Construction installation method for fast-easy setback grid of bottom plate construction joint

An installation method and a technology of construction joints, which are applied in the field of construction and installation of fast and easy closing nets, can solve problems such as different installation methods, and achieve the effects of low overall cost, fewer procedures, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

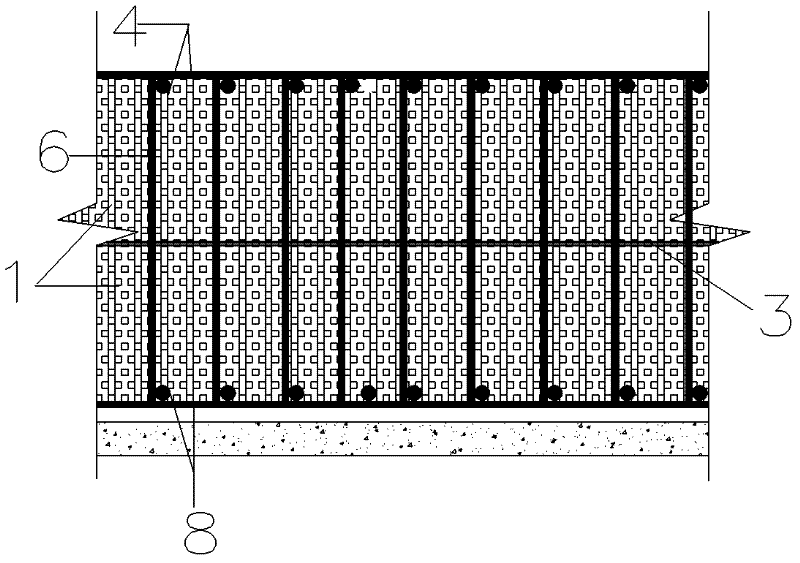

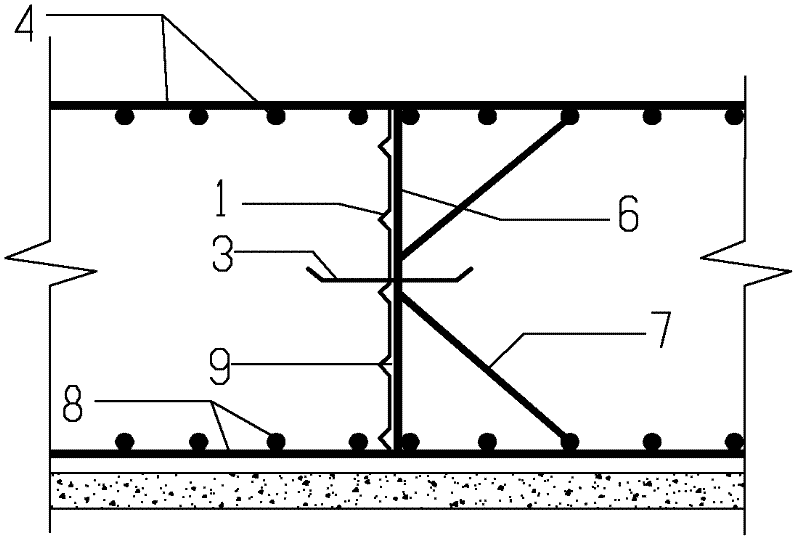

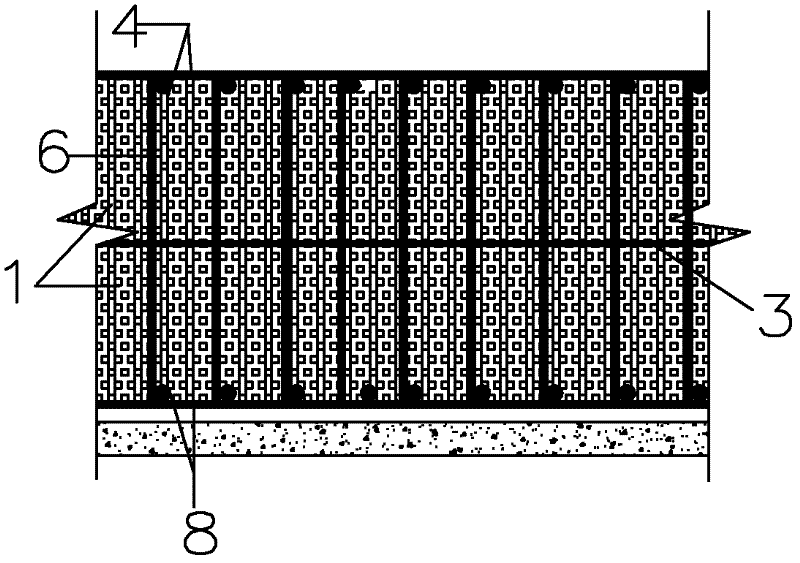

[0022] A quick and easy closing net construction and installation method for a construction joint of a bottom plate, comprising the following steps: (a) installing an upper-layer reinforcement mesh sheet and a lower-layer reinforcement mesh sheet respectively on the top surface and the bottom surface of the bottom floor construction joint; (b) installing the upper-layer reinforcement mesh Install water-proof steel plates between the upper steel mesh and the lower steel mesh; (c) Weld multiple upper vertical steel bars at intervals along the construction joint longitudinally between the upper steel mesh and the water-stop steel plate; A plurality of vertical steel bars of the lower layer are welded at intervals along the longitudinal direction of the construction joint; the vertical steel bars of the upper layer and the vertical steel bars of the lower layer are arranged at intervals of 150 mm. (d) Bind and connect the upper and lower parts of the fast and easy closing net to th...

Embodiment 2

[0025]A quick and easy closing net construction and installation method for a construction joint of a bottom plate, comprising the following steps: (a) installing an upper-layer reinforcement mesh sheet and a lower-layer reinforcement mesh sheet respectively on the top surface and the bottom surface of the bottom floor construction joint; (b) installing the upper-layer reinforcement mesh Install water-proof steel plates between the upper steel mesh and the lower steel mesh; (c) Weld multiple upper vertical steel bars at intervals along the construction joint longitudinally between the upper steel mesh and the water-stop steel plate; A plurality of vertical steel bars of the lower layer are welded at intervals along the longitudinal direction of the construction joint; the vertical steel bars of the upper layer and the vertical steel bars of the lower layer are arranged at an interval of 145mm. (d) Bind and connect the upper and lower parts of the fast and easy closing net to th...

Embodiment 3

[0028] A quick and easy closing net construction and installation method for a construction joint of a bottom plate, comprising the following steps: (a) installing an upper-layer reinforcement mesh sheet and a lower-layer reinforcement mesh sheet respectively on the top surface and the bottom surface of the bottom floor construction joint; (b) installing the upper-layer reinforcement mesh Install water-proof steel plates between the upper steel mesh and the lower steel mesh; (c) Weld multiple upper vertical steel bars at intervals along the construction joint longitudinally between the upper steel mesh and the water-stop steel plate; A plurality of vertical steel bars of the lower layer are welded at intervals along the longitudinal direction of the construction joint; the vertical steel bars of the upper layer and the vertical steel bars of the lower layer are arranged at an interval of 140mm. The connection between the upper steel mesh and the water-stop steel plate and betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com