Lost foam automatic line

An automatic line, lost foam technology, applied in casting molding equipment, molds, cores, etc., can solve the problems of idle sand box congestion and idleness, production line standstill and waiting, waste of resources, etc., to reduce production and operation costs, effectively utilize The effect of having resources and reducing site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

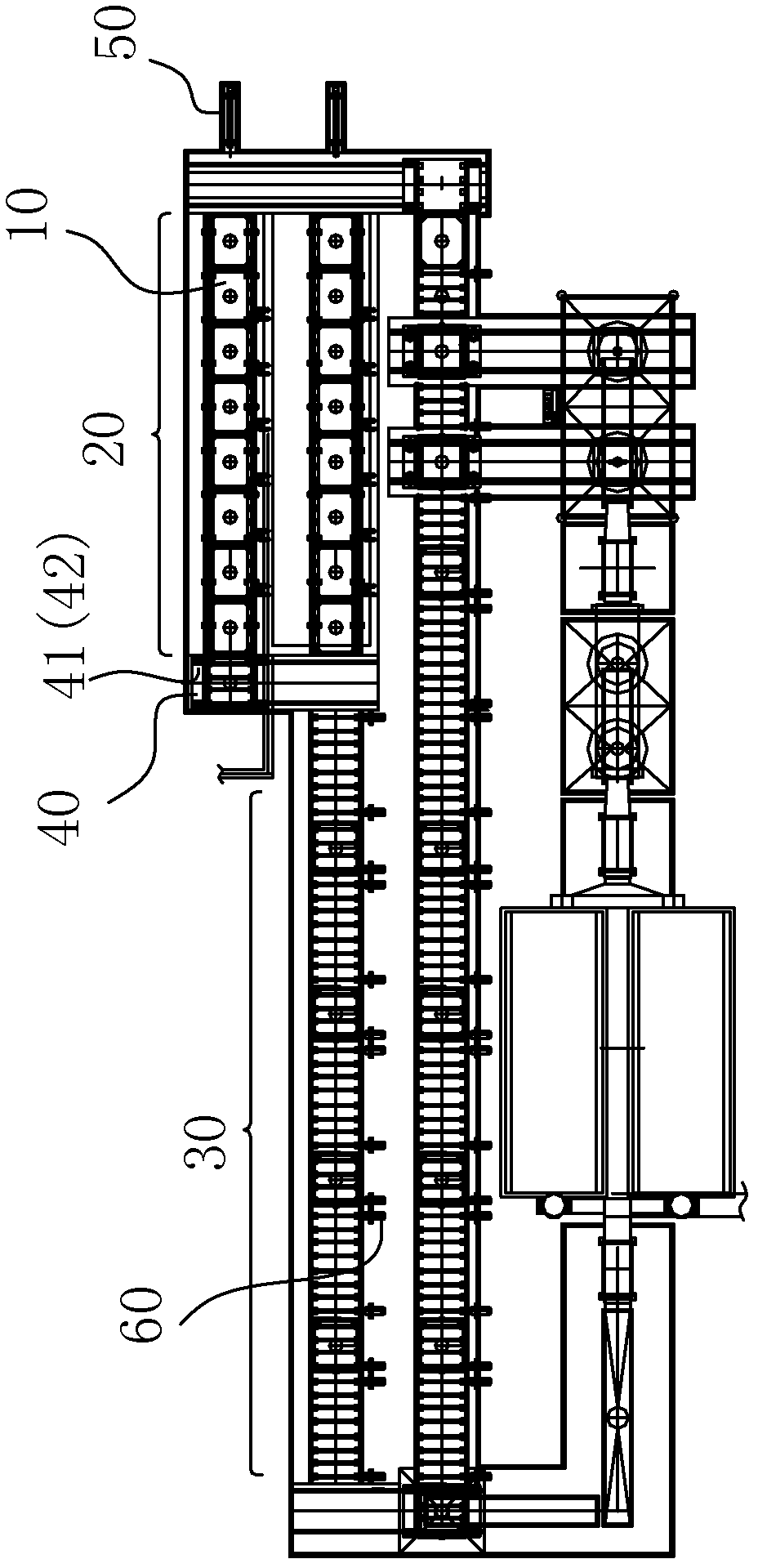

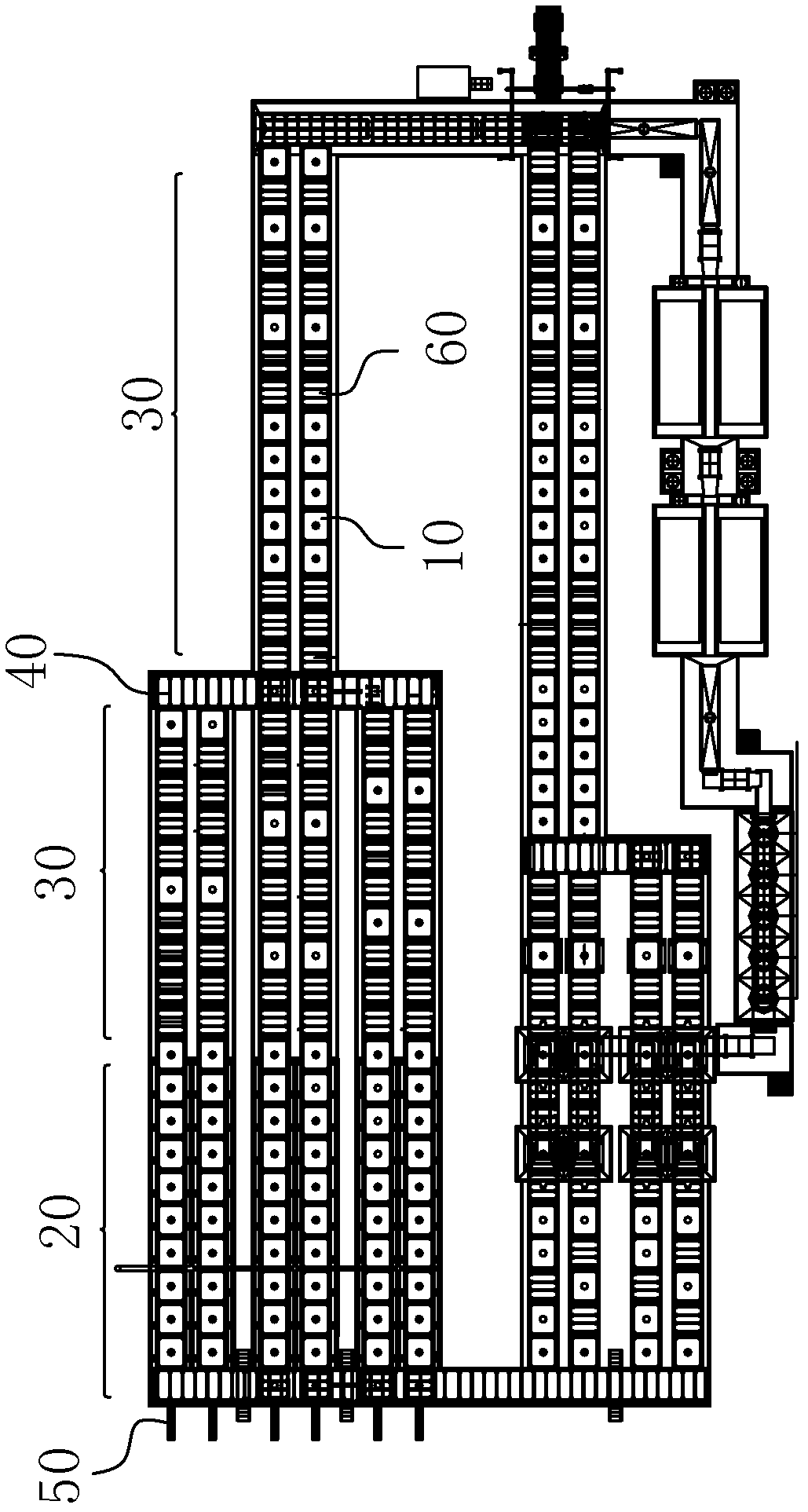

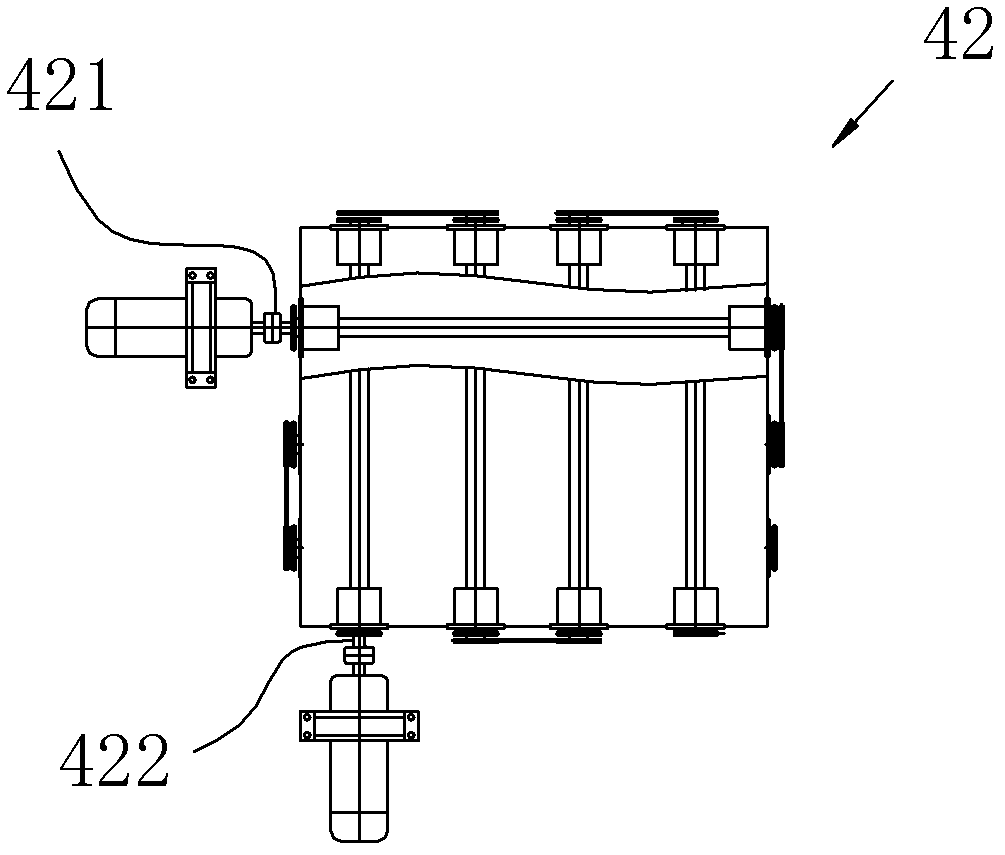

[0008] An automatic lost foam line, which is divided into a plurality of process sections for conveying the sand box 10 and realizing its corresponding process. The process sections are sequentially connected and provided with a power mechanism for driving the sand box 10 to move along its conveying direction. The process section includes a pouring section 20 and a heat preservation section 30 connected thereto. The pouring section 20 is composed of at least two sets of pouring lines, and multiple sets of pouring lines of the pouring section 20 extend to the subsequent process section. And finally close together as a group, the close-up of the multiple groups of pouring lines is located in the insulation section 30 or the junction of the insulation section 30 and the pouring section 20, such as Figure 1-2 shown.

[0009] As a further preferred version of the present invention: as Figure 1-2 As shown, the pouring lines of the pouring section 20 are arranged side by side in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com