Preparation method of low-dimensional structure thermoelectric material

A thermoelectric material and dimensional structure technology, applied in the manufacture/processing of thermoelectric devices, etc., can solve problems such as low work efficiency and few types of related materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The preparation method of the low-dimensional structure thermoelectric material comprises the following steps:

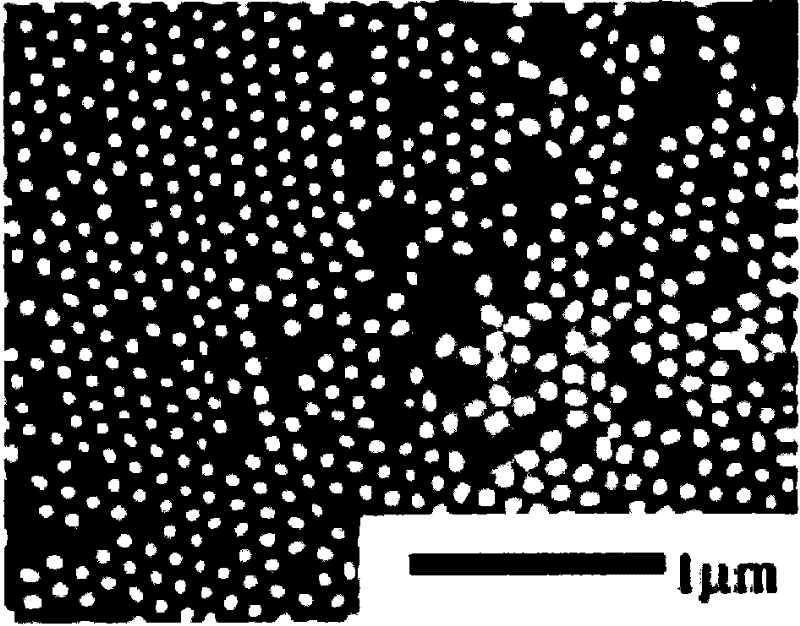

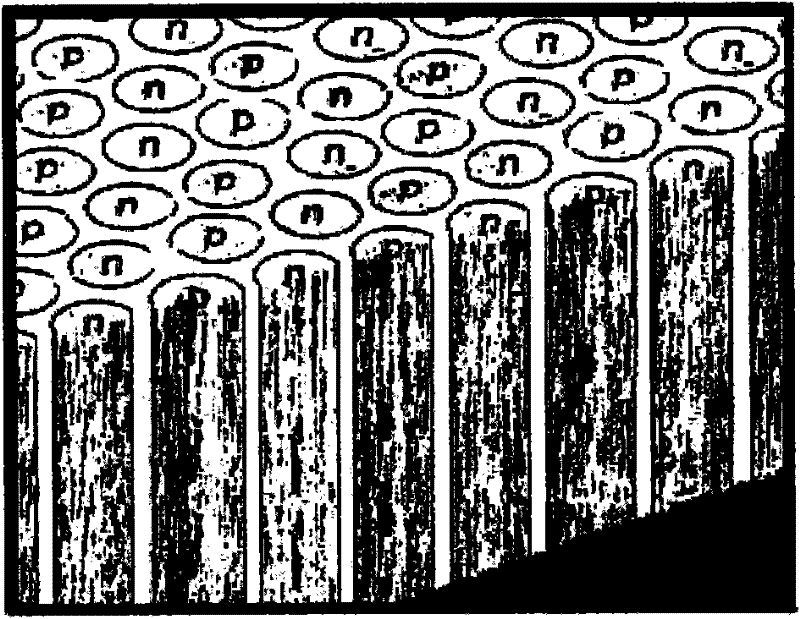

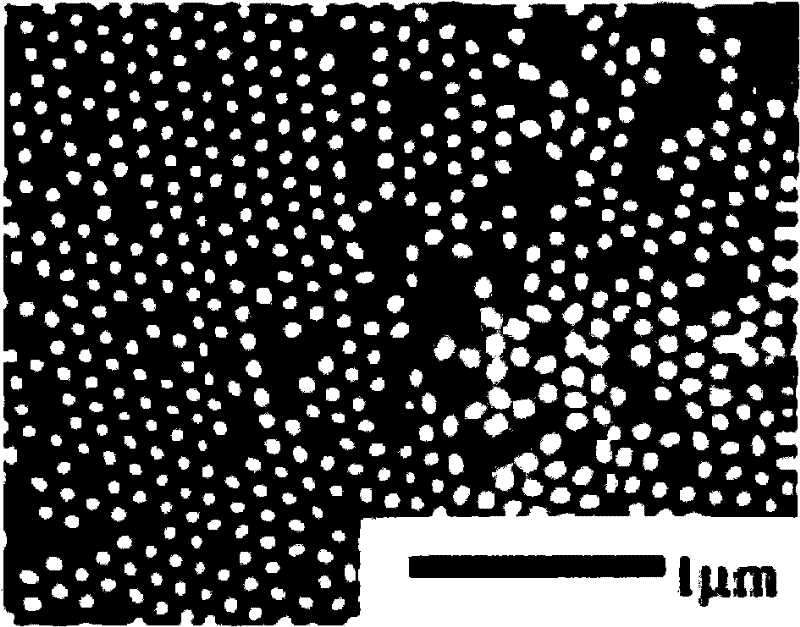

[0019] Firstly, the nanowire superlattice composite structure thermoelectric thin film is prepared based on the porous alumina template. The specific method is to adopt the cathode electrode preparation process of the cross structure, and through the electrochemical deposition method, with direct current or pulse excitation, respectively in the hole of the porous alumina template. P-type and N-type thermoelectric materials arranged alternately in the deposition process, real-time in-situ doping can be performed during the deposition process, such as figure 2 As shown, the p-type and n-type semiconductor nanowires deposited in the holes of the porous alumina template are arranged alternately. The porous alumina template her...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com