Trimmer and method for regulating resistance value of resistance component as well as electronic device

A technology of resistance value and components, applied in the direction of non-adjustable metal resistors, resistors, resistance manufacturing, etc., can solve the problems of increasing the high-precision requirements of resistance value trimming, high resistance processing costs, and affecting the accuracy of resistance value trimming, etc. Achieve the effect of increasing commercial competitiveness, reducing purchase cost, high precision and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

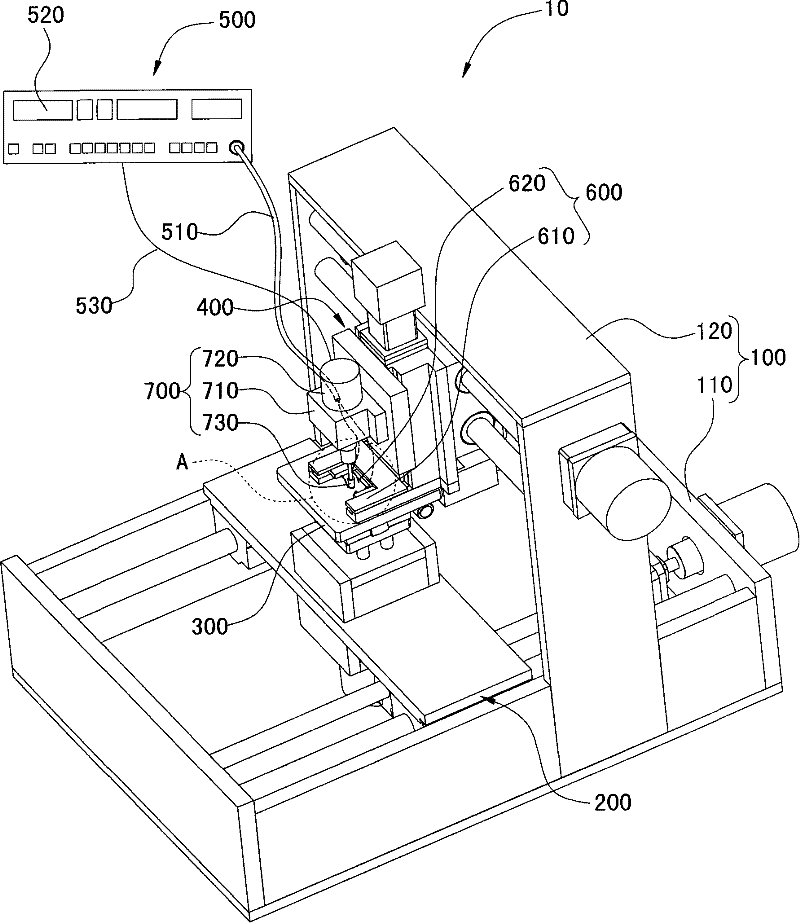

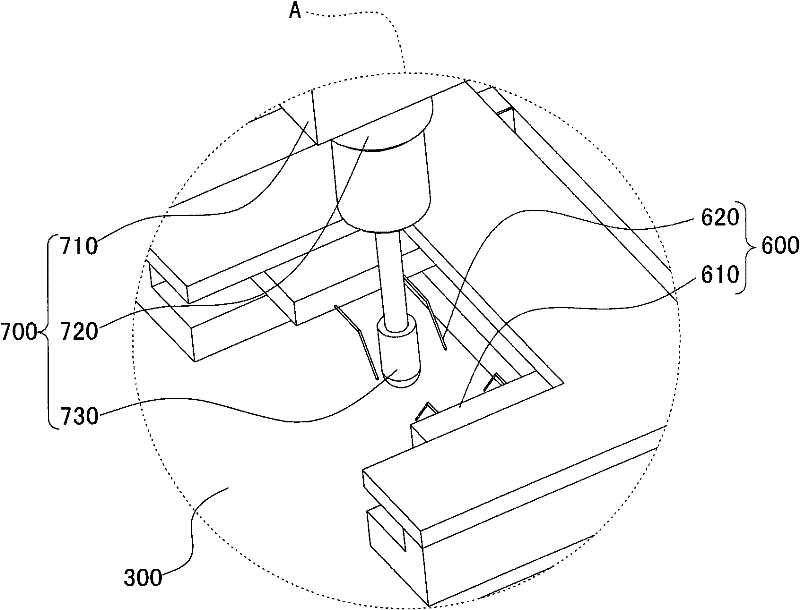

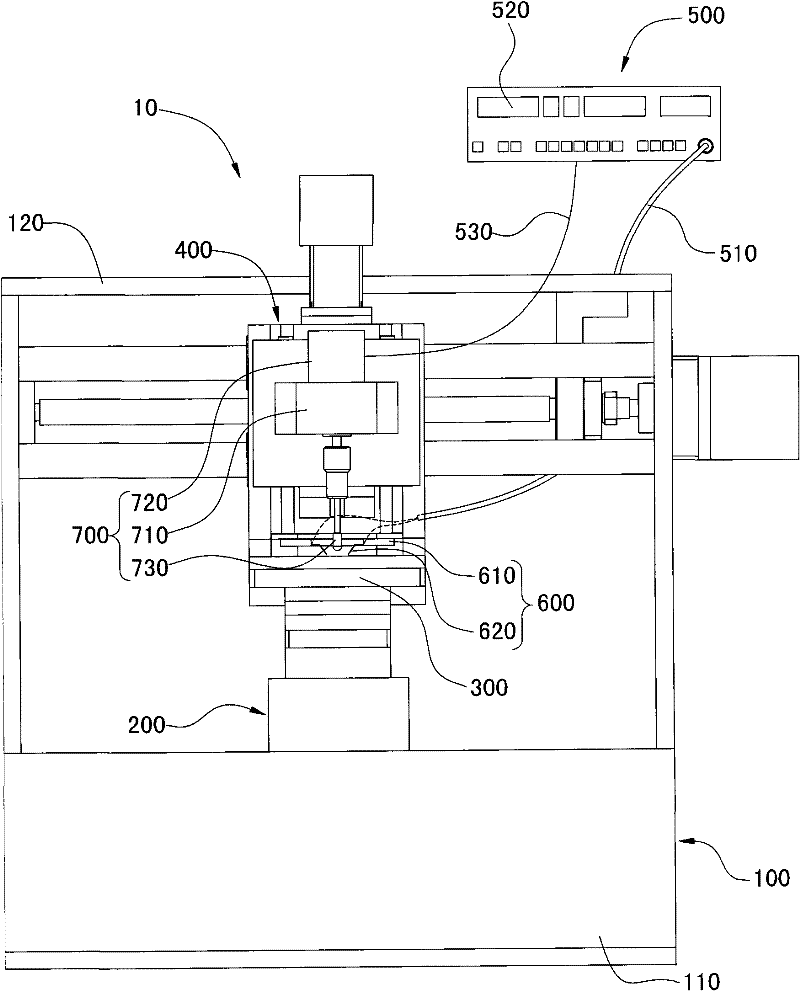

[0072] A resistance repairing machine for adjusting the resistance value of resistance components of the present invention, please refer to Figure 1 to Figure 4 as shown, figure 1 It is the three-dimensional combination diagram of the resistance repairing machine, figure 2 for figure 1 The magnified view of part A in the image 3 for figure 1 main view of Figure 4 for figure 1 right view of . In one embodiment, the resistance repairing machine 10 includes a machine body 100 , a guiding mechanism 200 , a platform 300 , a guiding mechanism 400 , a processor 500 , a detection device 600 and a trimming device 700 .

[0073] The machine body 100 is used for installing or placing various components in the block repairing machine 10 . The machine body 100 includes a seat 110 and a bracket 120 vertically fixedly arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com