Method for predicting negative bias temperature instability (NBTI) service life of pMOSFET (P-channel Metal Oxide Semiconductor Field Effect Transistor) device

An instability and life prediction technology, applied in the direction of single semiconductor device testing, etc., can solve the problems of not considering the simultaneous application of voltage on the gate and drain, limiting the life of the device, and large devices, so as to save the cost of test equipment and failure time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

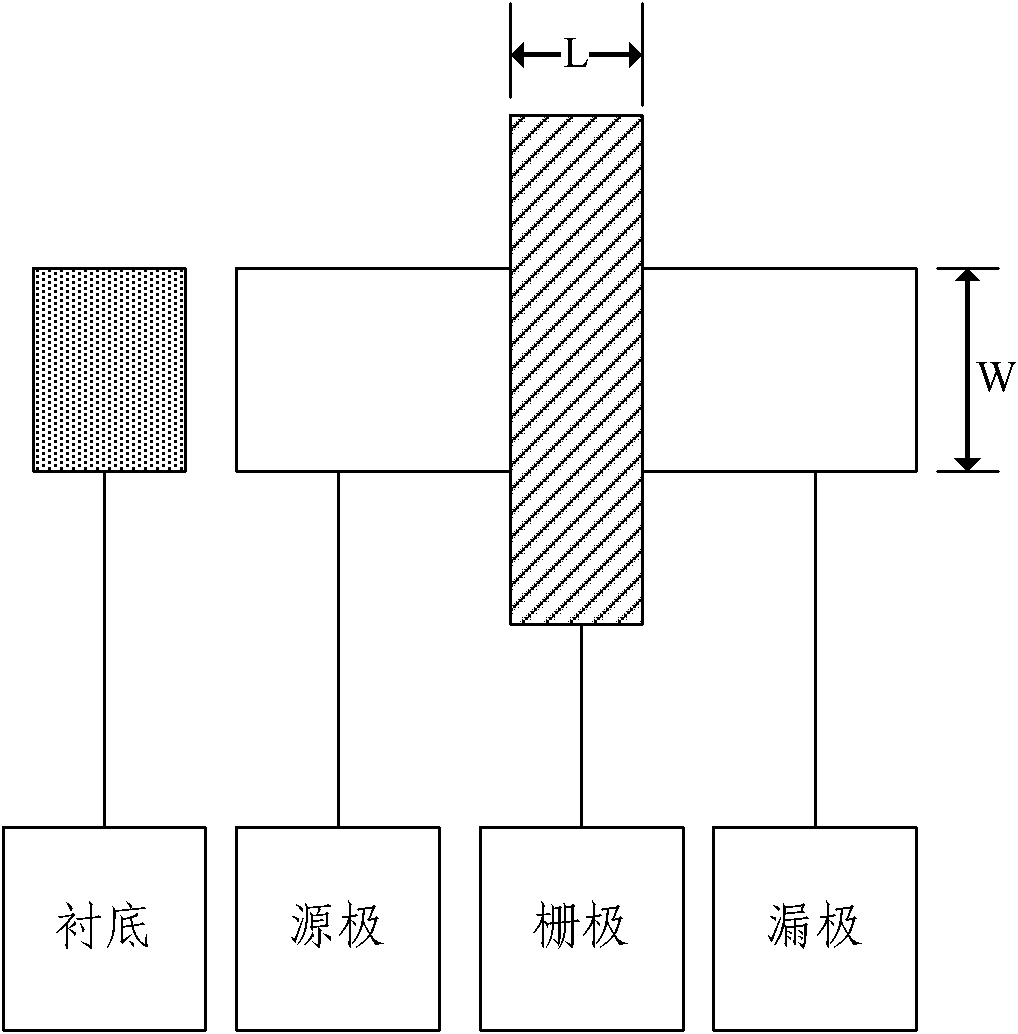

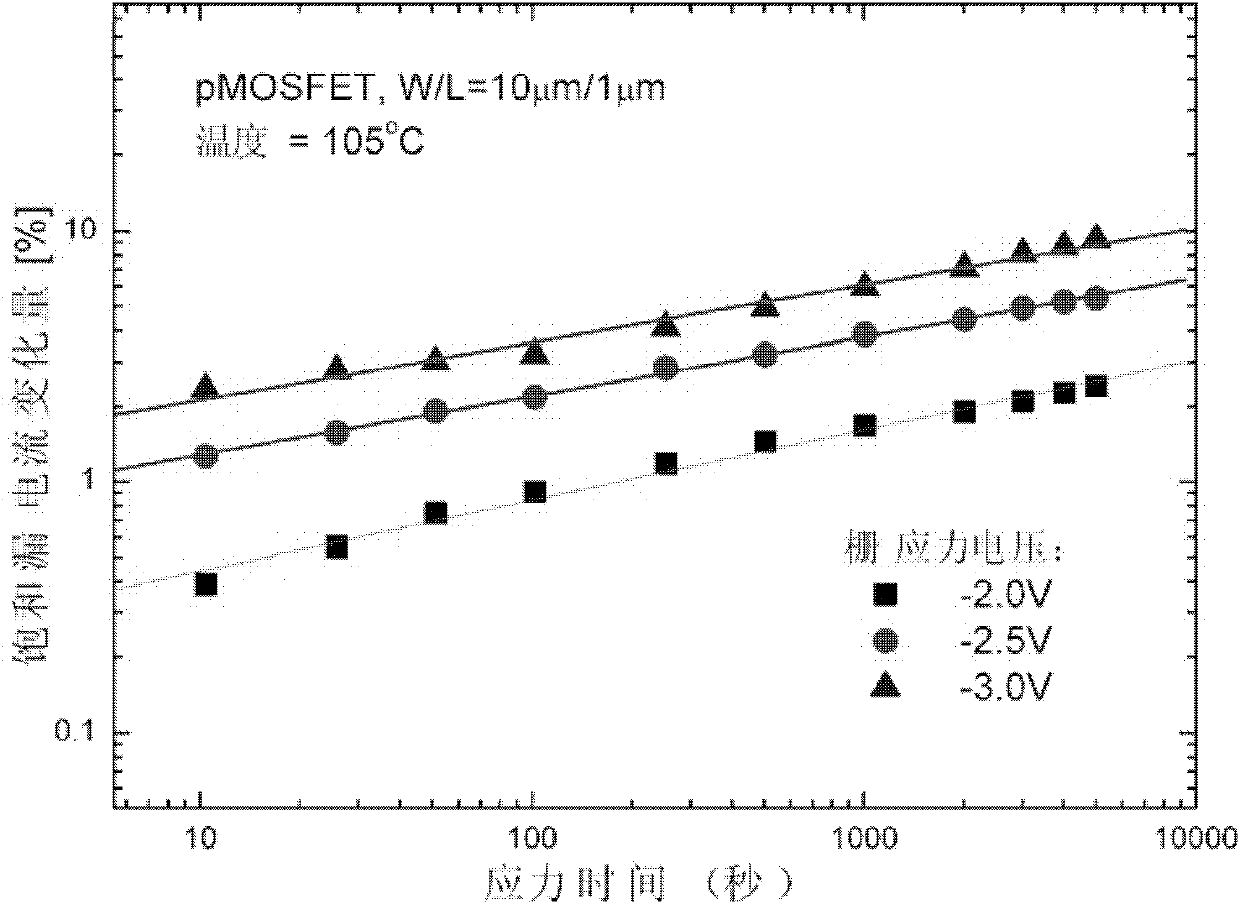

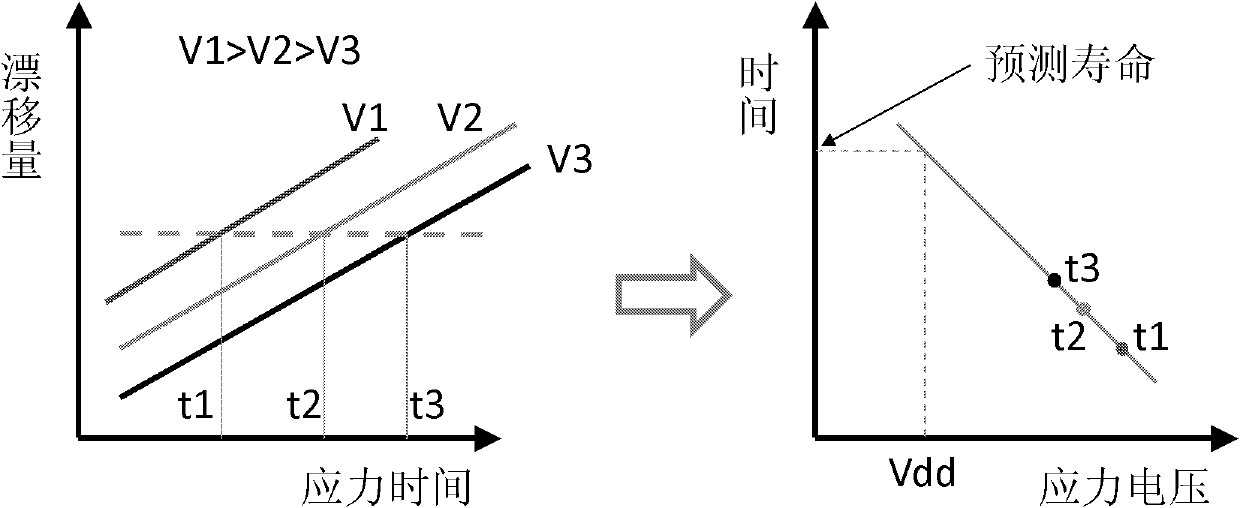

[0025] Starting from the bias state of the device in actual work, this patent proposes a method for predicting the life of a pMOSFET device by applying a normal power supply voltage to the drain while accelerating stress through a negative bias on the gate, combined with a short channel device structure. This prediction method is not only biased closer to the real working conditions of the device, but under the same gate stress, the device failure time is shorter than the conventional method, so it can better reflect the NBTI life of the pMOSFET device. This method uses a short channel device structure, such as figure 1 As shown, where L is the shortest channel length, a normal power supply voltage is applied to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com