A form-plate mechanically loaded creep aging forming device

A technology of creep aging forming and mechanical loading, which is applied in the field of aviation manufacturing engineering to achieve the effects of easy replacement, reasonable conception and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

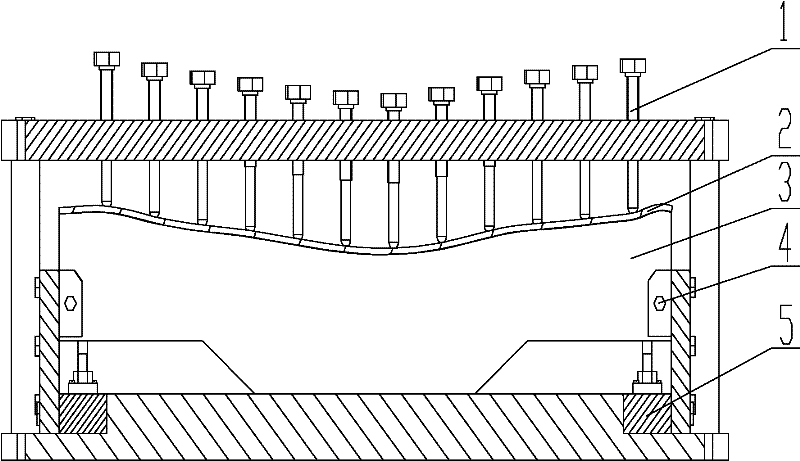

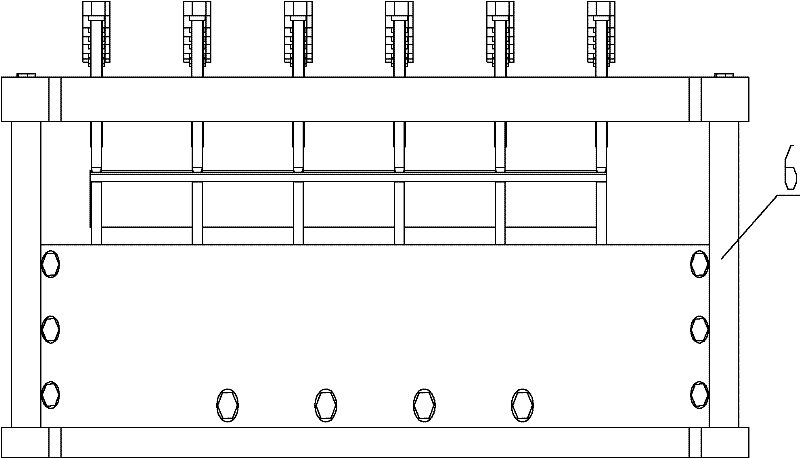

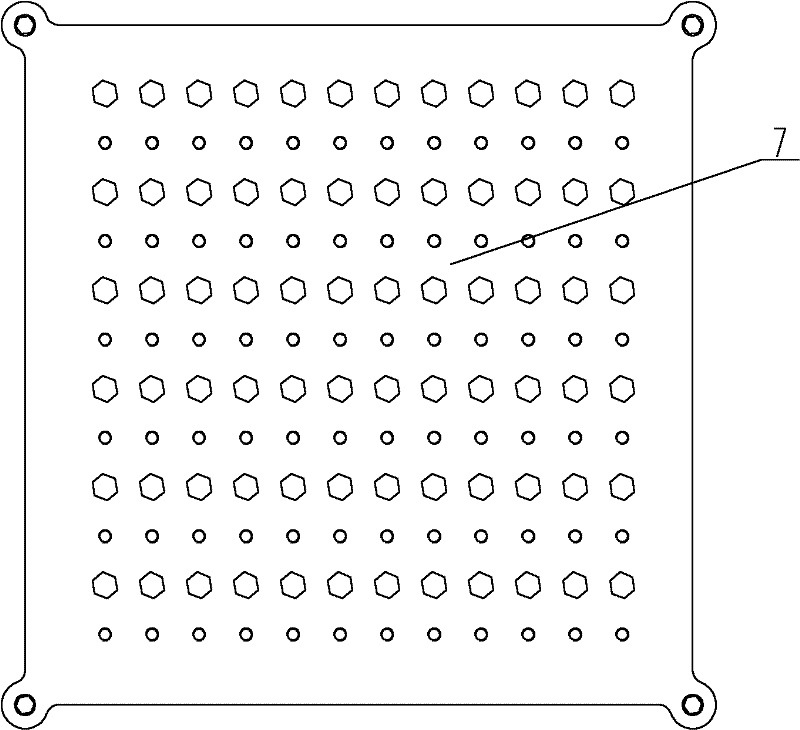

[0026] This embodiment is a shaped plate type mechanically loaded creep aging forming device for the outer skin of an aircraft wing, see Figure 1-5 , a form-plate type mechanically loaded creep aging forming device comprising: a base plate 12, an upper plate 7, a form plate 3, a pillar 6, and nail strips 5, the base plate 12 is provided with a rectangular boss, and on the rectangular boss A nail slat 5 is respectively arranged on the opposite pair of sides, and is connected by bolts between the nail slat 5 and the base plate 12; along the axial direction of the nail slat 5, there are several supporting nail columns 8, and two nail slats The height requirements of the symmetrical two supporting nail columns 8 are consistent; a guide plate 10 perpendicular to the base plate 12 is respectively arranged at the two ends of the length direction of the nail strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com