Primary neutron source part for starting nuclear reactor

A nuclear reactor and neutron source technology, applied in the field of radioisotope preparation, can solve the problems of difficult cleaning and transportation of neutron source parts, achieve long-term effective operation, improve radiation safety performance, and save space for parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

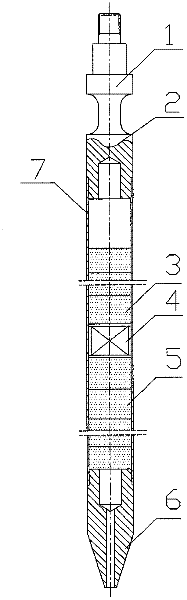

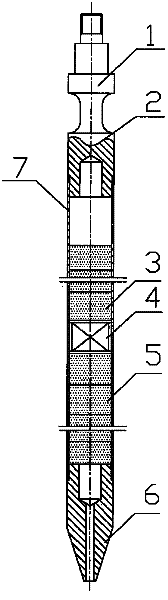

[0022] One-time assembly of neutron source components: first determine the number of neutron sources 5 assembled in the active area of the component, and according to the neutron yield of Cf-252 self-fission, this embodiment adopts a mass of 43.3×10 -6 The neutron source 4 of g, wherein the neutron emission rate of the neutron source 4 is 1.0×10 8 n / s, the compression pad 3 is made of alumina gasket, the support pad 5 is made of alumina gasket, and then the upper end plug 2, the compression pad 3, and the neutron source are sequentially assembled 4. Support the cushion block 5, and fix the neutron source 4 in the active area in the cladding tube 7, and assemble the lower end plug 6 after assembly.

[0023] The upper and lower end plugs 2, 6 of the primary neutron source part are welded and sealed on the cladding tube 7: first, the upper and lower end plugs 2, 6 of the sealed part are welded by argon arc welding. Then, from the helium inlet of the lower end plug 6, 1.5 MPa h...

Embodiment 2

[0026] This embodiment is the same as Embodiment 1, the difference is that this embodiment adopts a mass of 43.3×10 -6 The neutron source 4 of g, wherein the neutron emission rate of the neutron source 4 is 1.0×10 8 n / s, then, sequentially assemble the upper end plug 2, the compression spacer 3, the neutron source 4, the support spacer 5, and fix the neutron source 4 in the active area at the center position of the cladding tube 7, after assembly , Assemble the lower end plug 6. Fill the cladding tube 7 with 1.5MPa helium gas from the helium gas inlet of the lower end plug 6 .

Embodiment 3

[0028] This embodiment is the same as Embodiment 1, the difference is that this embodiment adopts a mass of 129.9×10 -6 The neutron source 4 of g, wherein the neutron emission rate of the neutron source 4 is 3.0×10 8 n / s, the compression cushion block 3 is a compression cushion block made of stainless steel, and the support cushion block 5 is a support cushion block made of stainless steel. Assemble the upper end plug 2, the compression block 3, the neutron source 4, the support block 5 in sequence, and assemble the lower end plug 6. From the helium inlet of the lower end plug 6, fill the cladding tube 7 with 1.2MPa helium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com