Fixture disc

A fixture plate and mold technology, used in the manufacture of tools, grinders, machine tools with surface polishing, etc., can solve the problems of loss of polishing meaning, mold collision, low work efficiency, etc., to improve polishing quality, protect molds, and improve polishing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

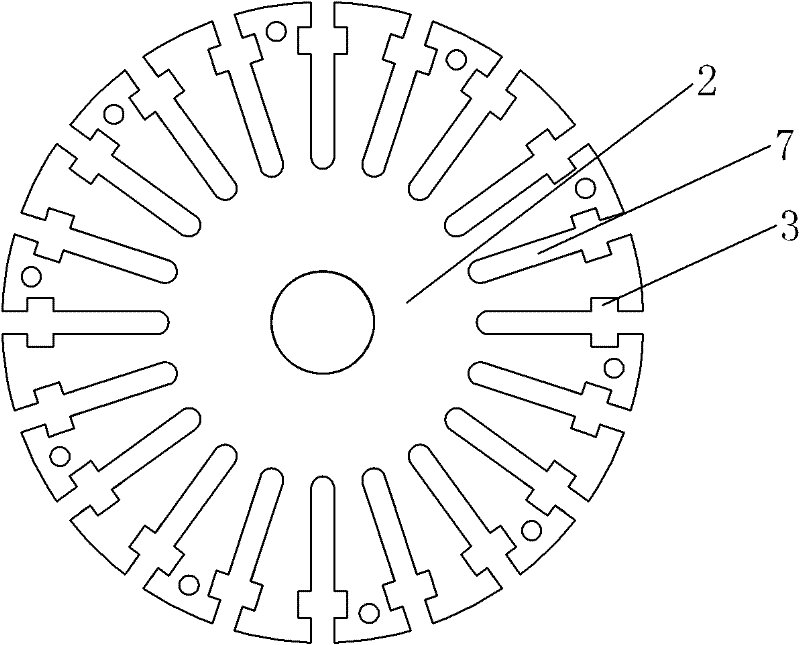

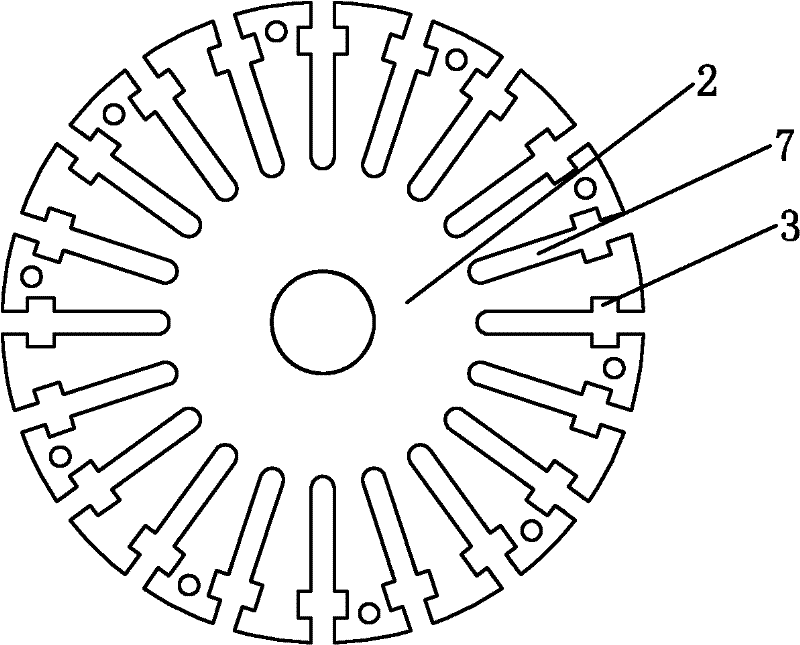

[0016] Embodiment: a kind of fixture disk, as figure 1 As shown, the fixture disk 2 is circular, and a plurality of mold slots 3 are uniformly distributed along the circumferential direction on the fixture disk 2; on the fixture disk 2, there are many long grooves 7 radiating outward along the center of the fixture disk, The long groove 7 crosses and communicates with the mold slot 3 , and the width of the long groove 7 is smaller than the width of the mold slot 3 .

