Electrically driven pump

A pump chamber and flow path technology, applied in the field of electric driven pumps, can solve problems such as affecting efficiency and incapable of shortening the length of the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

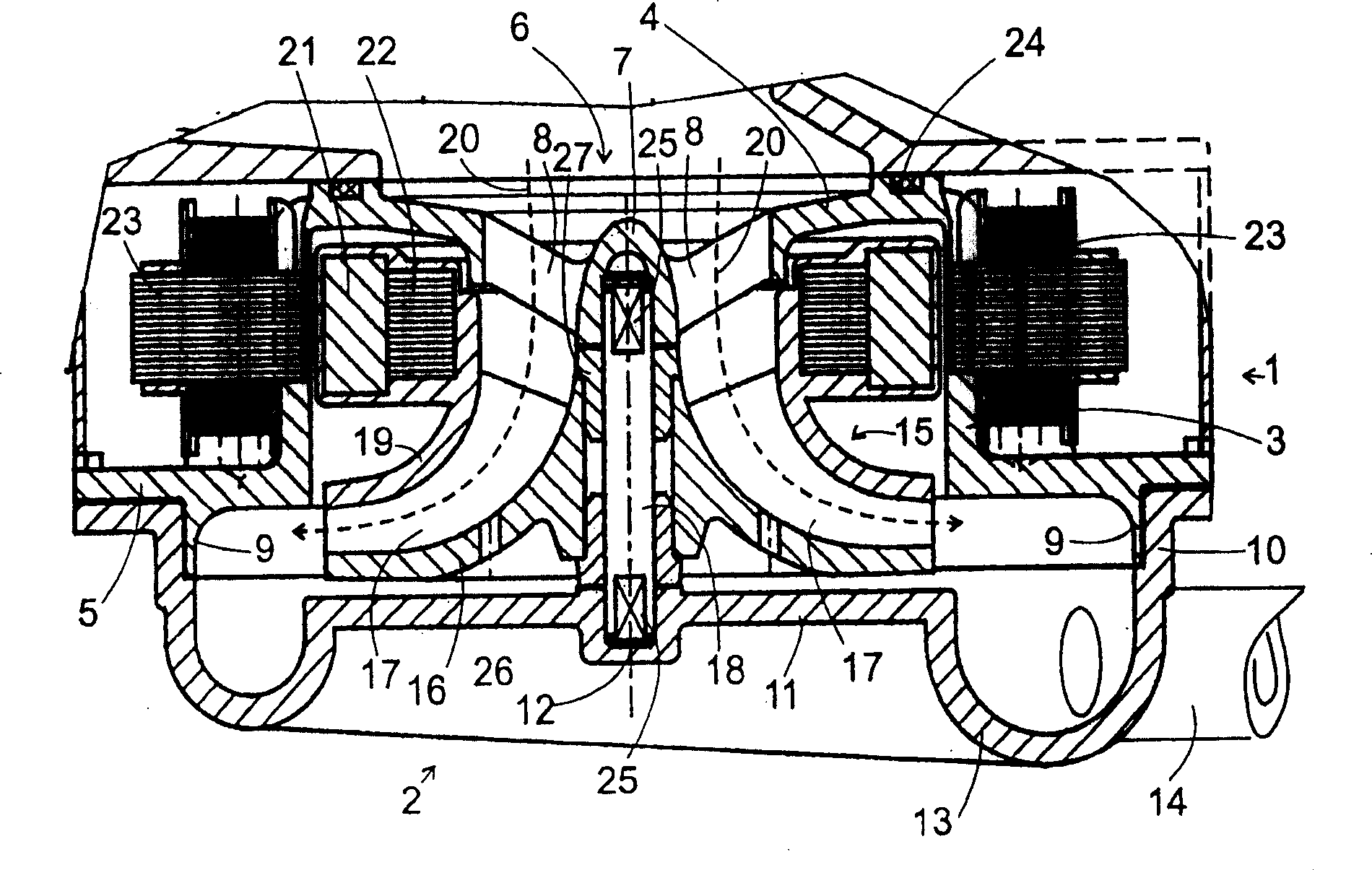

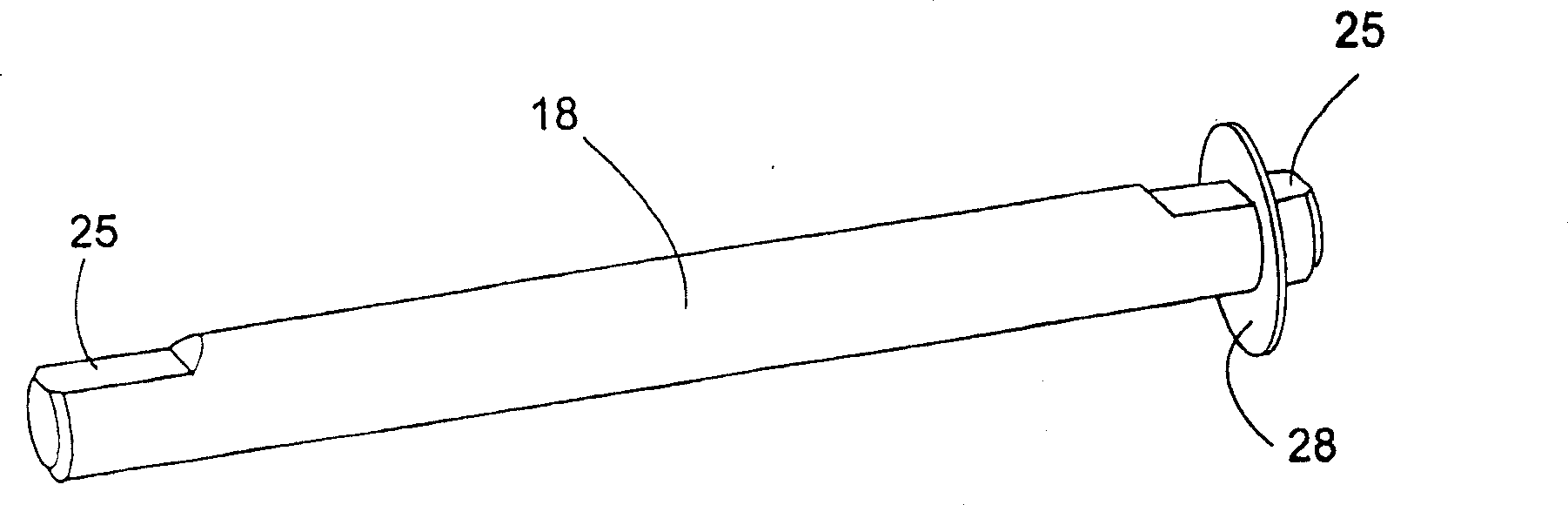

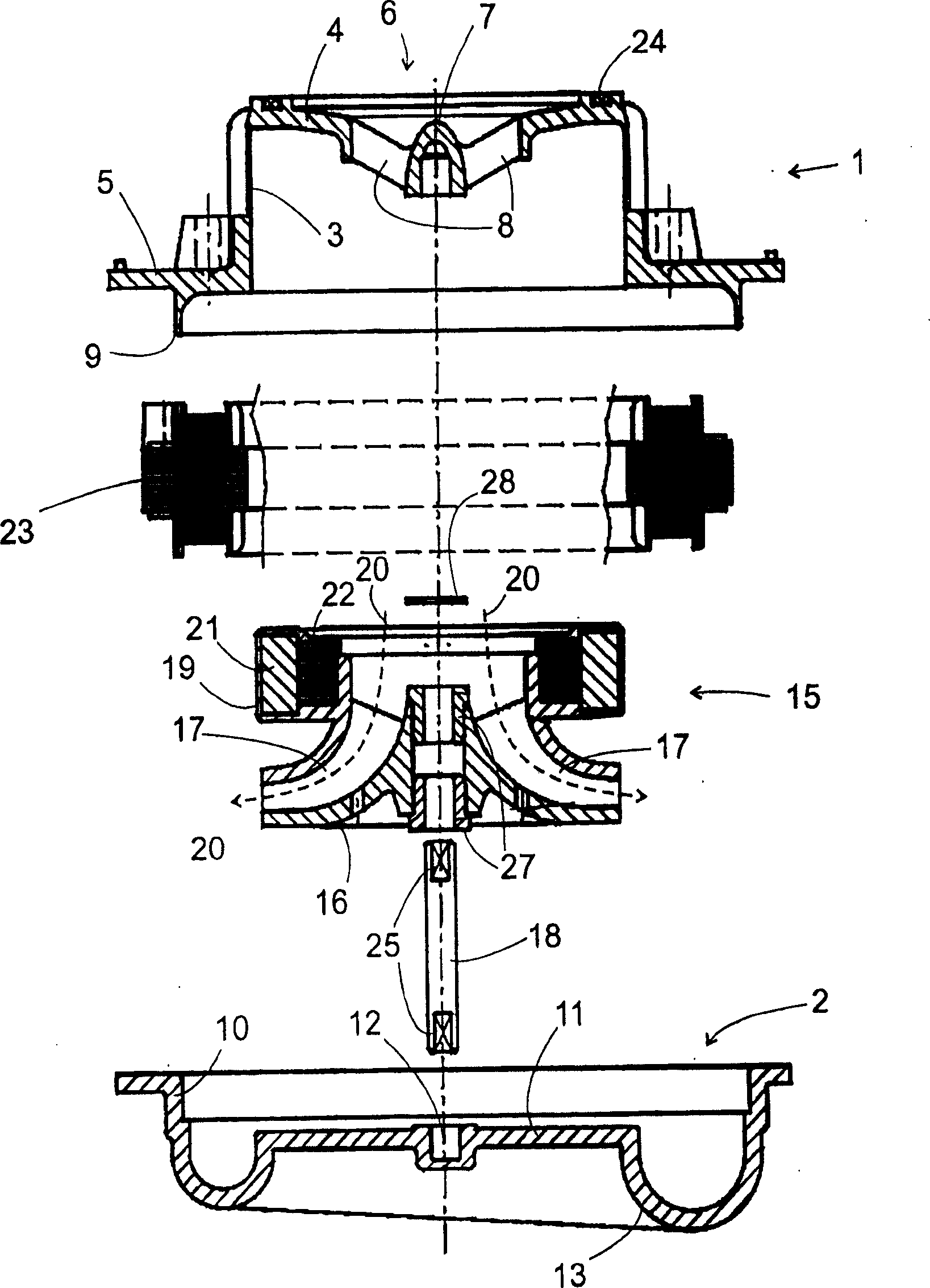

[0026] The housing of the pump consists of two parts 1 , 2 which are formed in one piece from plastic, for example by injection molding. The first housing part 1 has a cylindrical section 3 on both ends of which a shoulder 4 extending radially inwards with respect to the axis of the cylindrical section 3 and a shoulder extending radially outwards are formed 5. The inwardly extending shoulder 4 delimits an inlet 6 of the pump. In the center of the inlet opening 6 there is a socket 7 for a shaft 18 held by a support 8 which connects the socket 7 to the inwardly directed shoulder 4 .

[0027] On the side of the outwardly directed shoulder 5 facing away from the cylindrical section 3 a rib 9 is formed concentrically to the axis. The rib 9 has an inner surface that is uniformly bent into a quarter circle and a cylindrical outer surface on which a cylindrical outer wall 10 of the second housing part 2 fits. A second socket 12 is assigned to the opposite end of the shaft 18 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com