Puncture trocar

A puncture needle and trocar technology, applied in the directions of puncture needles, trocars, needles, etc., can solve the problems of inaccurate orientation of the puncture needle and increase the success rate of puncture, so as to reduce the damage, reduce the number of punctures, and increase the success rate. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

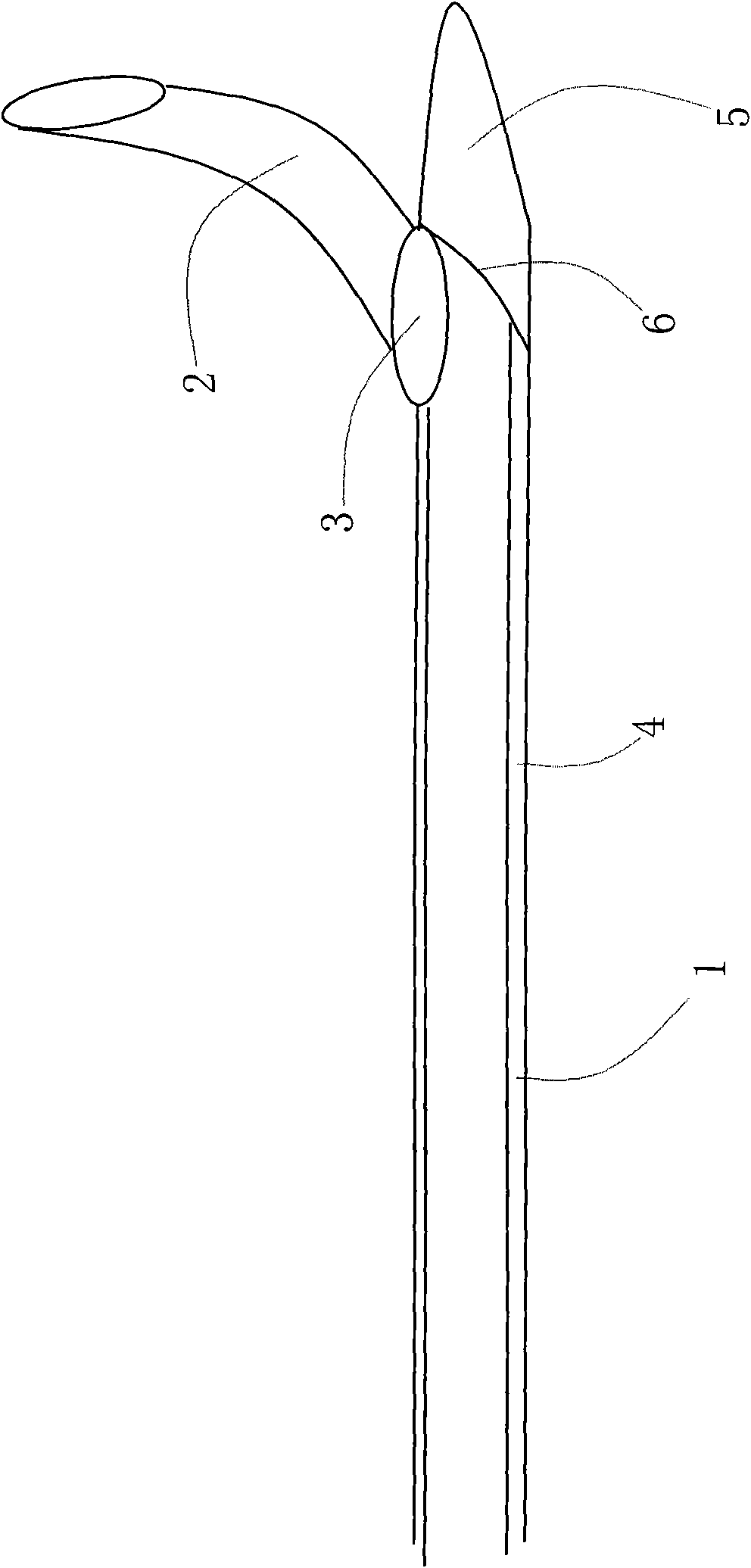

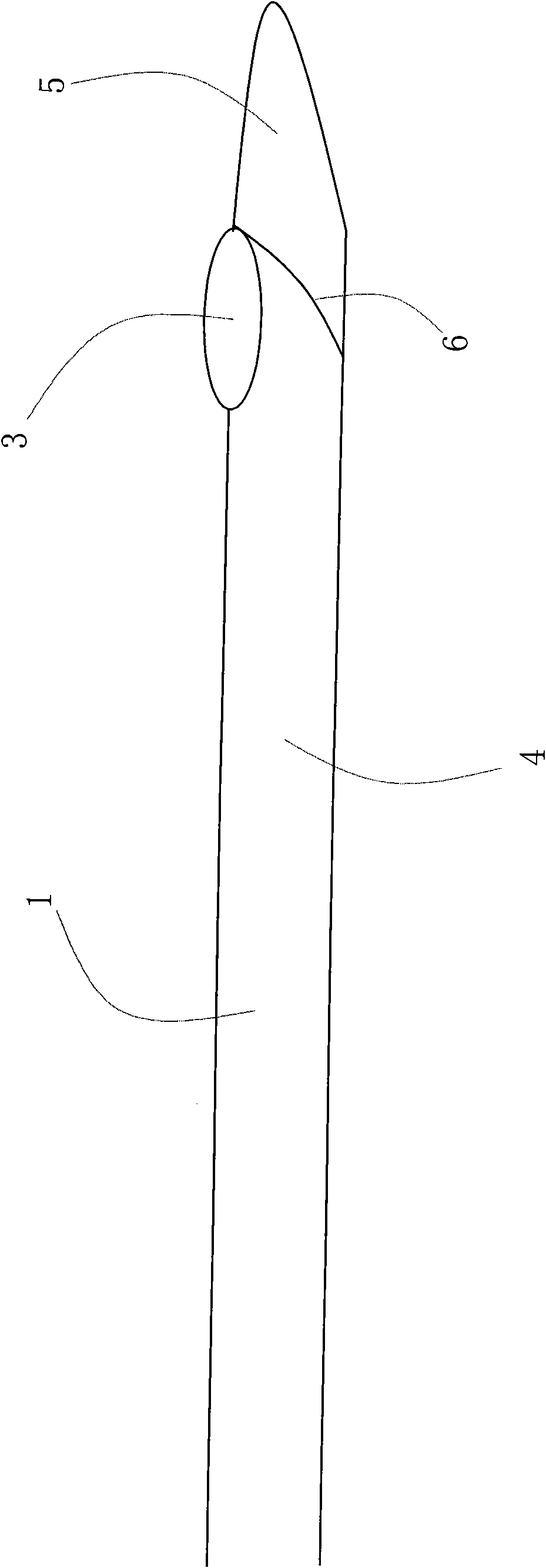

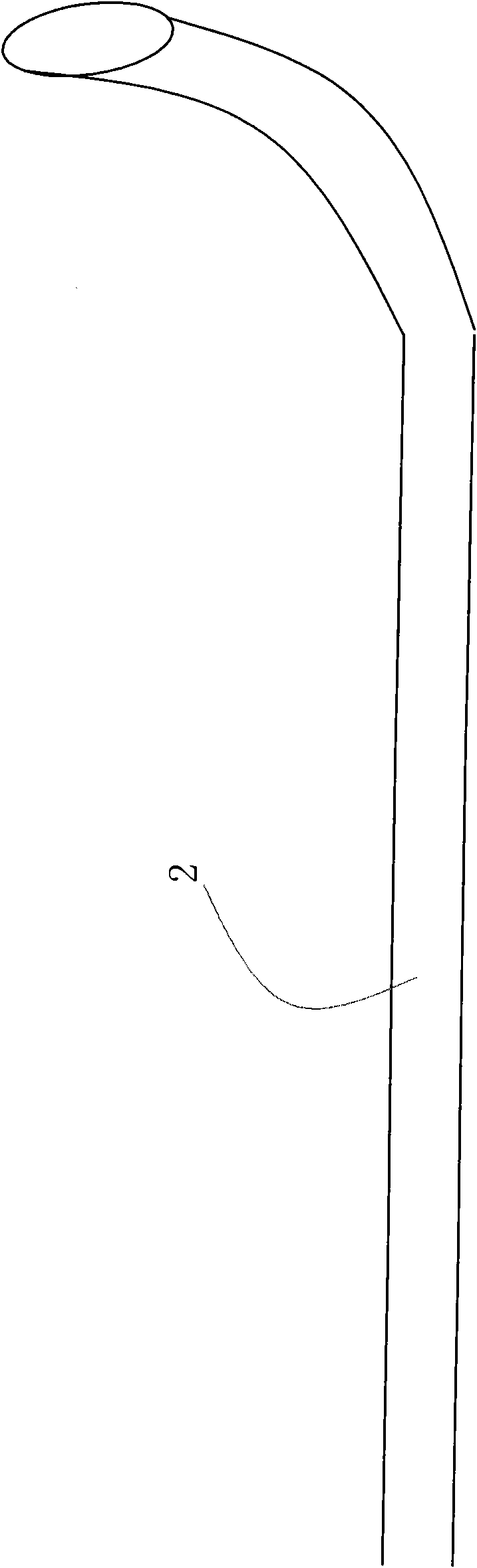

[0017] like figure 1 The puncture trocar includes an outer sleeve 1 with a needle point and a series of needle cores 2 with different radians, each needle core 2 can be hidden in the inner cavity of the outer sleeve 1, and the series of needles with different radians Core 2 is used for adapting to different turning angles and is 5~30G, and the arc of this arc-shaped needle core 2 is arranged on the front end of needle core 2 (such as image 3 As shown), the arc-shaped needle core 2 is made of high-elastic material, and the high-elastic material is carbon fiber, which has high specific strength, high specific modulus, high temperature resistance, corrosion resistance, heat transfer and small coefficient of thermal expansion, etc. series of excellent performance, there is a side hole 3 matching with the needle core 2 on the side of the outer sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com