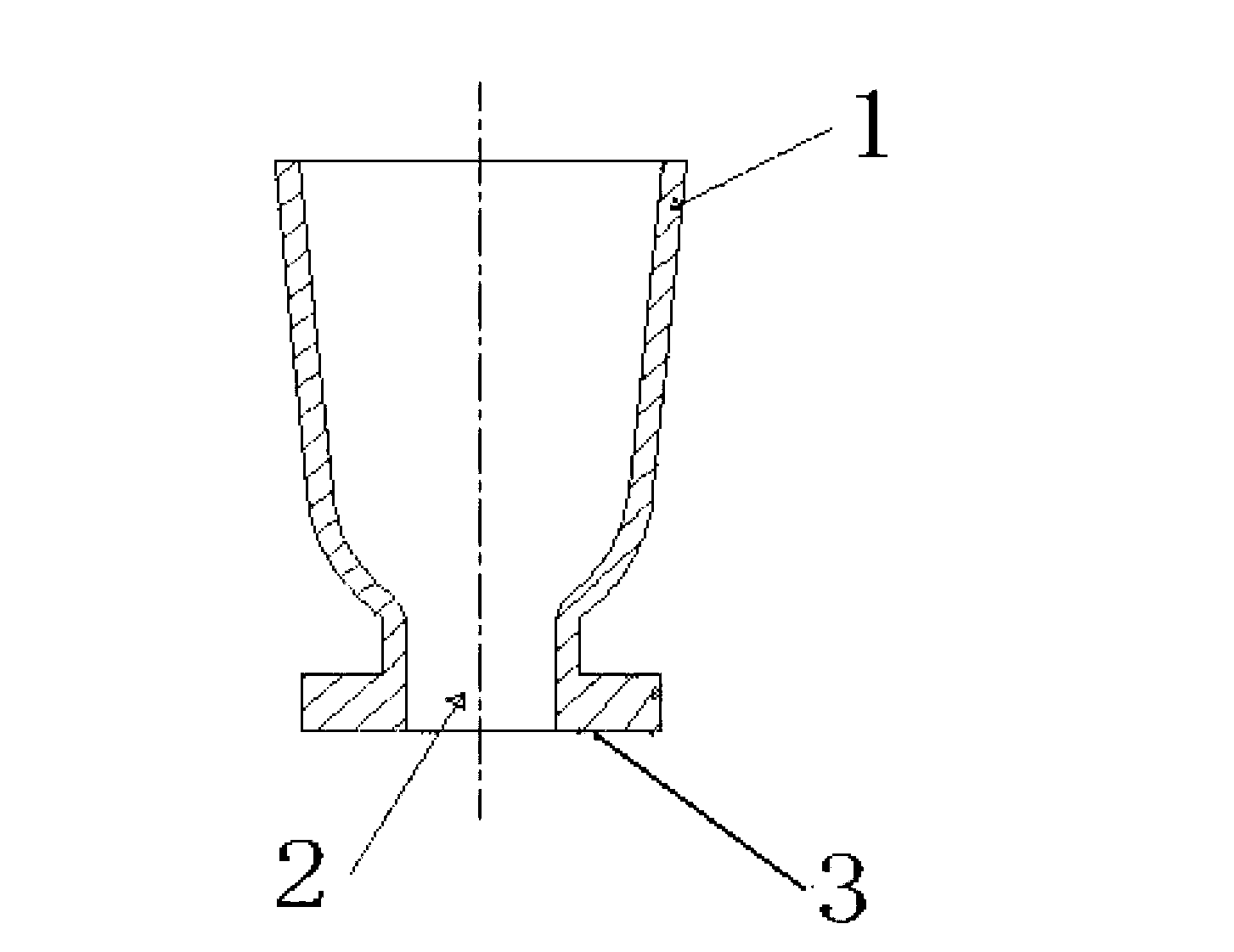

[0013] See figure 1 , which is a schematic cross-sectional structure diagram of a glass in an embodiment of the present invention.

[0014] The glass cup provided in this embodiment includes a glass cup body 1 and a bottom sealing surface 3, the bottom sealing surface 3 is connected to the glass cup body 1, a cavity is provided inside the glass cup body 1, and a cavity is provided on the bottom sealing surface 3 for installation. The through hole 2 of the rotary tool communicates with the cavity. Wherein, the glass cup body 1 and the bottom sealing surface 3 are integrally formed by pressing, and the through hole 2 of the bottom sealing surface 3 is formed by drilling.

[0015] In addition, the present invention also provides a method for pressing, forming and drilling a glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com