Nano-ceramic thermal insulation film and preparation method thereof

A nano-ceramic and heat-insulating film technology, applied in ceramic layered products, chemical instruments and methods, lamination, etc., can solve the problems of insufficient service life, poor fire resistance, easy oxidation of metal coating, etc. Effects of cleanliness, reduced water mist build-up, excellent thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

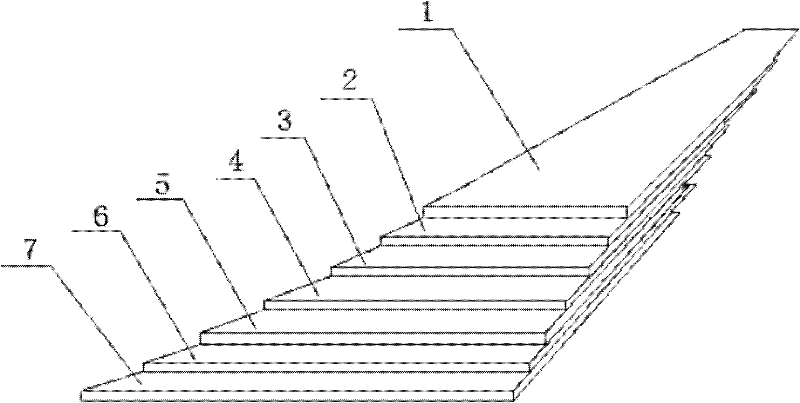

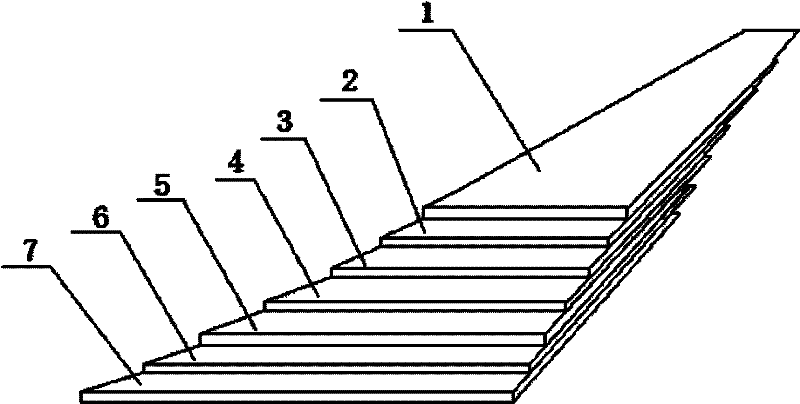

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

[0033] refer to figure 1 , nano-ceramic heat insulation film, including heat insulation film main body together with heat insulation effect. The main body of the heat insulation film is composed of a hierarchical structure. The main body of the heat insulation film includes at least two layers of composite film layers. One of the at least two layers of composite film layers is the heat insulation layer 3. The heat insulation layer 3 is made of nano ceramics Heat-insulating layer; the outside of the heat-insulating layer 3 is provided with a scratch-resistant layer 1 with scratch resistance, and the scratch-resistant layer 1 is the outermost layer of the heat-insulating film main body, so that the present invention can be scratch-resistant and prevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com