A Composite Refrigeration System

A composite refrigeration and refrigeration cycle technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low operating efficiency, lack of methods for supplying heat sources, high-temperature sensible heat not being further utilized, etc., to improve The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

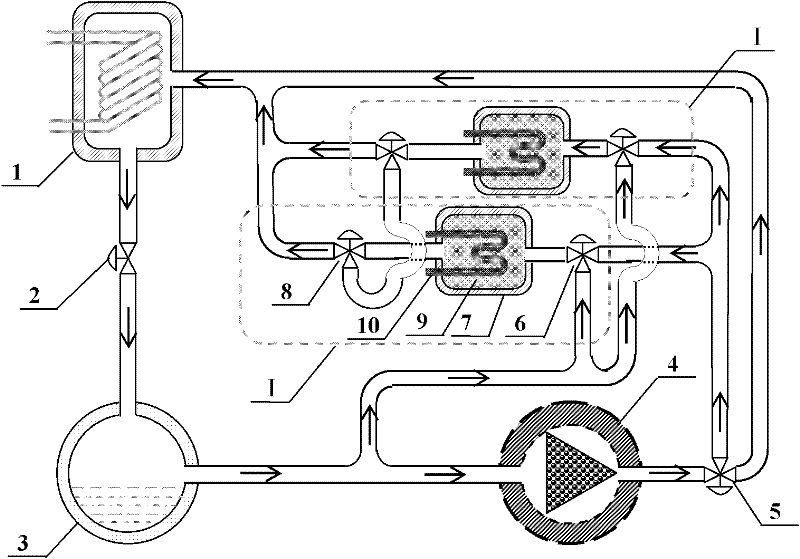

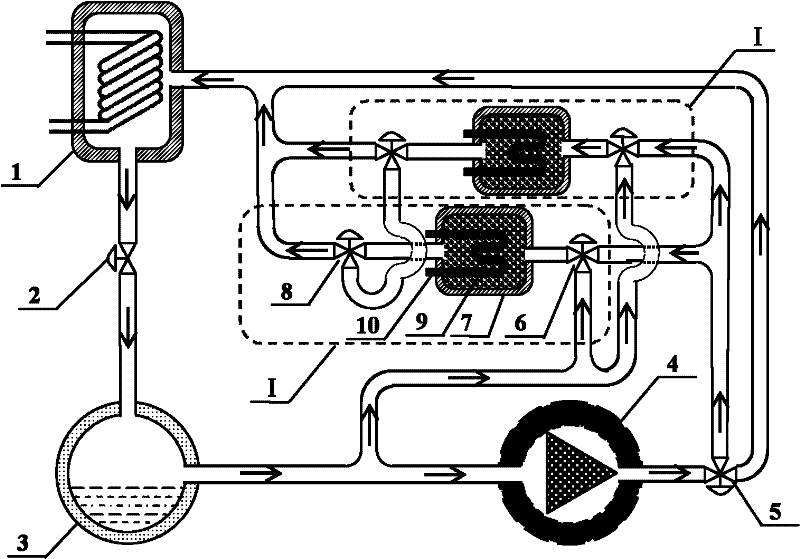

[0020] Such as figure 1 As shown, the present embodiment includes: condenser 1, throttle valve 2, evaporator 3, compressor 4, flow direction valve 5, adsorption unit 1 includes adsorption valve 6, adsorption bed 7 and desorption return quality valve 8, adsorption bed 7 Filled with adsorbent 9, the adsorption bed 7 is provided with a heat exchanger 10.

[0021] In this embodiment, the outlet of the adsorption valve 6 in the adsorption unit 1 is connected to the inlet of the adsorption bed 7, the outlet of the adsorption bed 7 is connected to the inlet of the desorption valve 8, and the lower ports of the desorption valve 8 in different adsorption units 1 are connected through pipelines to form Regeneration channel; the outlet of evaporator 3 is connected to the lower inlet of adsorption valve 6, the outlet of compressor 4 is connected to the inlet of flow direction valve 5, the right outlet of flow direction valve 5 is connected to the inlet of condenser 1, the upper outlet of ...

Embodiment 2

[0025] In this embodiment, the number of the adsorption units is four.

[0026] In this embodiment, the composite refrigeration system is driven by electric energy. When the compressor is running, the left port of the flow direction valve is connected to the upper port, and each adsorption unit goes through four states in turn: evaporation adsorption state, mass return state, compression thermal desorption state, and mass return state, completing a refrigeration cycle. During operation, one adsorption unit is always in the state of evaporation and adsorption, one adsorption unit is in the state of compression thermal desorption, and the two adsorption units are in the state of mass recovery.

[0027] The rest of the process of this embodiment is the same as that of Embodiment 1.

[0028] In this embodiment, the cooling efficiency (COP) of the system can be increased by 0.3-0.6.

Embodiment 3

[0030] In this embodiment, the number of the adsorption units is 3.

[0031] In this embodiment, the composite refrigeration system is driven by electric energy. All the adsorption units are closed, the compressor is running, and the left and right ports of the flow direction valve are connected to perform pure electric compression refrigeration.

[0032] The rest of the process of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com