Rectifier module with cooled busbar

A technology for power converters and busbar systems, which is applied to output power conversion devices, conversion of AC power input to DC power output, cooling/ventilation/heating transformation, etc., and can solve the problem of increasing busbar system, increasing weight, and increasing costs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

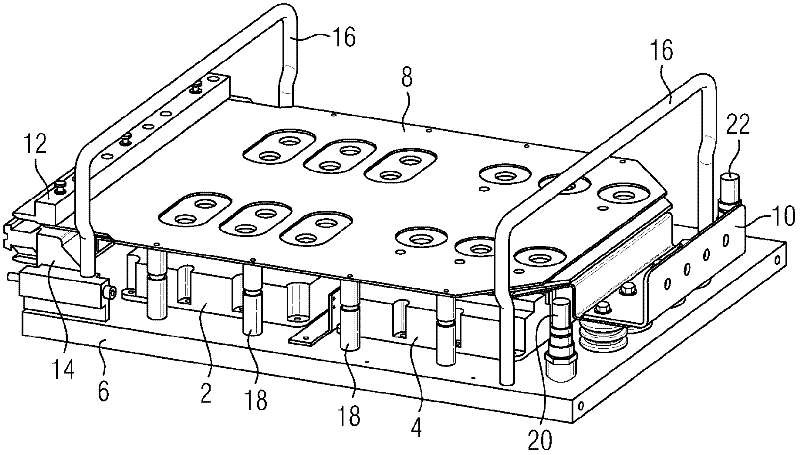

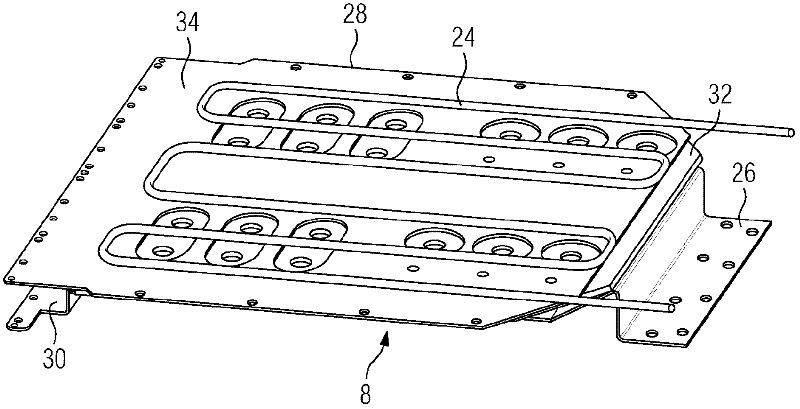

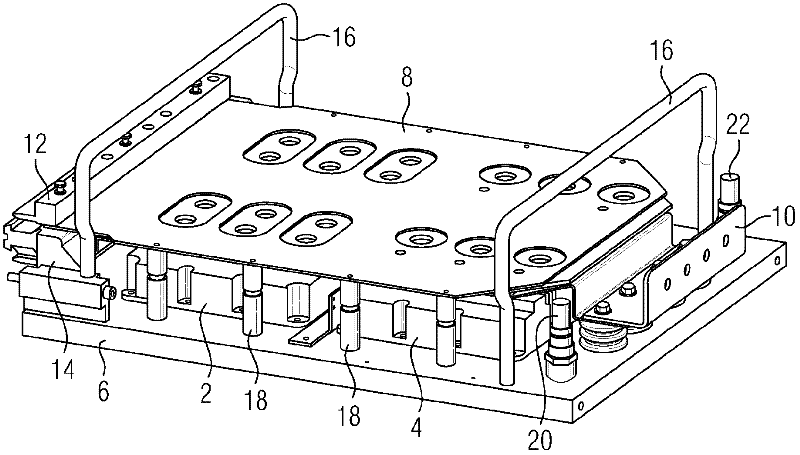

[0017] figure 1 It is a perspective view of a commercially available power converter module, wherein 2 and 4 each represent a power semiconductor module, especially a power semiconductor module that can be turned off, such as an insulated gate bipolar transistor (IGBT), and 6 represents a liquid-cooled radiator , 8 represents the busbar system, 10 represents the load connection terminal, 12 and 14 represent a DC voltage connection terminal, 16 represents the bow-shaped element, and 18 represents the support element. In addition, a coolant inlet 20 and a coolant outlet 22 are shown.

[0018] The two power semiconductor modules 2 and 4 are mechanically fixed together with the liquid-cooled radiator 6 in a detachable manner. The busbar system 8 may have two busbars, such as a positive busbar plus a load busbar, or a load busbar plus a negative pole busbar, or three busbars, such as a positive pole busbar, a load busbar plus a negative pole busbar. The number of bus bars of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com