Blade pump

A vane pump and vane technology, used in pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of easy wear of the tip of the vane, inability to popularize and apply, and high energy consumption of the vane pump, and achieve stable performance. Prominent substantive features and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

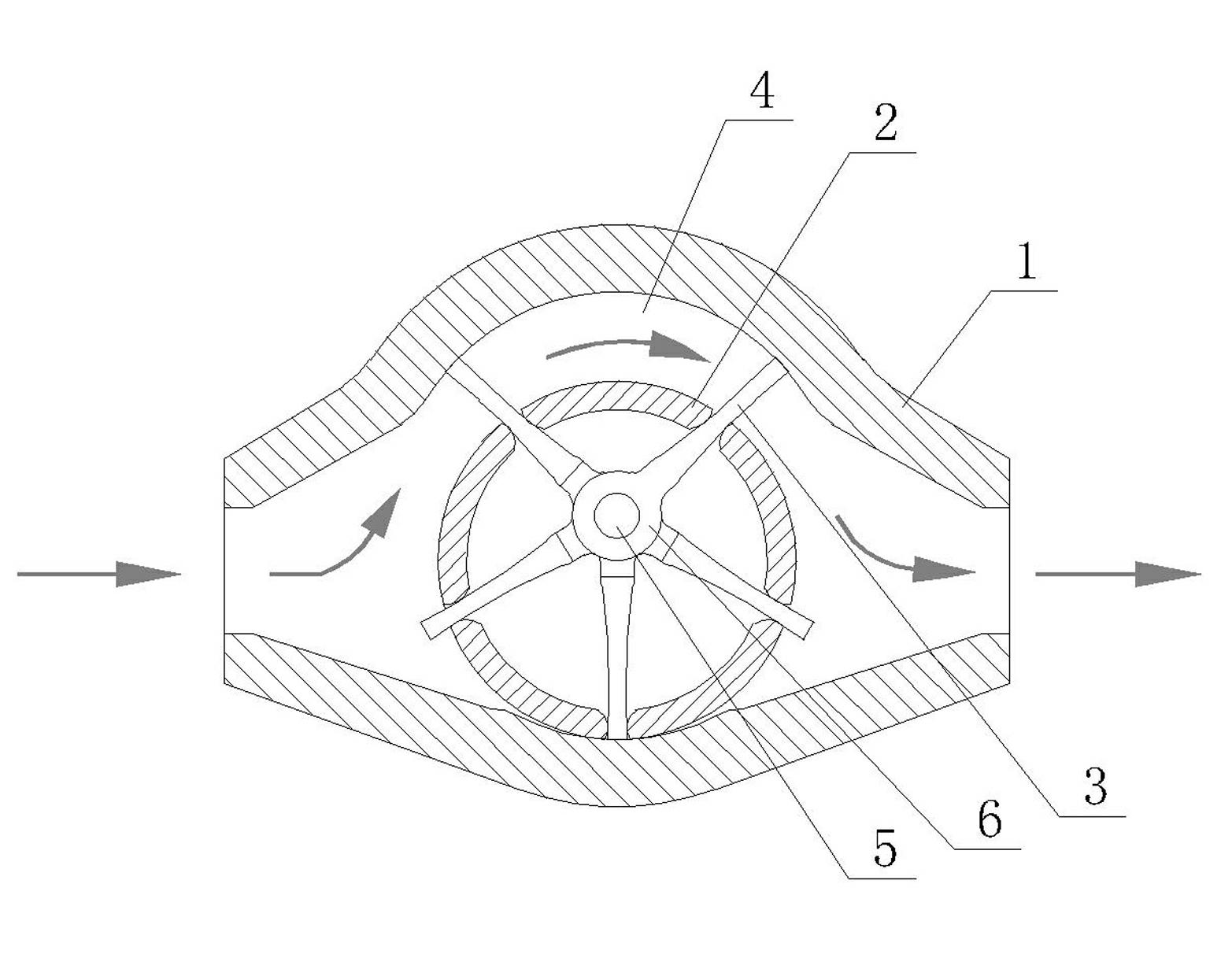

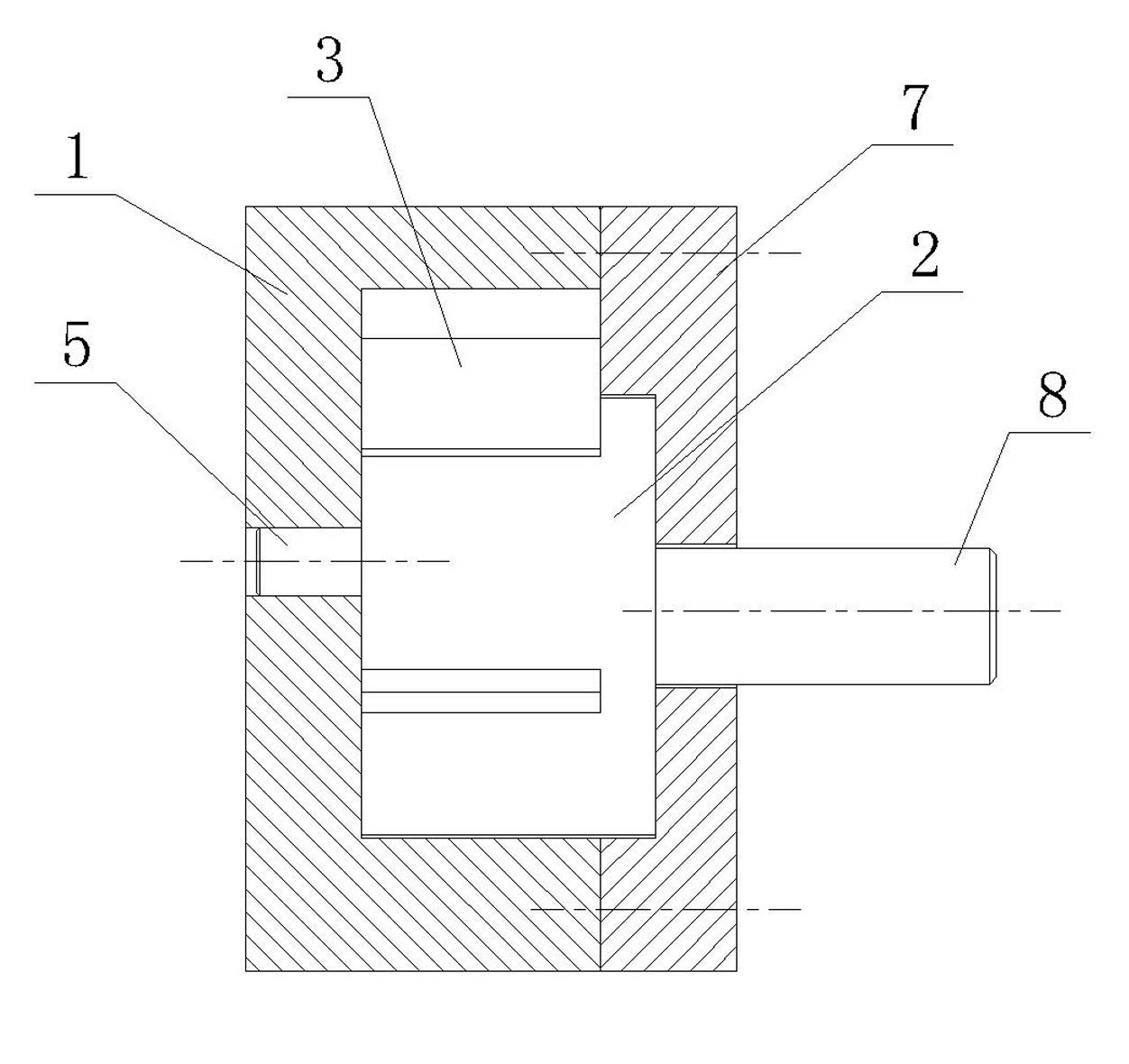

