Ultra-high speed cutting three-dimensional dynamic force test platform

A three-dimensional dynamic and test platform technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve problems such as vibration mode interference, natural frequency drop, strong nonlinear vibration interference, etc., to achieve reliable work , Simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

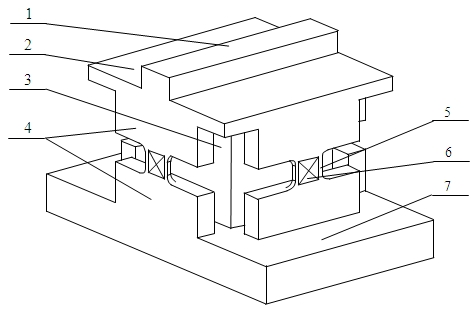

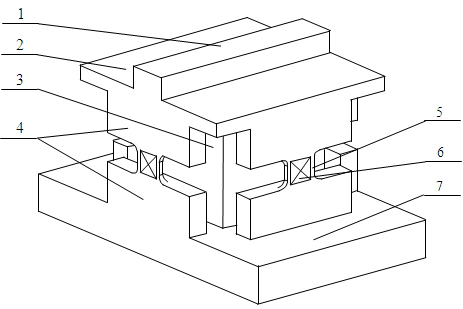

[0017] The structure and working process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the present invention provides a three-dimensional dynamic force test platform for ultra-high-speed cutting, which is an integral structure directly processed from a block-shaped blank of the processed material and affixed with a group of resistance strain gauges, including a structure to be cut 1 , upper surface platform 2, elastic cylinder 3, elastic slab 4, elastic sheet 5, resistance strain gauge group 6 and support base 7, wherein, support base 7 is positioned at the bottom, plays a supporting role; elastic cylinder 3 Located on the support base 7, in this embodiment, the elastic cylinder 3 is located at the center of the support base 7, and in consideration of the processing cost, a regular square prism structure is adopted; eight elastic slabs 4 are designed, of which two elastic slabs 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com