Dedicated photoelectric encoder with special insulation structure for wind driven generator

A technology for wind turbines and photoelectric encoders, applied in the field of photoelectric encoders, can solve the problems of reduced insulation performance, loss, difficulty in adapting insulation bearings, etc., and achieves the effect of increasing the breakdown voltage value, broadening the selection range, and freeing installation and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

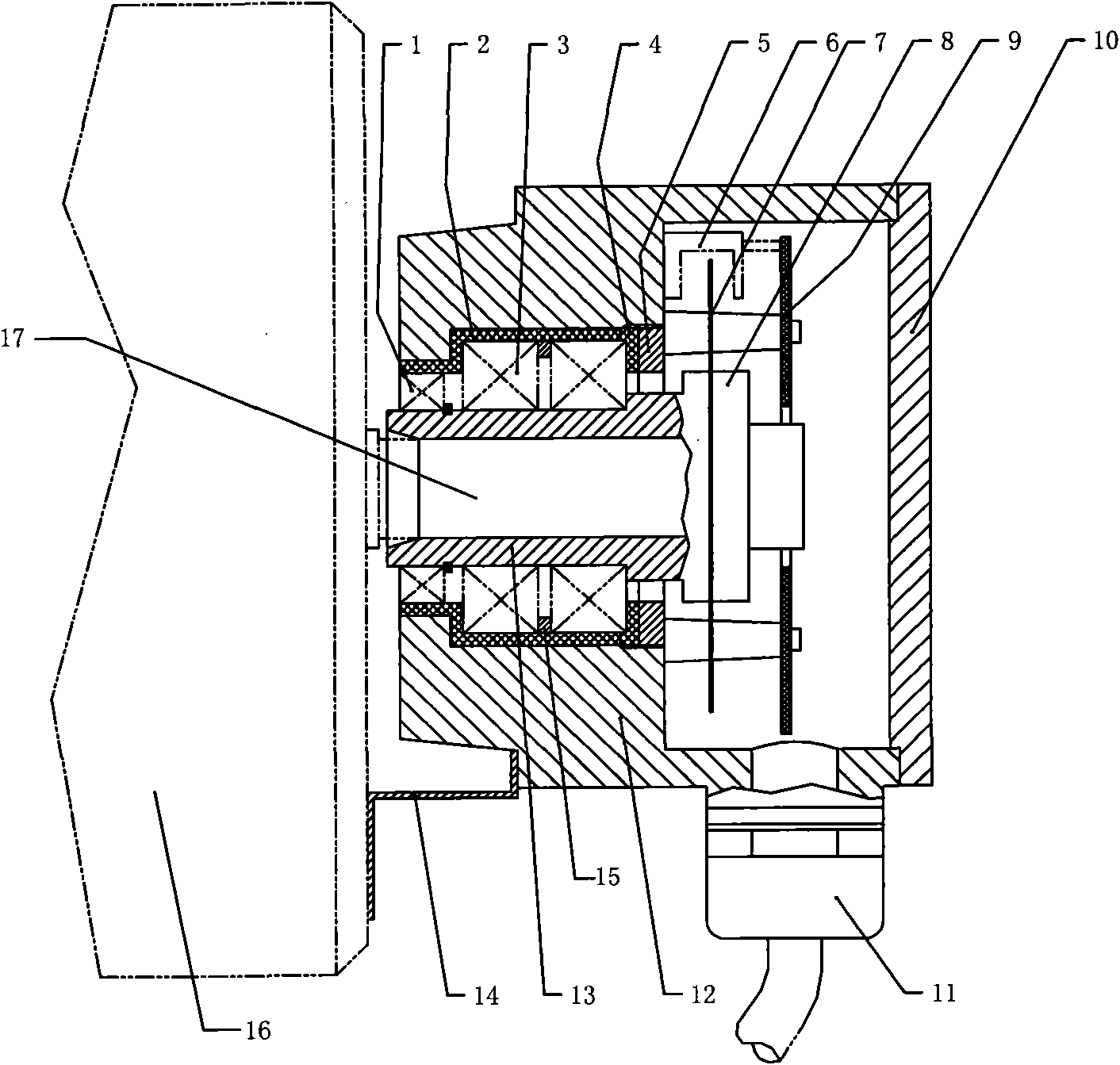

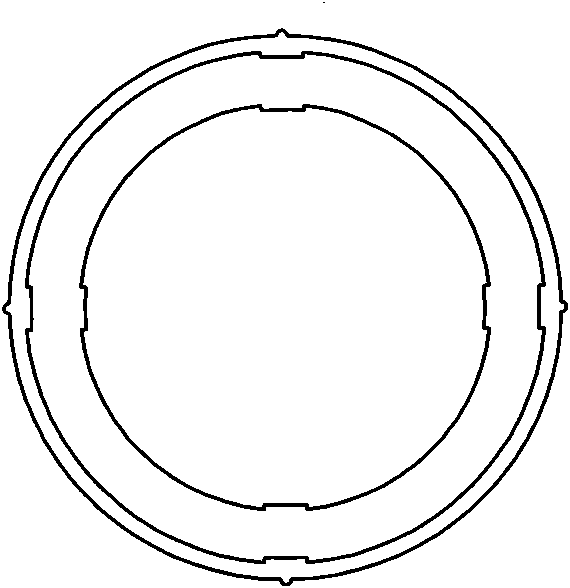

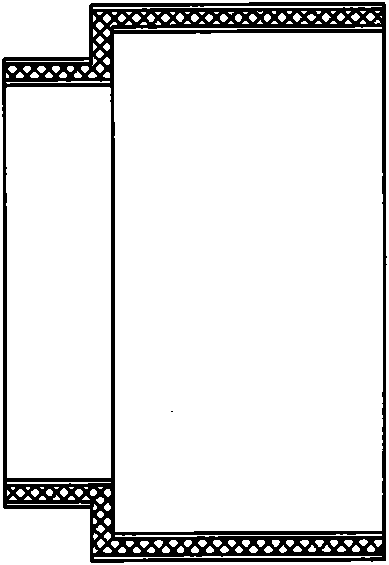

[0033] A special photoelectric encoder for wind power generators with a special insulating structure, including a seal 1, an insulating sleeve 2, a bearing 3, an insulating gland 4, a threaded pressing part 5, a photoelectric system 6, a grating disc 7, a support ring 8, and a circuit Plate 9, rear cover 10, waterproof cable connector 11, encoder main body 12, hollow shaft 13, fixing bracket 14, spacer ring 15. The hollow shaft 13 is fixedly connected with the output shaft 17 of the generator according to the precision matching requirements, and the grating disc 7 is fixed on the hollow shaft 13 by the support ring 8; 1. The threaded pressing part 5 is connected to the encoder main body 12; a spacer ring 15 is arranged between the double bearings; a photoelectric system 6 (including a light-emitting tube corresponding to the code track of the grating disk, an indicating grating and an array of photoelectric receiving elements), a circuit board 9 is installed on the main body o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com