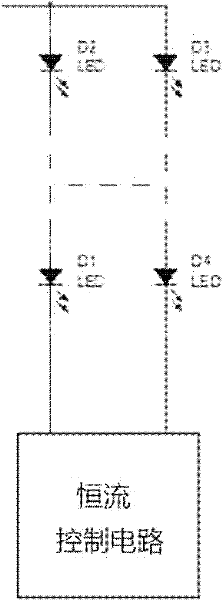

LED (light emitting diode) backlight driving method, liquid crystal display device and LED backlight driving circuit

A backlight drive circuit and liquid crystal display device technology, applied to lighting devices, lamp circuit layout, light sources, etc., can solve the problems of low power supply efficiency, loss, and temperature rise of constant current control circuits, so as to reduce the pressure difference and improve Efficiency and loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

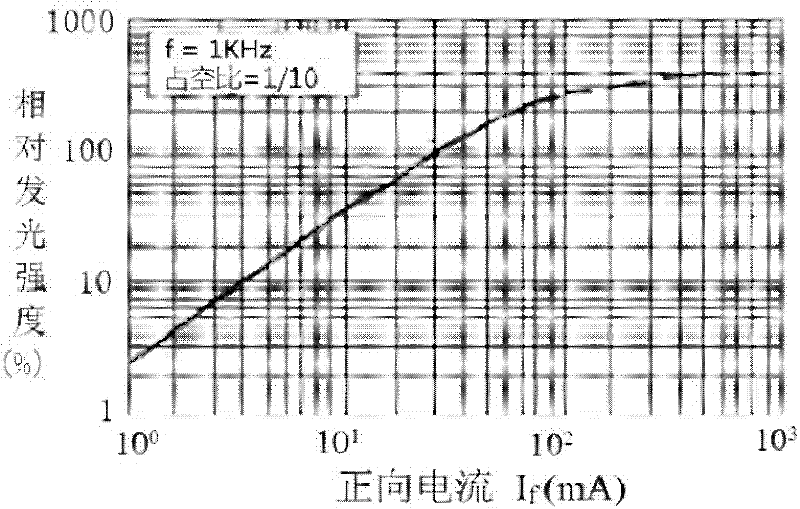

[0035] First execute step A: based on the minimum voltage, detect the voltage value of the LED string 1 with the smallest voltage, and adjust the current of each LED string 1 so that the voltage of each LED string 1 is the above-mentioned voltage value. Step B is then executed: by adjusting the current duty cycle of the corresponding LED string 1 , the effective value of the current of each LED string 1 reaches the preset brightness requirement. In this method, the current duty cycle of the LED string 1 is preferably less than 80%, so as to ensure a wide adjustment range. Based on the minimum voltage value of LED string 1, lower power consumption can be obtained.

[0036] In order to prevent that the brightness of the LED cannot be guaranteed to meet the requirements when the duty cycle is adjusted to the maximum value, the step B may be followed by a step C: feeding back the effective value of the current after the current equalization to the power supply for the LED string 1...

Embodiment 2

[0039] Similarly, step A is executed first, and the step A includes the following steps: detecting the voltage value of the LED string 1 with the highest voltage, and adjusting the current of each LED string 1 so that the voltage of each LED string 1 is the above-mentioned voltage value. Step B is then executed: by adjusting the current duty cycle of the corresponding LED string 1 , the effective value of the current of each LED string 1 reaches the preset brightness requirement. This embodiment is based on the maximum voltage value of the LED string 1 .

[0040]Similarly, in order to ensure that the brightness of the LED meets the requirements, the step B is followed by a step C: feeding back the current effective value after the current equalization to the power supply module that supplies power to the LED string 1, and the power module is effective according to the current required by the current brightness. Adjust the output voltage in real time, and then repeat steps A~C....

Embodiment 3

[0043] Similarly, step A is executed first, and the step A includes the following steps: detecting and calculating the average voltage of each LED string 1 , and adjusting the current of each LED string 1 so that the voltage of each LED string 1 is the above-mentioned average voltage. Step B is then executed: by adjusting the current duty cycle of the corresponding LED string 1 , the effective value of the current of each LED string 1 reaches the preset brightness requirement. In this embodiment, the average voltage of the LED string 1 is used as a reference, and a wide adjustment range can be obtained.

[0044] Similarly, in order to ensure that the brightness of the LED meets the requirements, the step B is followed by a step C: feeding back the current effective value after the current equalization to the power supply module that supplies power to the LED string 1, and the power module is effective according to the current required by the current brightness. Adjust the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com