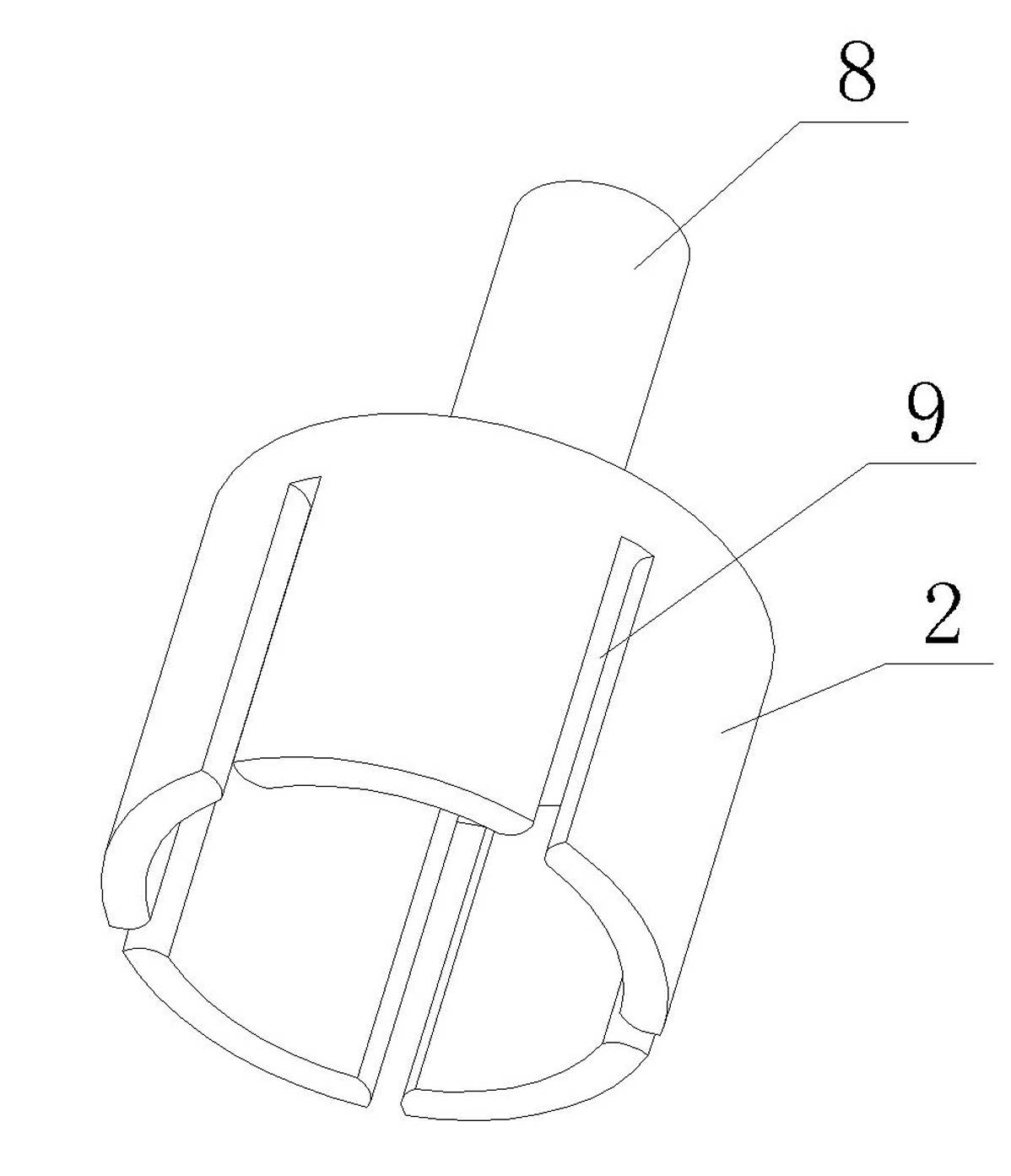

[0018] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0019] Refer to attached figure 1 , 2 , 3, 4, this kind of vane pump, including stator 1, rotor 2, vane 3 (the vane is five pieces), vane shaft 5 and end cover 7, stator 1 has the inner surface of cylindrical hole 4, end cover 7 is passed through the screw It is fixedly connected with the stator 1, and the rotor 2 is a cylinder with a radial groove 9. One end of the rotor 2 is open and has a hollow structure. The other end of the rotor 2 is connected to the prime mover. Installed in the cylindrical hole 4 of the stator, the blade 3 slides freely in the radial groove 9 of the rotor, the blade shaft 5 is installed coaxially with the cylindrical hole 4 of the stator, and the blade shaft 5 is fixed on the side cover of the stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com