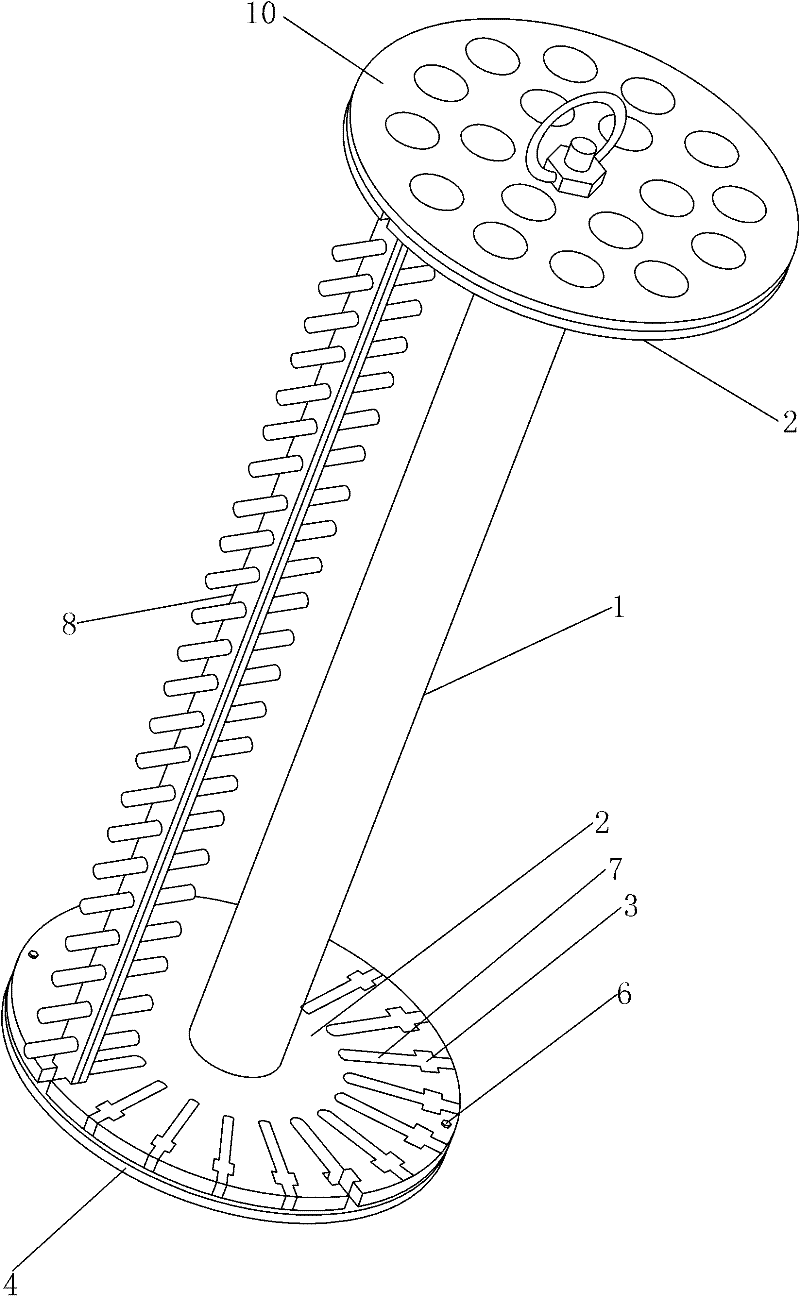

[0017] The assembled fixture of the fixture plate is as follows figure 2 As shown, the fixture includes a fixture spindle 1, and a fixture disc 2 is respectively arranged at the upper and lower ends of the fixture spindle 1. In order to limit the position of the two fixture discs respectively, a support disc 4 is provided on the fixture disc at the lower end of the fixture main shaft 1, and the support disc 4 is connected with the clamp disc at the lower end of the clamp main shaft 1 through bolts 6, and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com