Starter motors for use in starters of internal combustion engines

A technology for starting a motor and a starter, which is applied in the direction of motor starting for an engine, starting of an engine, machine/engine, etc., and can solve problems such as the danger of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

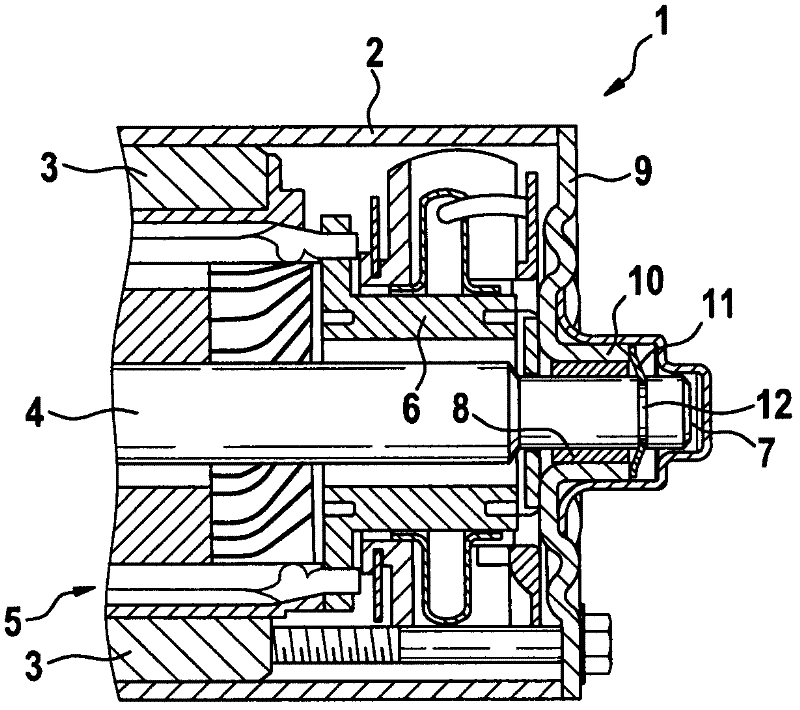

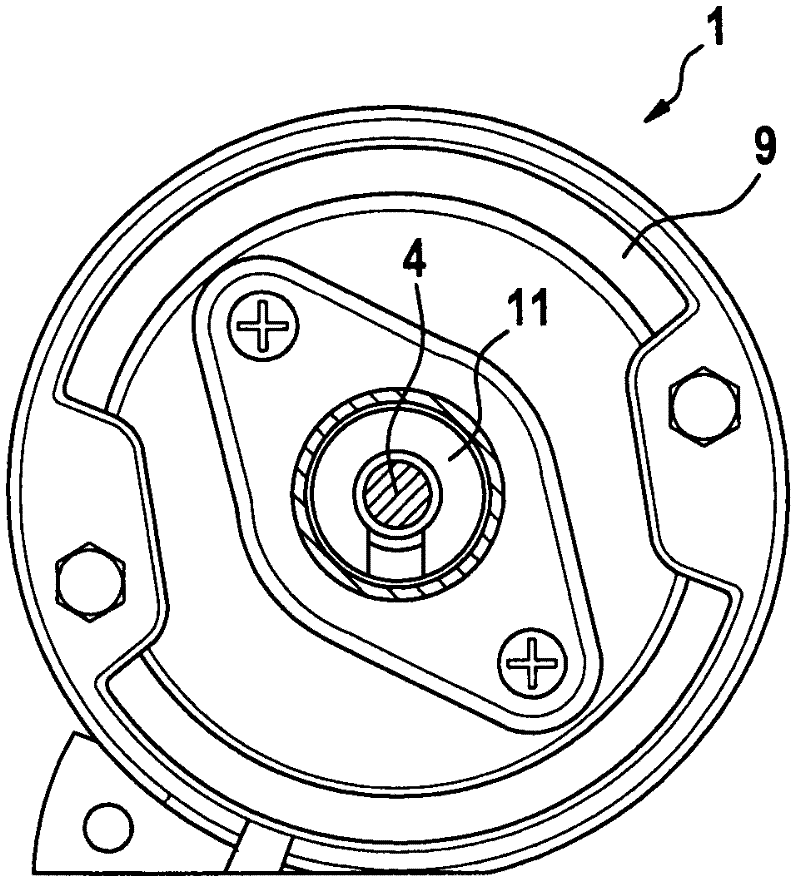

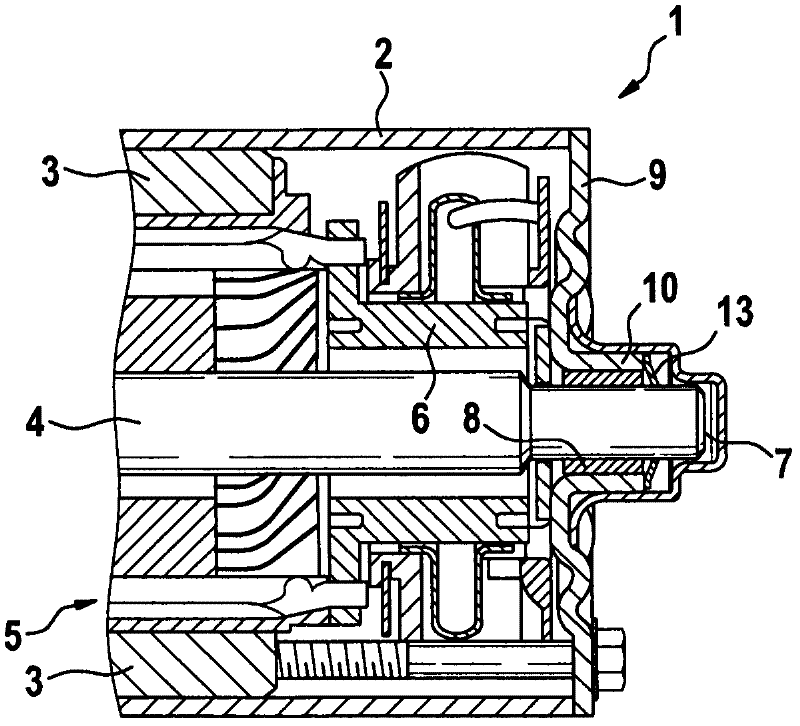

[0022] in accordance with figure 1 and figure 2 In the first embodiment of the present invention, an electric starter motor 1 is shown, which is an inner rotor motor and has a rotatably mounted drive shaft or armature shaft 4 in a motor housing or starter housing 2, said The housing has magnets arranged on the inside or pole pieces 3 with field windings. The drive shaft 4 is here, for example, a carrier for a starter pinion (not shown) which meshes in a comb-like manner with a gear wheel on the internal combustion engine. In other embodiments, the drive shaft first drives the planetary gears by means of the sun gear, which drive the starter pinion by means of the planetary carrier.

[0023] Inside the motor housing 2 , an armature 5 is pushed onto the drive shaft 4 , which armature has an armature iron plate made of laminations and an armature winding. The armature winding is energized via the commutator 6 , which comprises a slip ring fixedly connected to the drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com