Automobile brake drum automatic circulation cooling system and control method

An automatic cycle, automobile braking technology, applied in the direction of brakes, vehicle parts, cooling brakes, etc., can solve the problems of wasting water resources, high fuel consumption under vehicle load, ablation of hub bearings, etc. The effect of meeting cooling requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

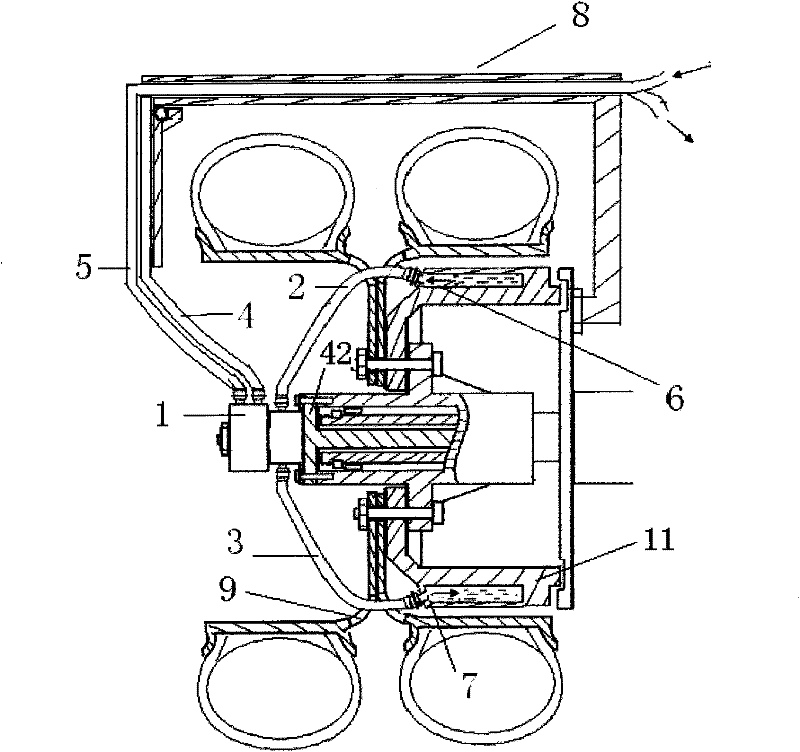

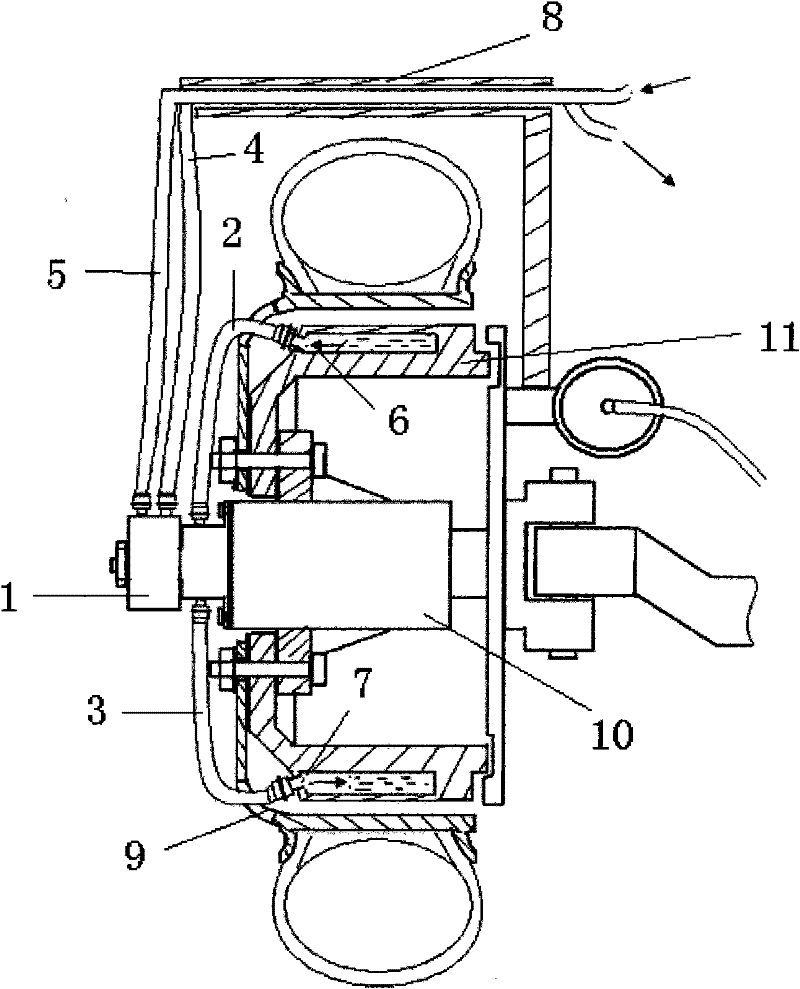

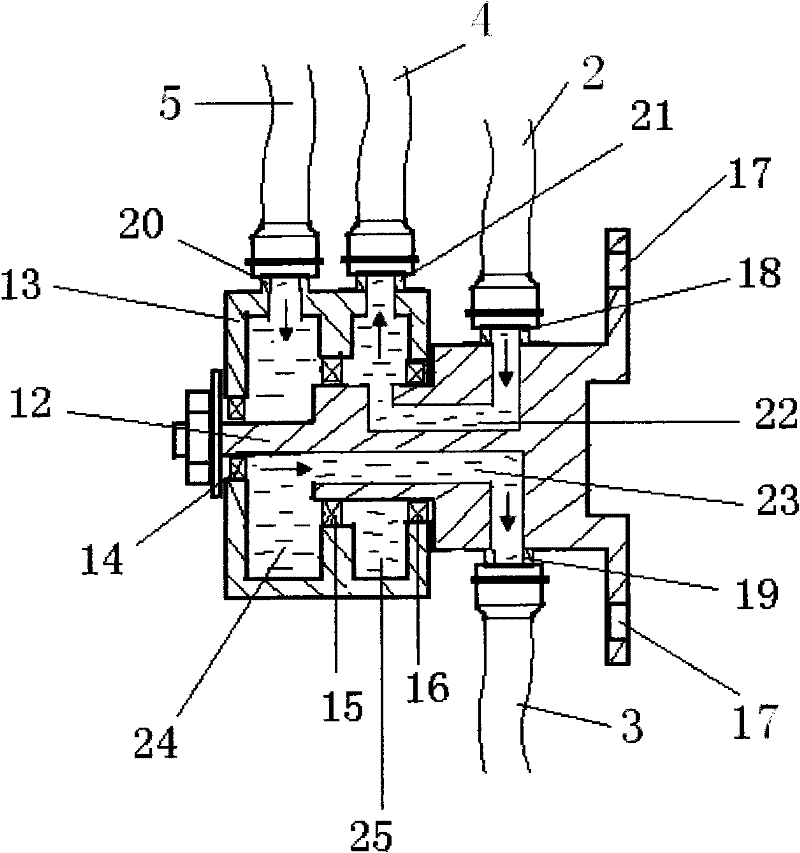

[0039] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0040] The best basic embodiment of the invention:

[0041] Please refer to the accompanying drawings, in the embodiment, the rotary water inlet and outlet device (1) consists of a static chamber (13) that is sleeved on a cylinder or a stepped cylinder rotating shaft (12), and the static chamber (13) is for setting There are double circular water jackets with water inlet and outlet pipe joints (20), (21), and the rotating shaft (12) is a cylinder provided with water inlet and outlet channels (22), (23) and water inlet and outlet joints (18), (19) Or a stepped cylinder, and three O-shaped water seal rings (14), (15), (16) are arranged between the two rotating sliding surfaces, so that the water in and out are isolated from each other and the water does not leak out. Using the rotating shaft ( 12) The screw hole (17) that one end is provided with, put the screw thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com