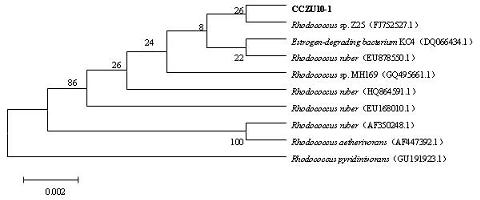

Rhodococcussp.CCZU10-1 and method for synthesizing benzoyl formic acid through nitrile hydrolysis by using same

A technology of acetophenone acid and Rhodococcus, which is applied in the field of microorganisms and achieves the effects of no by-products, high conversion rate, simple process route and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Rhodococcus Rhodococcus sp. CCZU10-1 grows cells and catalyzes the hydrolysis of benzoylcarbonitrile to produce acetophenone

[0033]Prepare seed medium (glucose 5 g, peptone 5 g, yeast extract 5 g, KH 2 PO 4 1 g, NaCl 0.5 g, MgSO 4 0.1 g, 1000 mL of water, pH 6.0), fill 200 mL of seed medium in a 1 L shake flask, and cultivate the seed liquid. Then prepare the fermentation medium (glucose 5 g, peptone 5 g, yeast extract 5 g, KH 2 PO 4 1 g, NaCl 0.5 g, MgSO 4 0.1 g, FeSO 4 . 7H 2 O 0.01 g, inducer caprolactam 0.01 g, water 1000 mL, pH 6.0). Put 2.5 L of fermentation medium in a 5 L fermenter, add 1% seed liquid after disinfection, ventilation rate 1:0.1 (v / v / m), stirring speed 200 rpm, temperature 20 °C, and carry out fermentation culture 15 h, add 100 mM benzoylformonitrile, sample HPLC analysis at different times, when the analysis yield of acetophenone acid is 96%, continue to add 100 mM benzoylformonitrile solution neutralized by sodium hydroxide, Wh...

Embodiment 2

[0035] Rhodococcus Rhodococcus Sp. CCZU10-1 quiescent cells catalyze the production of acetophenone from benzoylcarbonitrile

[0036] Prepare seed medium (glucose 15 g, peptone 20 g, yeast extract 20 g, KH 2 PO 4 5 g, NaCl 2.5 g, MgSO 4 2.5 g, water 1000 mL, pH 9.0), fill 200 mL seed medium in a 1 L shake flask, and cultivate the seed liquid. Then prepare the fermentation medium (glucose 15 g, peptone 20 g, yeast extract 20 g, KH 2 PO 4 5 g, NaCl 2.5 g, MgSO 4 2.5 g, FeSO 4 . 7H 2 O 0.1 g, inducer caprolactam 10 g, water 1000 mL, pH 9.0). Add an appropriate amount of fermentation medium accounting for 3.5L of the volume of the fermentation tank into the 5 L fermenter, and the inoculation amount accounts for 10% of the volume of the fermentation medium. After disinfection, inoculate into the 5 L fermenter, and the ventilation rate is 1:1:1 (v / v / m), the stirring speed was 450 rpm, the temperature was 40 °C, and the time was 120 h, centrifuged and washed to obtain...

Embodiment 3

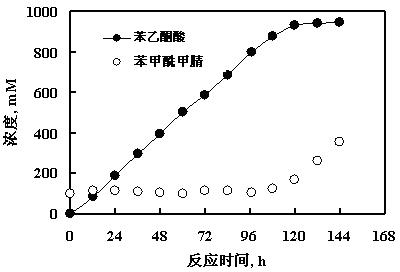

[0038] fed-batch utilization of Rhodococcus Rhodococcus Sp. CCZU10-1 quiescent cells catalyze the production of acetophenone from benzoylcarbonitrile

[0039] Weigh 10 g of resting cells with a wet weight obtained from the culture in Example 2, suspend the cells in 1000 mL pH 8.0 potassium phosphate buffer solution-toluene (90%:10%, volume ratio), add benzoylcarbonitrile respectively, The final concentration was 100 mM, and the reaction was shaken on a constant temperature shaker at 40 °C and 160 rpm. After 12 h of reaction, 100 mM substrate benzoylcarbonitrile was fed in batches for the synthesis of acetophenone acid. figure 2 It showed that the substrate was fed 10 times (100 mM each time), and the cumulative concentration of acetophenone was 932 mM after 120 h of reaction. During the hydrolysis of benzoylcarbonitrile, no generation of benzoylformamide was found.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap