Wall structure of SMC (Sheet Molding Compound) composite material

A composite material and wall structure technology, applied to walls, building components, building structures, etc., can solve problems such as prolonging the time for users or residents to take over houses, high material and labor costs, and increased sales prices, so as to shorten occupancy Effects of time, light weight, and avoidance of clean-up work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

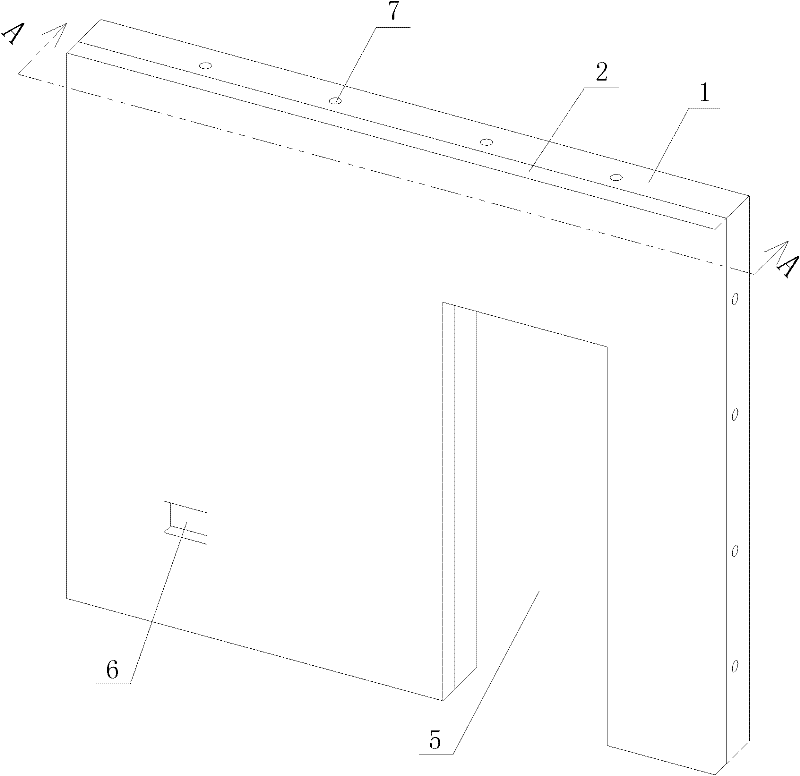

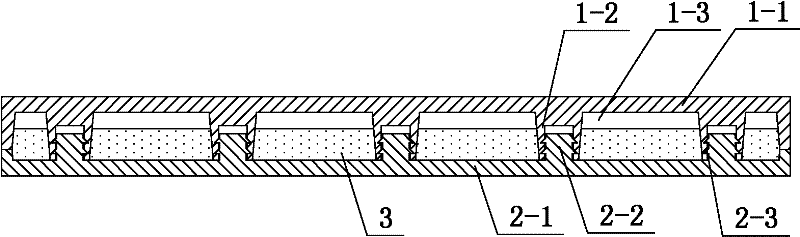

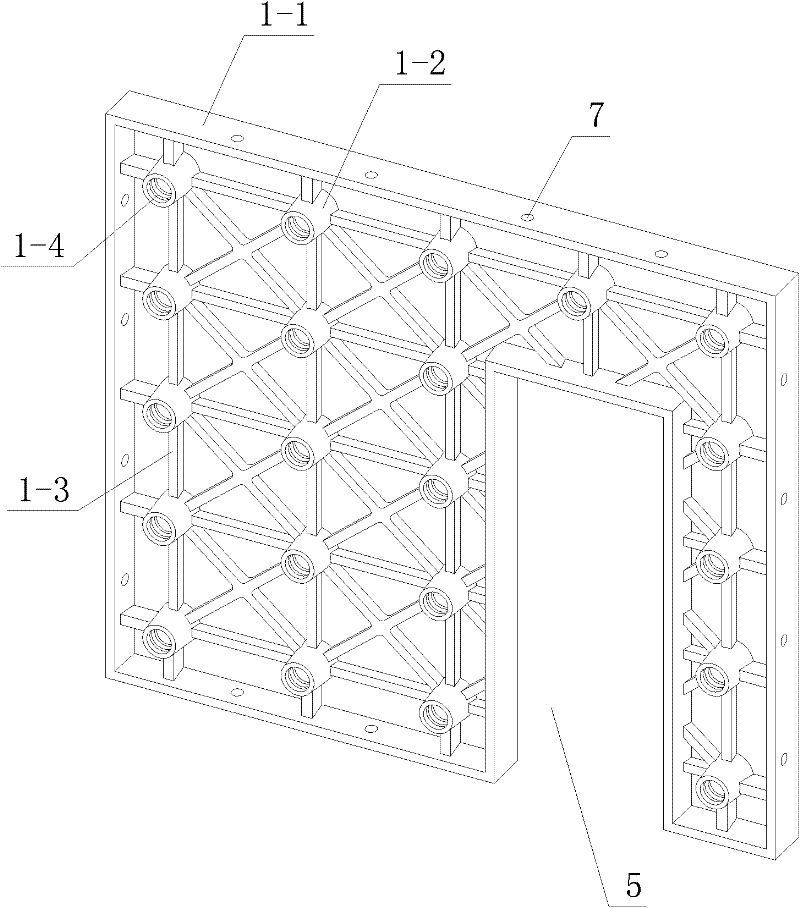

[0021] see Figure 1-4 , a wall structure of SMC composite materials, including a mother board 1 and a daughter board 2 molded by SMC composite materials, the daughter board is fastened on the mother board, and the mother board is fixed on the main frame of the building by expansion screws In the above, the motherboard includes a base 1-1 and a plurality of clamp sleeves 1-2 evenly distributed on the base, and the daughter board includes a base 2-1 and a plurality of clamps 2-2 evenly distributed on the base , the post is inserted into the post cover, the outer surface of the post is formed with a dovetail-shaped annular protrusion 2-3, and the inner hole of the post cover is provided with a Dovetail annular groove 1-4; the cavity between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com