A kind of production technology of composite blockboard

A production process and blockboard technology, applied in wood processing equipment, manufacturing tools, etc., can solve the problems of a large amount of labor and affect the quality of plywood, and achieve the effects of saving labor costs, expanding the use range, and not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

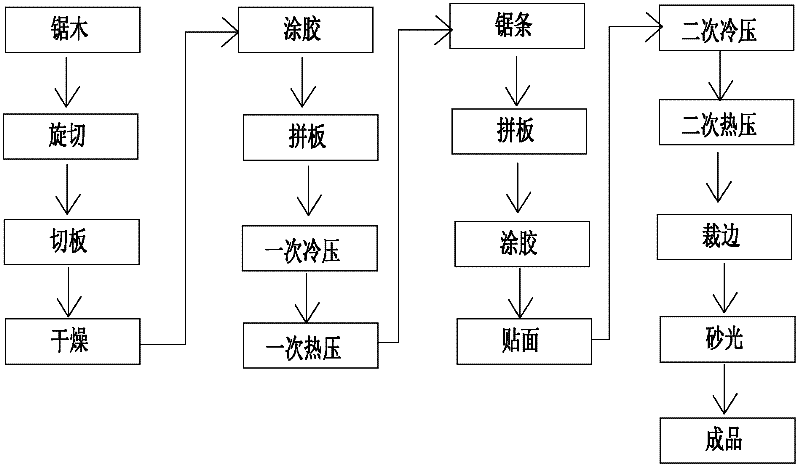

[0038] See figure 1 , this figure is the flow chart of the production technology of composite blockboard among the present invention.

[0039] The production process of the composite blockboard provided by the invention comprises the following steps: (1), sawing: timber is sawed into wood sections; (2), rotary cutting: the wood sections are rotary cut into log chips; (3) ), cutting board: cutting the original wood chips into wood chips of certain specifications; (4), drying: carrying out moisture content process on the wood chips; (5), gluing: gluing the wood chips; (6), splicing: Put several layers of glue-coated wood chips of the same specification into a composite laminate; (7), one-time cold pressing: cold-press the composite laminate; (8), one-time hot pressing: heat the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com