Linear control device for segment prefabricated assembled straight line bridge and using method

A linear control, prefabricated assembly technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of heavy tasks, complicated coordinate conversion process, and difficulty in fast assembly and construction of segmental beams, etc., so as to facilitate rapid reading and reduce Time cost and labor cost, the effect of reducing labor workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

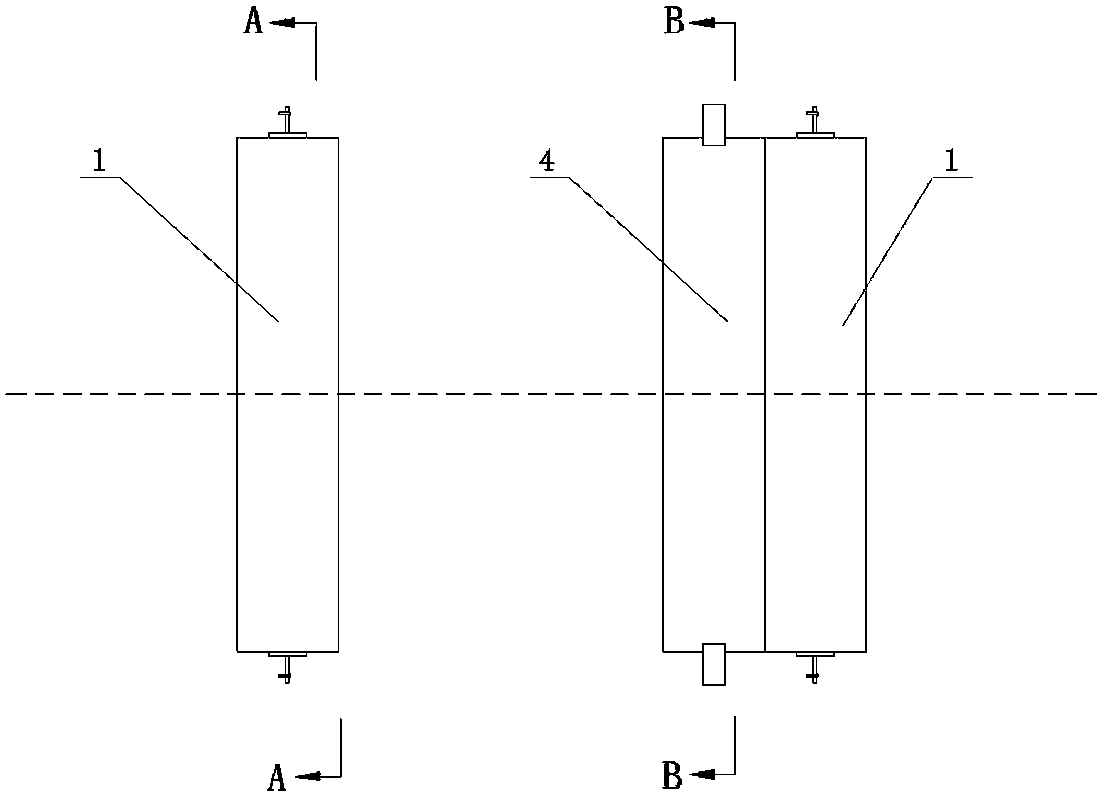

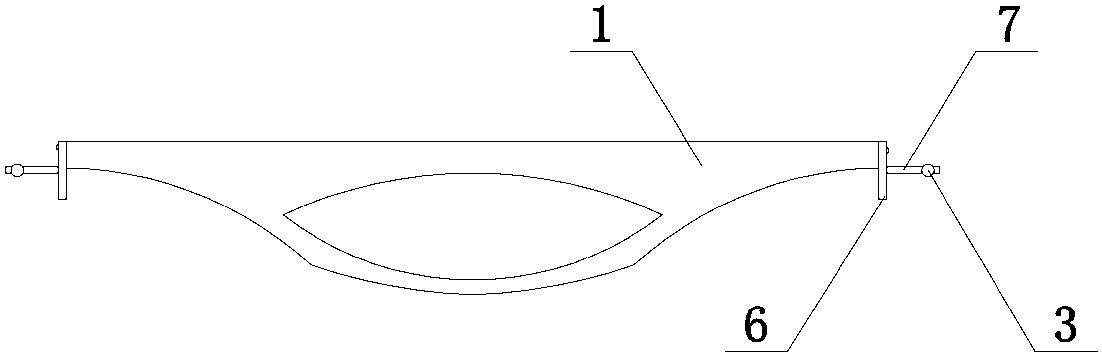

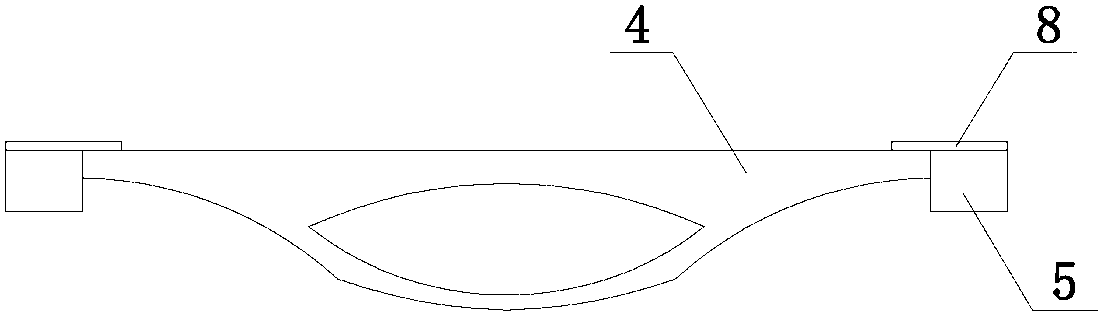

[0030] Such as Figure 1~5 As shown, a device for linear control of segmental prefabricated linear bridges, including a first fixing device, a laser emitter 2 on the first fixing device, a second fixing device, and a first plexiglass on the second fixing device Plate 5, the first fixing device includes a first fixing plate 6 and a first steel rod 7, the first fixing plate 6 is provided with a first screw hole 61, and the first fixing plate 6 can be backed by a screw through the first screw hole 61 The plate surface is closely attached to and fixed on the outer side of the outrigger of the cast-in-place segment 1. The front plate surface of the first fixed plate 6 is vertical and fixedly provided with the first steel rod 7, and the head of the first steel rod 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com