Thermal expansion valve

A thermal expansion valve and displacement technology, which is applied in the field of thermal expansion valves, can solve problems such as not considering resin materials, achieve the effects of suppressing thermal influence, avoiding plastic deformation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

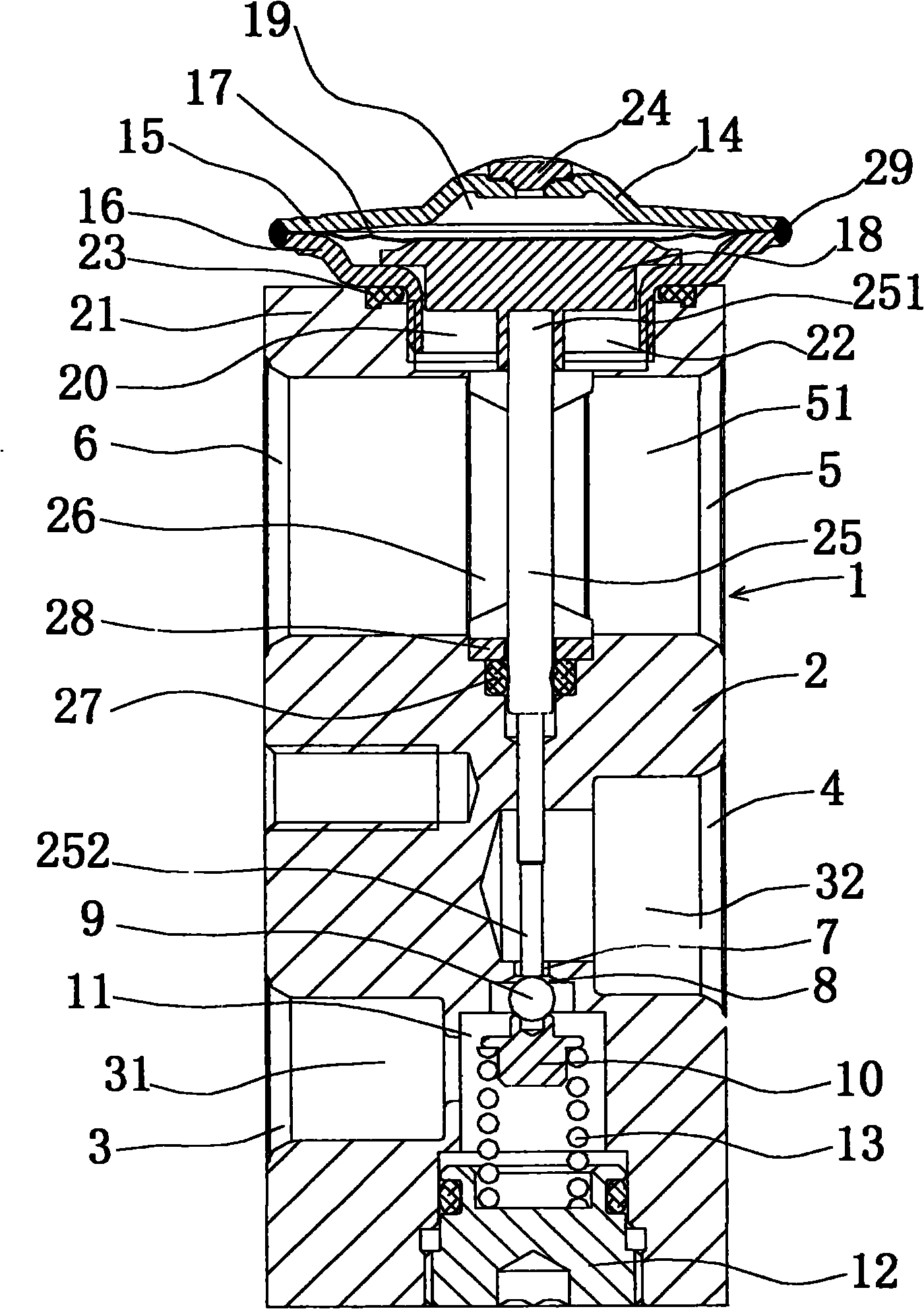

[0035] figure 1 It is a central longitudinal sectional structural view of the thermal expansion valve according to the first embodiment of the present invention.

[0036] In the thermal expansion valve 1 in the figure, connection holes 3, 4, 5 and 6 are formed on the side of the aluminum block valve body 2, wherein the connection holes 3 are connected with the high-temperature and high-pressure refrigerant from the liquid receiver for the inflow of refrigerant The connecting pipe is connected; the connecting pipe connecting hole 4 is connected to the refrigerant connecting pipe that introduces the low-temperature and low-pressure refrigerant that has been insulated and expanded by the thermal expansion valve into the evaporator; the connecting pipe connecting hole 5 is connected to the refrigerant connecting pipe at the outlet of the evaporator; and the connecting pipe The connection hole 6 is connected with the refrigerant connecting pipe that sends the refrigerant into the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com