Online perforating device of linear cutting machine

A wire-cutting machine tool and punching device technology, which is used in attachments, electric processing equipment, metal processing equipment, etc., can solve the problem of inability to punch wire holes online, and achieve the effect of avoiding precision loss and improving processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

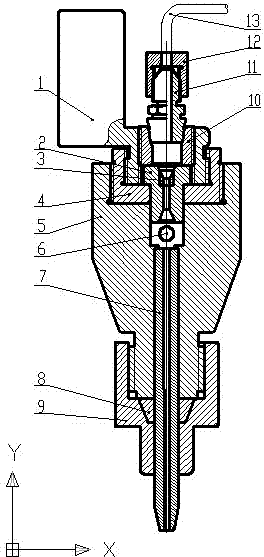

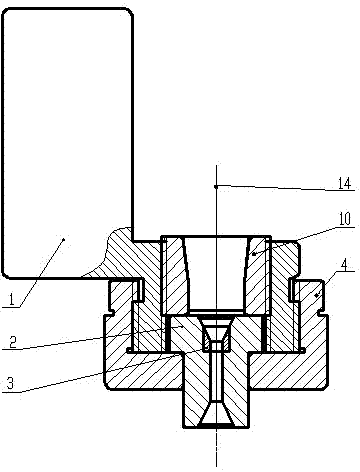

[0016] Embodiment 1: Referring to Fig. 1 and Fig. 3, the connecting seat (4) is threadedly connected with the wire frame (1), the jewel nozzle seat (2) is put into the connecting seat (4), and the outer circle of the pressing ring (10) is connected to the The wire frame (1) is threaded, and the gem nozzle seat (2) is pressed and fixed on the wire frame (1) by screwing the thread. The gem nozzle seat (2) is embedded with a gem nozzle (3), and there is a mixing chamber (6 ) of the abrasive nozzle seat (5) is threaded on the connection seat (4), and one end extends into the focusing tube (7) in the abrasive nozzle seat (5) that communicates with the mixing chamber (6), and the outer circle of the focusing tube (7) is set The tapered rubber washer (8), the compression nut (9) is threadedly connected with the abrasive nozzle seat (5), the focusing tube (7) is fixed on the abrasive nozzle seat (5), the quick change joint body (11) is connected with the compression The ring (10) is c...

Embodiment 2

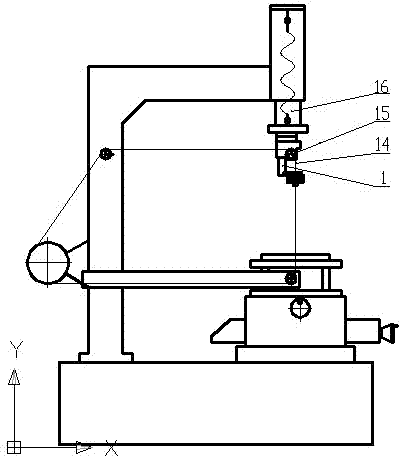

[0019] Embodiment 2: Refer to Fig. 2 and Fig. 3, after the water jet has finished piercing the wire hole, keep the X and Y worktables still, raise the lifting arm (16) of the wire frame of the wire cutting machine tool, and remove the abrasive nozzle seat (5) And focusing tube (7), tapered rubber washer (8), lock nut (9), quick change joint body (11) and joint (12), and molybdenum wire (14) passes through the center of the jewel nozzle (3) The small hole, the molybdenum wire is threaded to form a closed loop, and the normal wire cutting process can be carried out. At this time, the gemstone nozzle is used as a molybdenum wire positioner (wire guide nozzle) for wire cutting. Since the punching and the wire-cutting process are based on the same positioning reference, the accuracy of the wire-cutting process is guaranteed.

[0020] There are tapered openings at both ends of the above-mentioned jewel nozzle seat (2), which is convenient for threading. The inner diameter of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com