Multi-station synchronous transmission step indexer for curved surface printing machine

A synchronous transmission, multi-station technology, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of complex processes, long transmission routes, and many transfers, so as to improve economic benefits, clear printing effects, and improve printing. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, its specific implementation, structure, Features and their functions are described in detail below.

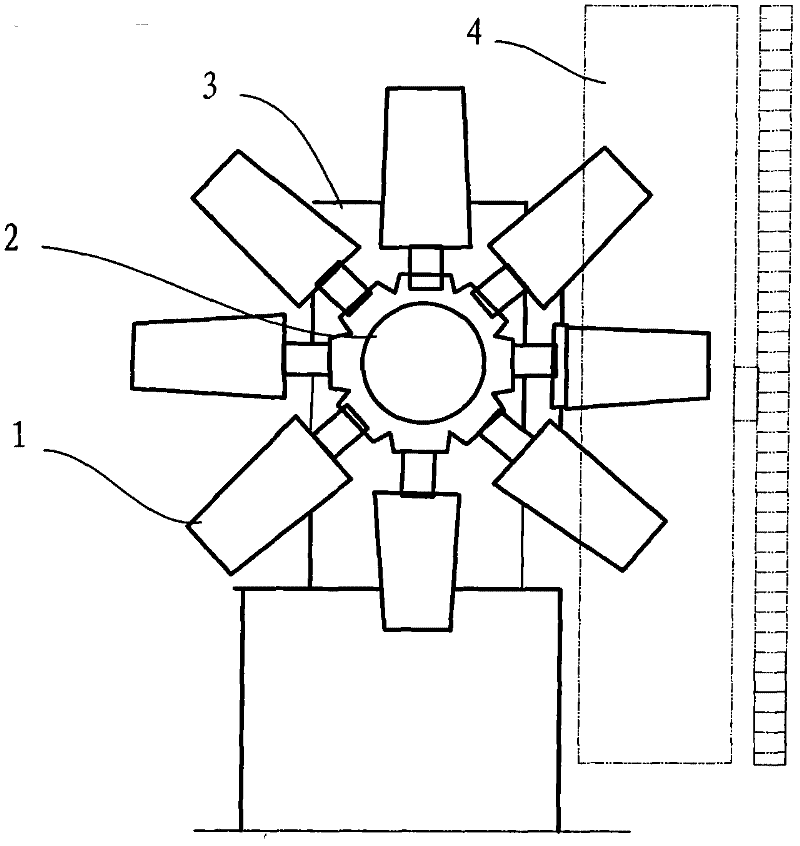

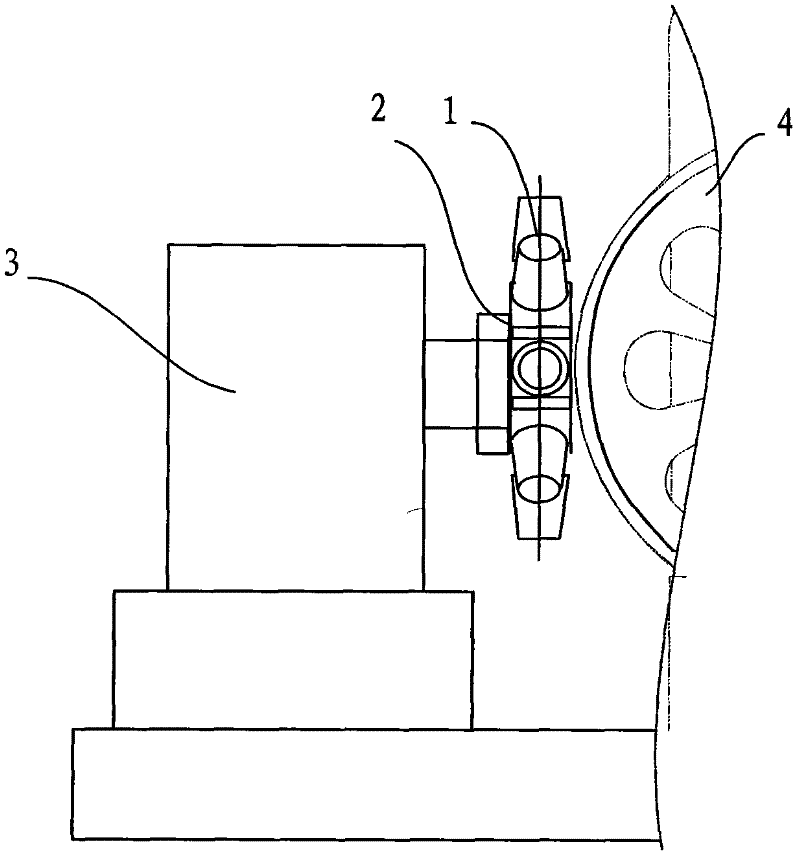

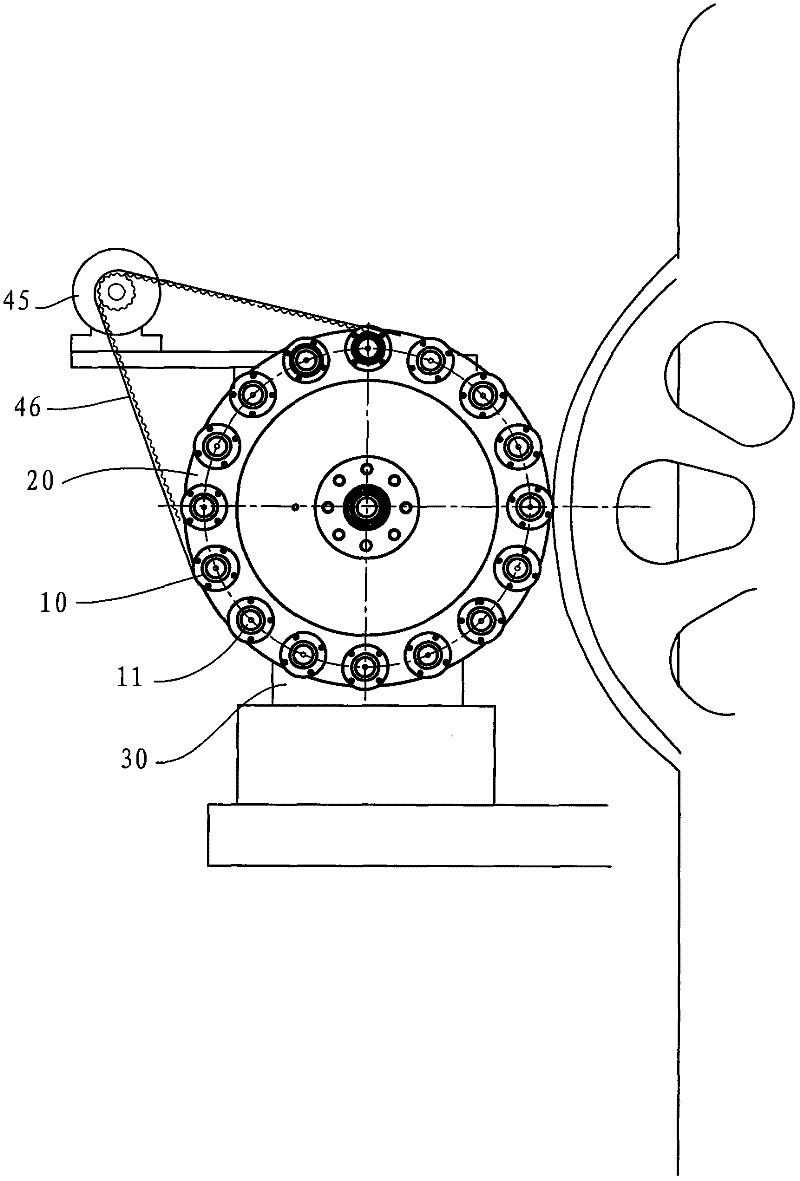

[0036] see image 3 , Figure 4 , Figure 5 As shown, the multi-station synchronous transmission step indexer of the preferred embodiment of the present invention mainly includes: an indexing turntable 20 provided with a plurality of mold handles 10, an intermittent drive device 30 for driving the rotation of the indexing turntable 20, and a mold The drive system 40 and the air system 50, wherein the axes of the plurality of die handles 10 are parallel to the axis of the indexing turntable 20; the die handle drive system is a synchronous drive system, which includes planetary gears 41, ring inner The ring gear fixing seat 42, the fixing seat support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com