Device for detaching and assembling bearing

A technology of bearings and central shafts, which is applied in the field of devices for deep hole disassembly and installation of bearings in heavy equipment, can solve the problems of labor-intensive headlights, long operation cycle, and high operation cost, and achieve low labor intensity, low cost, and convenient implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

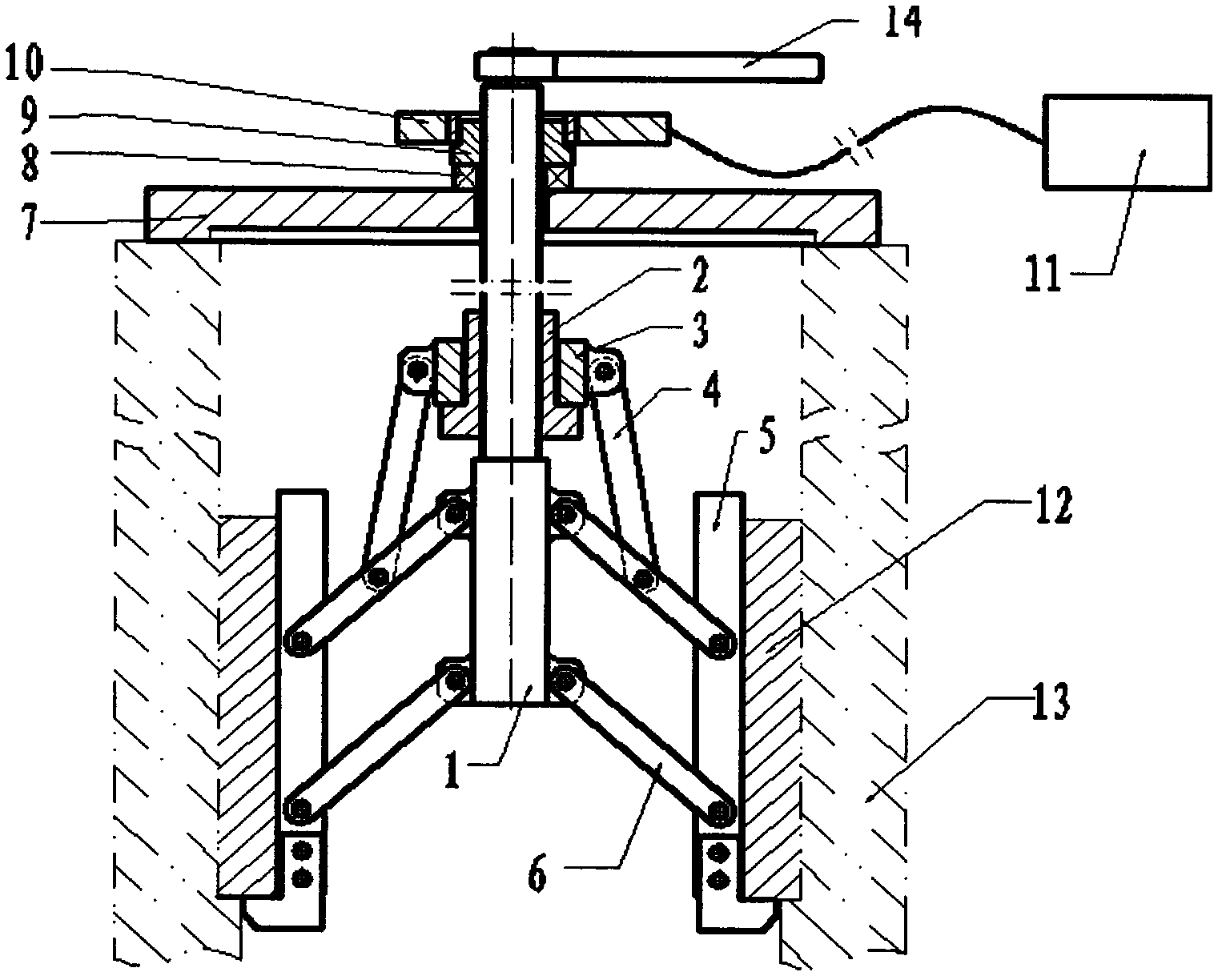

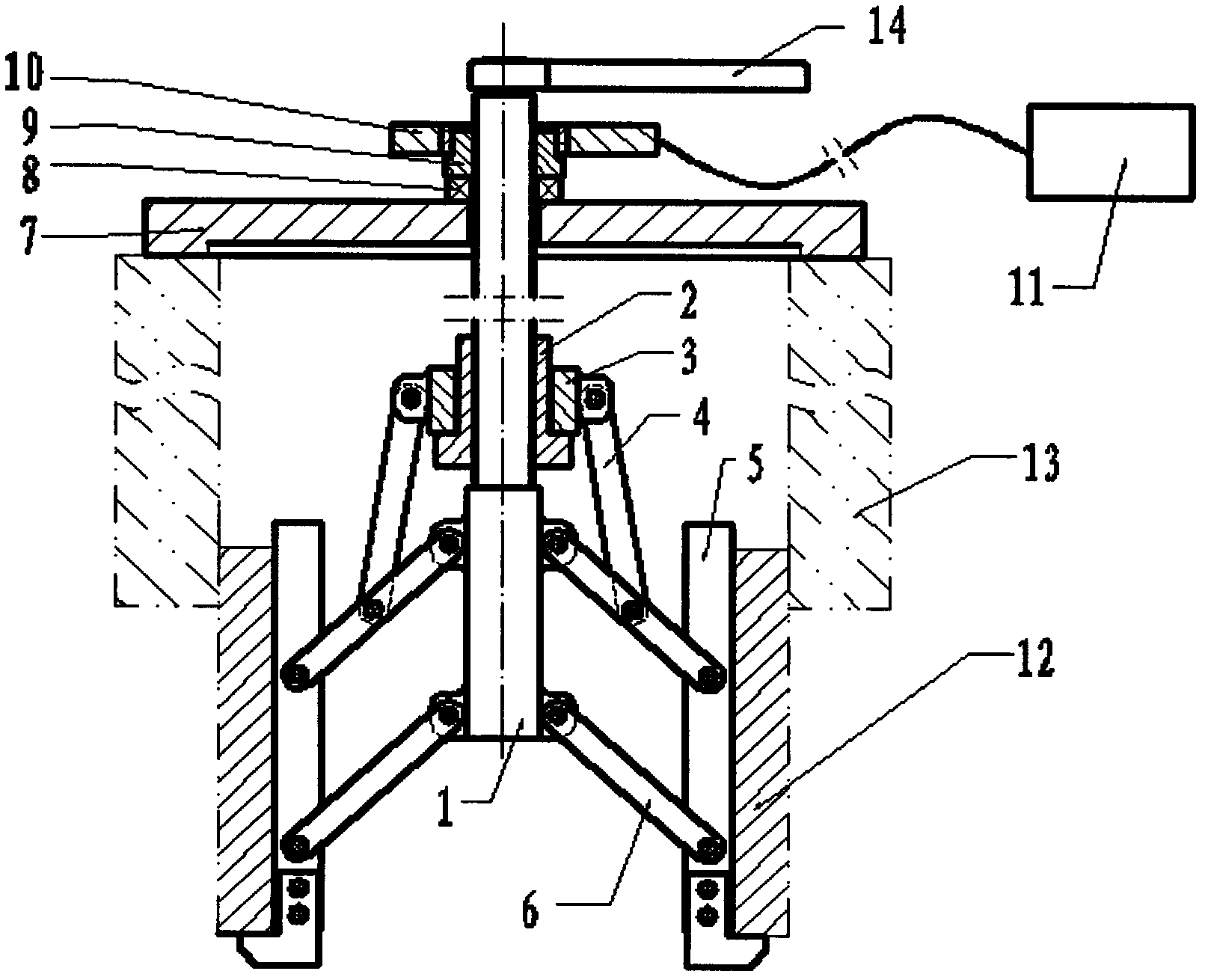

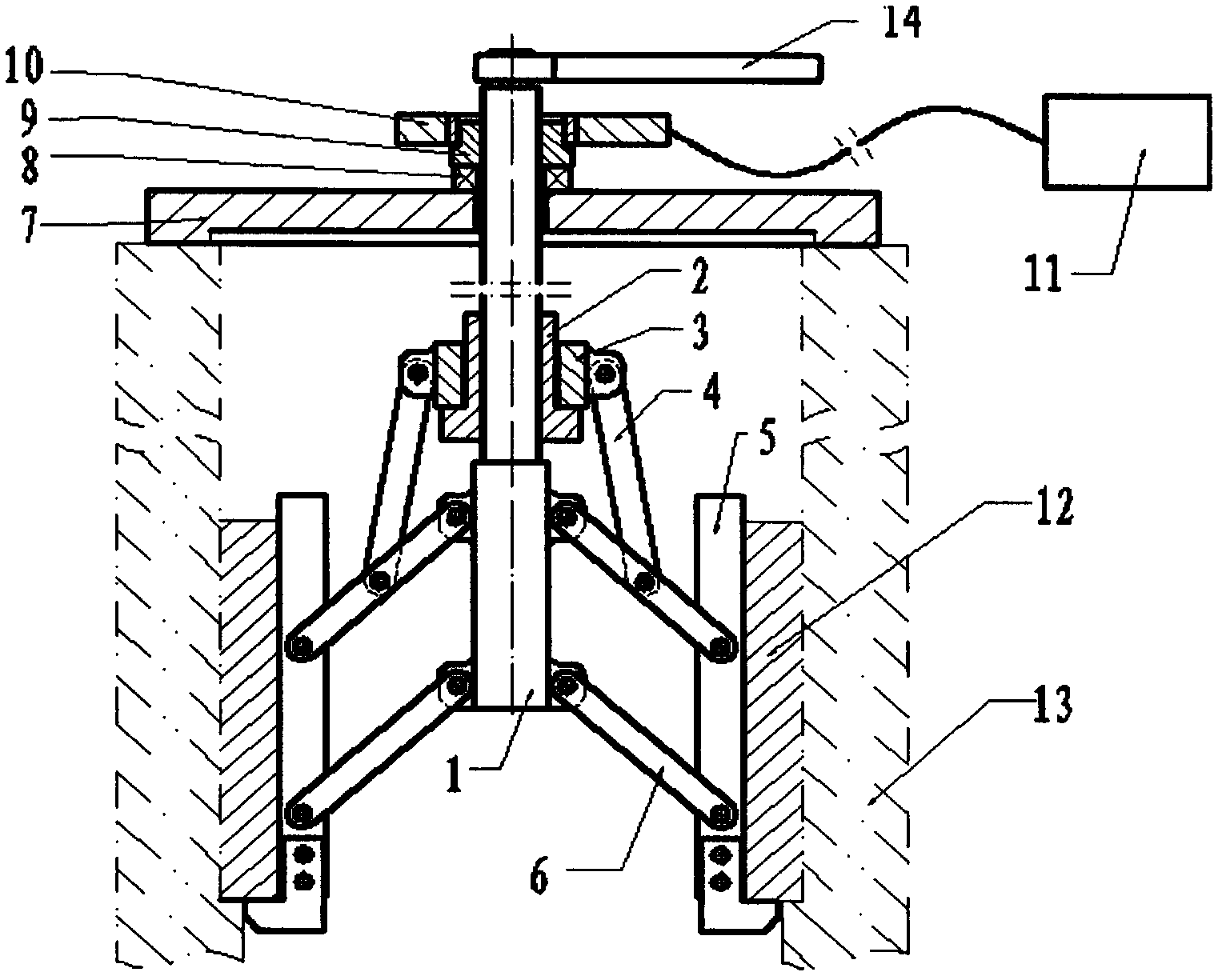

[0024] The present invention will be described below through a specific embodiment in conjunction with the accompanying drawings.

[0025] refer to figure 1 , figure 2 , first place the entire device directly above the sliding bearing hole to be disassembled, rotate the nut sleeve 2 to move it downward, adjust the pull rod 4 to reduce the distance between the draw hook and the central shaft frame 1, and then extend the draw hook 5 into the inner hole of the slide bearing 12 . By adjusting the nut sleeve 2, driving the pull rod connecting sleeve 3, adjusting the pull rod 4, and the parallel connecting rod 6, the pull hook 5 is driven to adjust the opening degree, so that the pull hook 5 put into the hole fits the inner wall and the lower end surface of the sliding bearing 12. After the support plate 7, thrust self-aligning roller bearing 8, hexagonal flange surface nut 9, hydraulic wrench 10, hydraulic station 11, etc. are installed and fixed, start the hydraulic wrench. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com