Multi-block one-time forming mold with convenient mold assembly and disassembly

A molding mold, a convenient technology, applied in the direction of molds, mold separation devices, etc., can solve the problems of heavy metal door panels, deformation of joint parts, etc., and achieve the effects of good product integrity, less failure, and improved labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

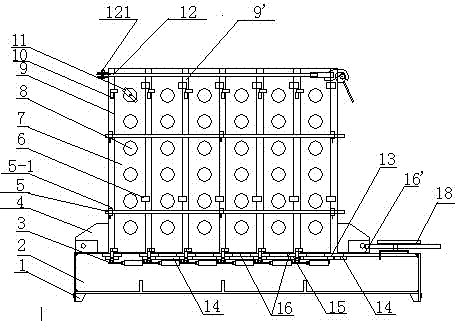

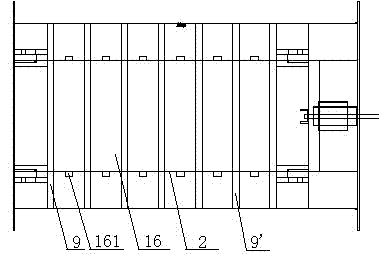

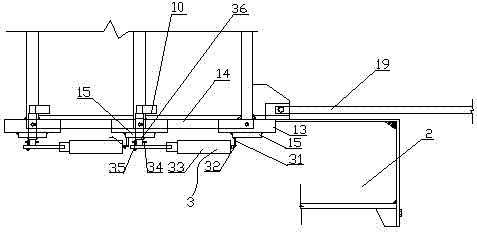

[0044] Such as Figure 1-9 As shown, the multi-block one-time molding mold with convenient assembly and disassembly includes: a base frame 2, a fixing plate 9 arranged on the left side (or right side) of the base frame and vertically fixed on the base frame, six pieces and The fixed plates are equal in size and parallel to each other with movable vertical partitions 9', the front and rear door panels 7 which are perpendicular to the fixed panels 9 or the movable vertical partitions 9' and are parallel to each other, and the front and rear door panels 7 which are arranged on the A plurality of core holes 8 corresponding to each other are inserted into the plugging tube 17 in the core hole 8; it is characterized in that: between the fixed plate 9 and the movable vertical partition 9' and two adjacent movable vertical partitions Rectangular flat plate 16 is set on the said underframe 2 between the plates 9'; front and rear door panels 7 are arranged on the sides of said fixed pla...

Embodiment 2

[0058] Example 2 is roughly the same as Example 1. The difference is that "the round platform cap 11 screwed into the core hole 3 replaces the plugging tube 17 inserted in the core hole 3. The round platform cap 11 is mainly composed of a round platform 111, a long baffle plate 112 and a fixing screw 113. Screw Move fixed screw 113, make the round flat part of round platform 111 withstand the inner wall of core hole 8 places on front and rear door panels 7, and long baffle plate 112 withstand the outer wall of core holes 8 places on front and rear door panels 7. In this way, The round platform of the round platform cap 11 has been fixed on the front and rear door panels 7. After the block forming and division, there is no through hole on the block, but there is also a round platform small hole that is convenient for swinging the block. If the round platform cap 11 round platform 111 If the part is designed to be flat and smaller, the round table hole on the side of the formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com