Blending edible vinegar and preparation method thereof

A technology for vinegar and summer vinegar, which is applied in the field of vinegar, can solve the problems of single variety of vinegar, weak typical flavor, and insufficient vinegar aroma, and achieves rich aroma components, improved quality instability, and soft and sweet taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 65Kg of raw vinegar, 10Kg of summer vinegar, 15Kg of five-year-aged vinegar and 10Kg of whole-smoked fermented grain vinegar, mix them evenly, fry the obtained mixed vinegar at 80°C for 2.5 hours, sterilize and fill to make mixed vinegar .

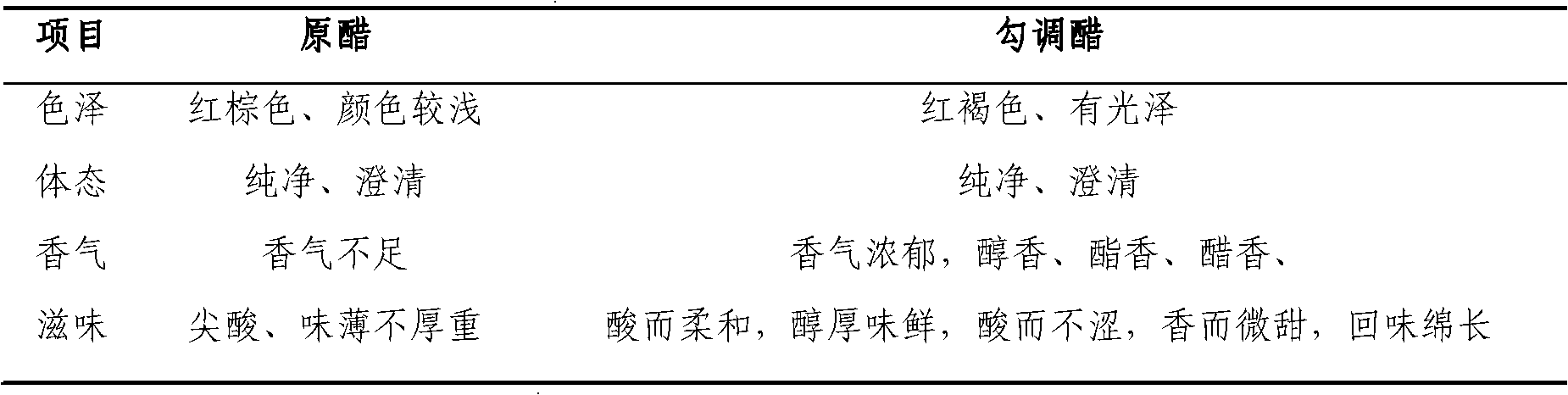

[0024] The comparison of sensory indicators before and after blending of raw vinegar is as follows:

[0025]

