Method and device for cleaning gas in blowing machines

A technology of blow molding machine and gas, which is applied in the field of gas in the blow molding machine, and can solve the problems of polluting the blow molding mold and the risk of microbial impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

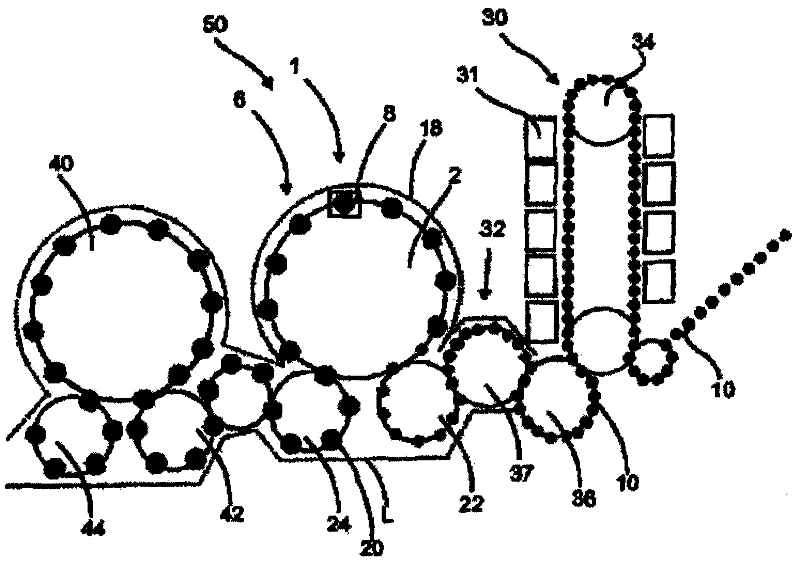

[0103] figure 1 is a schematic diagram of a prior art system for producing plastic containers. The system 50 has a heating device 30 in which the plastic pre-forms 10 are heated. At this point, the plastics material pre-forms 10 are conveyed past the heating device 30 by means of a conveying device 34 , here an endless chain, and heated by a plurality of heating elements 31 . The heating device 30 is followed by a transfer unit 36 which transfers the plastics material pre-forms 10 to a sterilization device 32 . In this case, the sterilizing device 32 also has a transfer wheel 37 , on which a plurality of sterilizing elements can be arranged or can even be arranged in a fixed manner. In this area, for example, hydrogen peroxide gas can be used, or, as mentioned above, sterilization c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com