Multi-heat source annular pipe network power transmission system, system configuration method and operation mode

A ring-shaped pipe network and conveying system technology, which is applied in the heating mode, heating system, hot water central heating system, etc., can solve the problem that the conveying capacity of the multi-heat source ring-shaped pipe network heating system cannot adapt to the number of operating heat sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

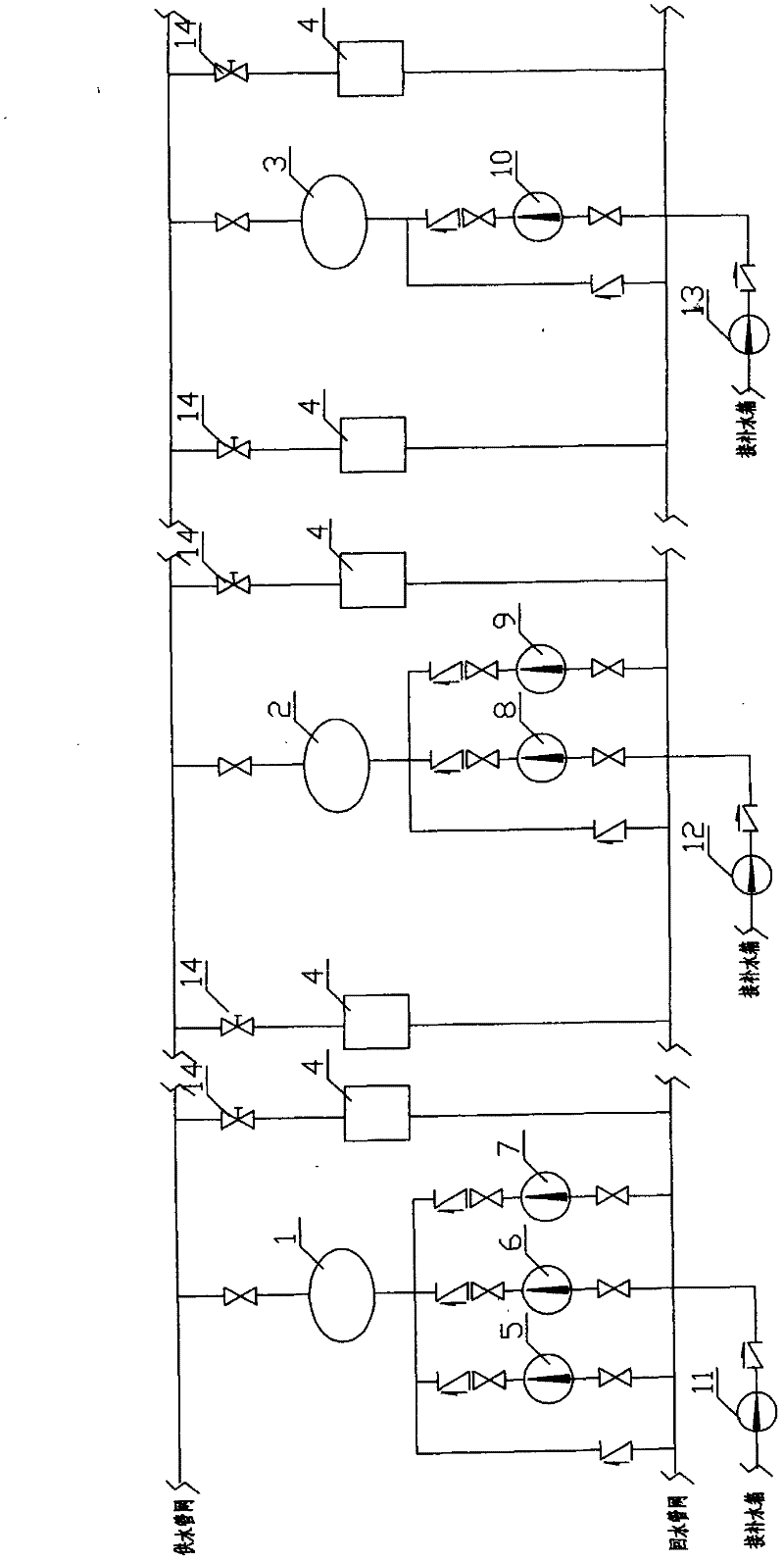

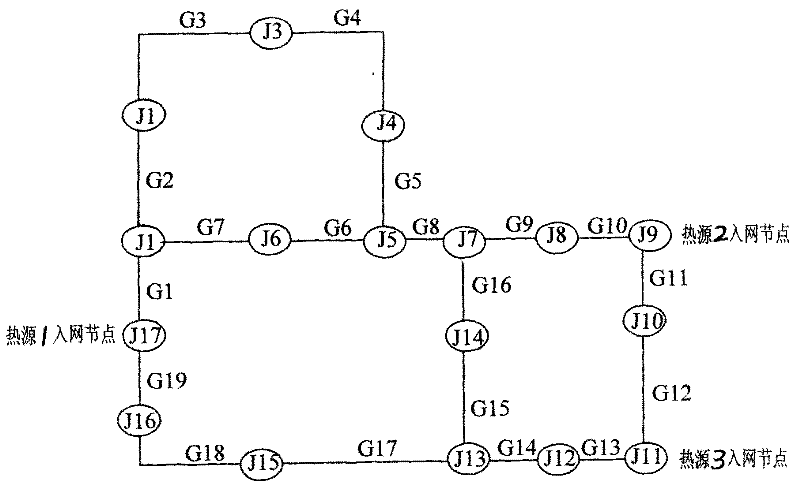

[0070] The specific implementation manner thereof will be described below in conjunction with the accompanying drawings and the workflow of the present invention.

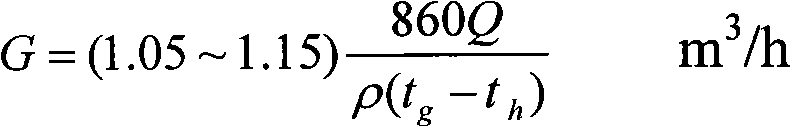

[0071] Such as figure 1 As shown, the power transmission system of the present invention comprises a power transmission system of a basic heat source 1, an adjustment heat source 2 and a peak-shaving heat source 3; figure 1 It can be seen that the basic heat source 1 is provided with a basic working condition circulating pump 5, a regulating working condition circulating pump 6, a peak regulating working condition circulating pump 7 and corresponding pipelines, valves, accessories and control systems (not shown in the figure) ; Circulating pump 8 for regulating working condition, circulating pump 9 for peak-shaving working condition and corresponding pipelines, valves, accessories and control system are arranged at 2 places of regulating heat source; Corresponding piping, valves, accessories and control systems. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com