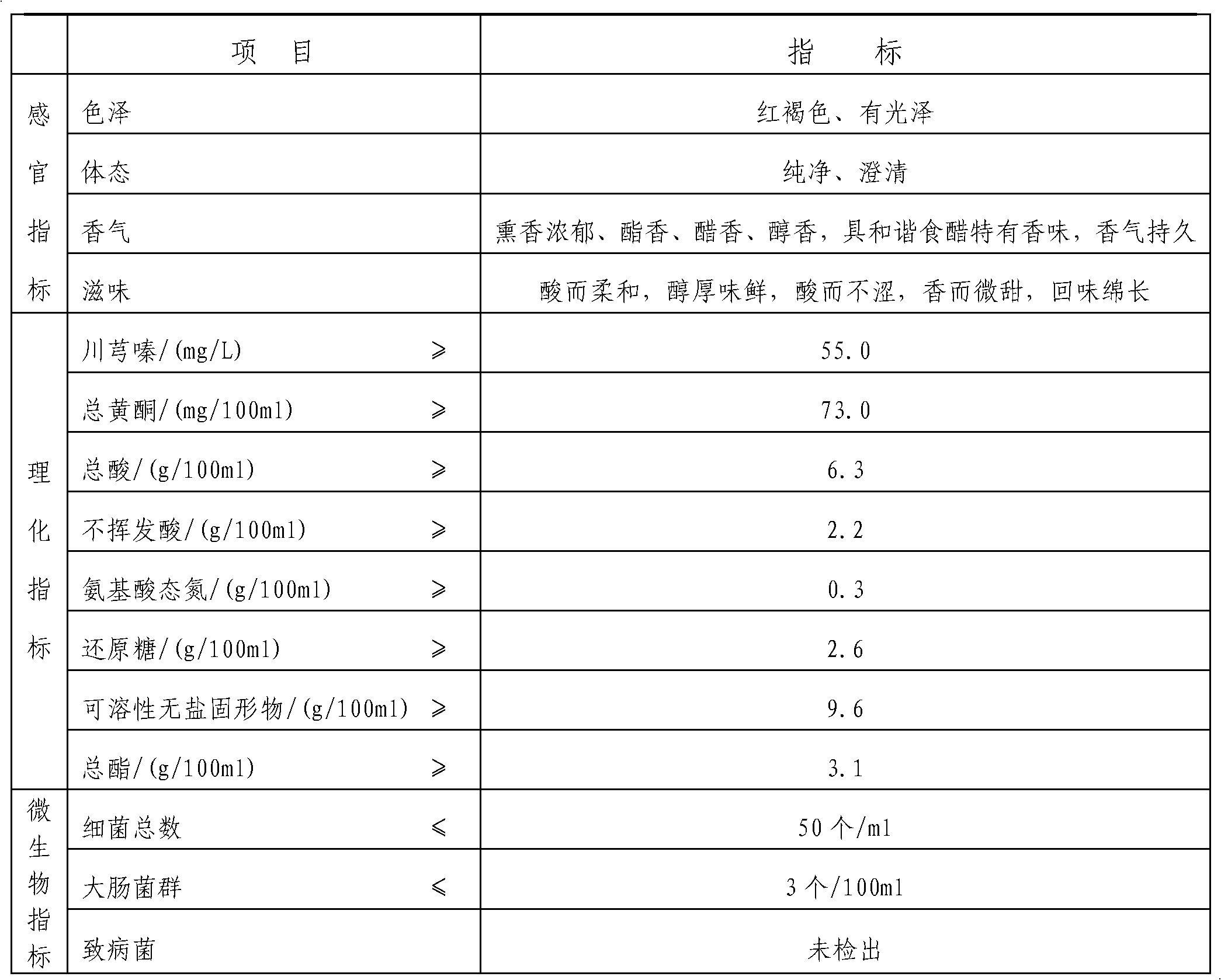

[0026] The physical and chemical indicators of raw vinegar before and after blending are compared as follows:

[0027]

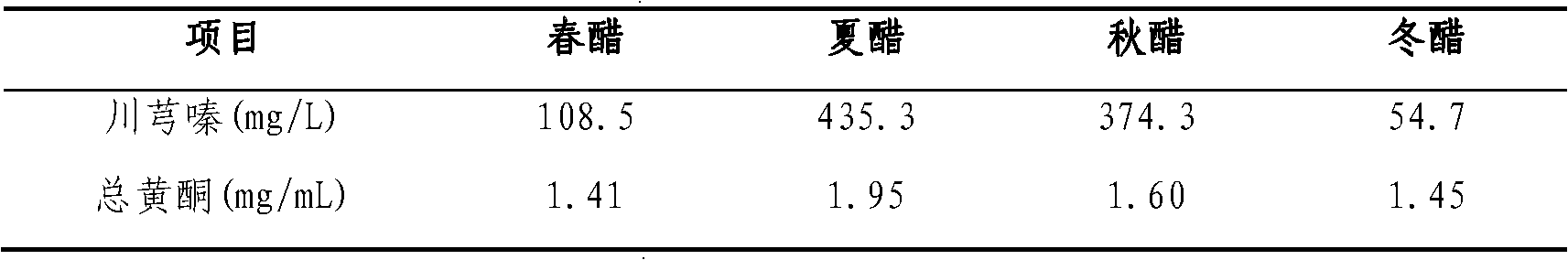

[0028] The comparison of key control points before and after blending of raw vinegar is as follows:

[0029]

Embodiment 2

[0031] Take 70Kg of raw vinegar, 13Kg of summer vinegar, 10Kg of five-year-aged vinegar and 7Kg of whole-smoked fermented grain vinegar, mix them evenly, fry the obtained mixed vinegar at 90°C for 2 hours, sterilize and fill to make mixed vinegar .

Embodiment 3

[0033] Take 60Kg of raw vinegar, 15Kg of summer vinegar, 5Kg of five-year-aged vinegar and 20Kg of whole-smoked fermented grain vinegar, mix them evenly, fry the obtained mixed vinegar at 80°C for 2.5 hours, sterilize and fill it to make mixed vinegar .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com