Crank connecting rod type ball net drawing device

A technology of crank connecting rod and ball collecting net is applied in the directions of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc. Function and quality issues, to achieve the effect of high rigidity and strength, easy processing and assembly, function and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

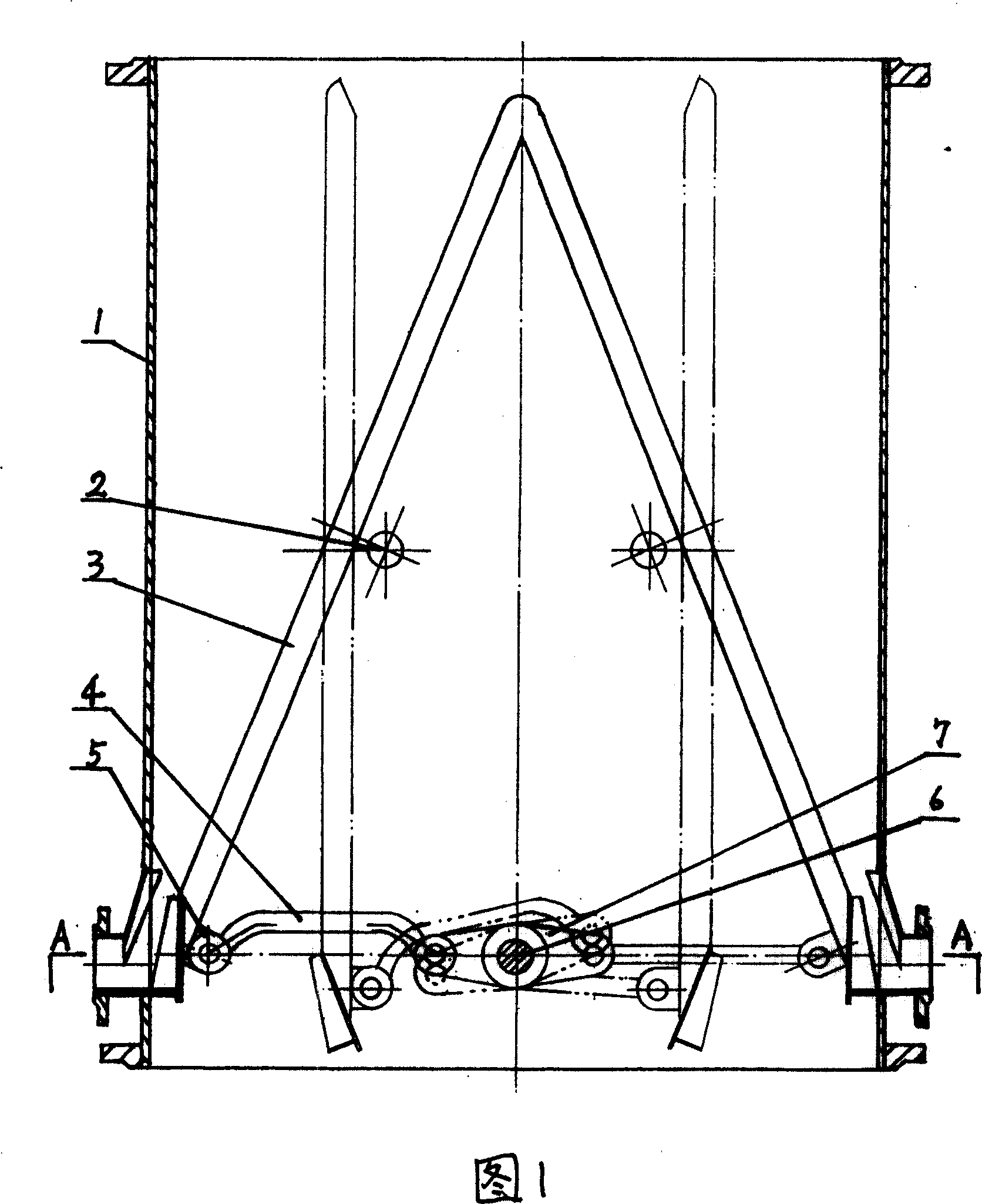

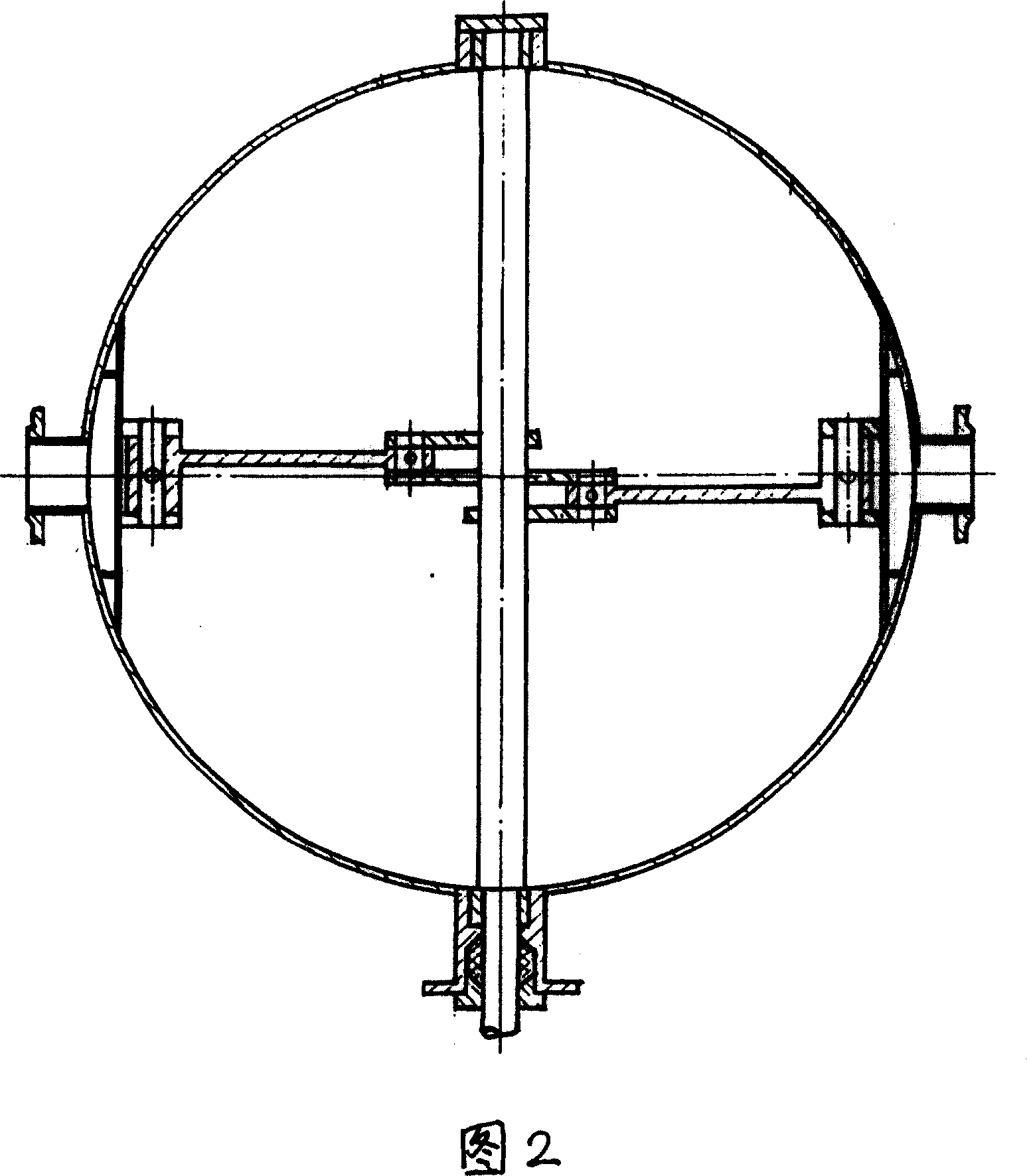

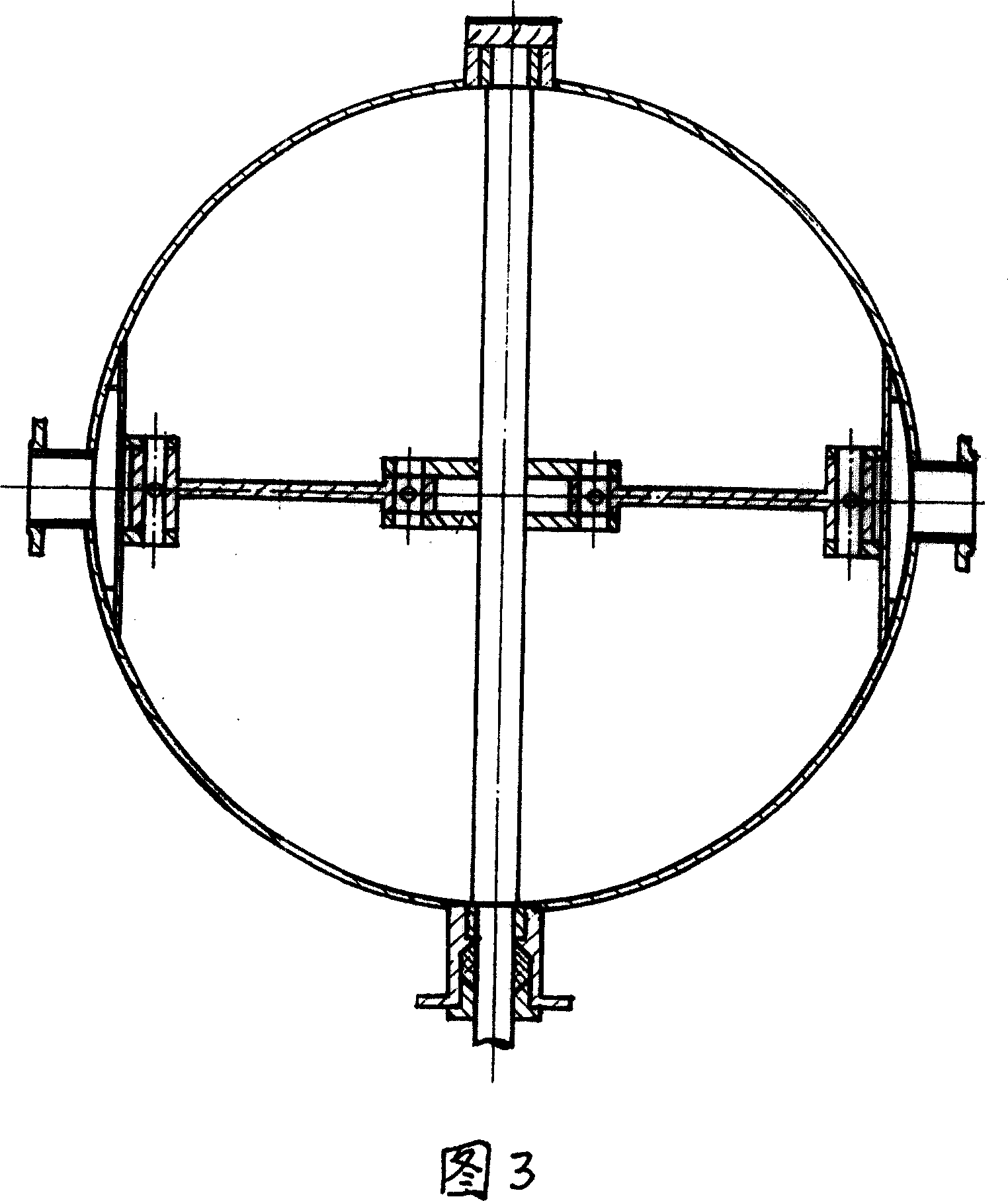

[0021] As shown in Figures 1 and 2, the crank-link type ball net collection device according to the present invention has a double net plate structure, including a ball collection cylinder 1, a net plate 3, a net plate rotating shaft 2, a rubber ball outlet pipe, and a flow guide. plate, transmission, executive device and control device, the rotating shaft 2 of the screen plate is placed on the cylinder 1, the lower part of the screen plate 3 is provided with a swing support 5, and the execution device is a crank-link mechanism, and the swing support 5 is connected to the actuator The connecting rod 4 of the device is hinged, the other end of the connecting rod 4 is hinged with the crank 7, and the crank shaft 6 of the transmission device is connected with the operating device outside the ball receiving tube, and the crank shaft 6 is the crank through shaft arranged on the ball receiving tube 1 , the shape of the connecting rod 4 adapts to the swing angle of the crank 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com