Buckle cap culture tube

A technology of culture tube and buckle cover, which is applied in the field of medical devices, can solve the problems of high tube height, waste of raw materials, increase of product volume, etc., and achieve the effects of saving raw materials, preventing liquid leakage, and reducing product volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

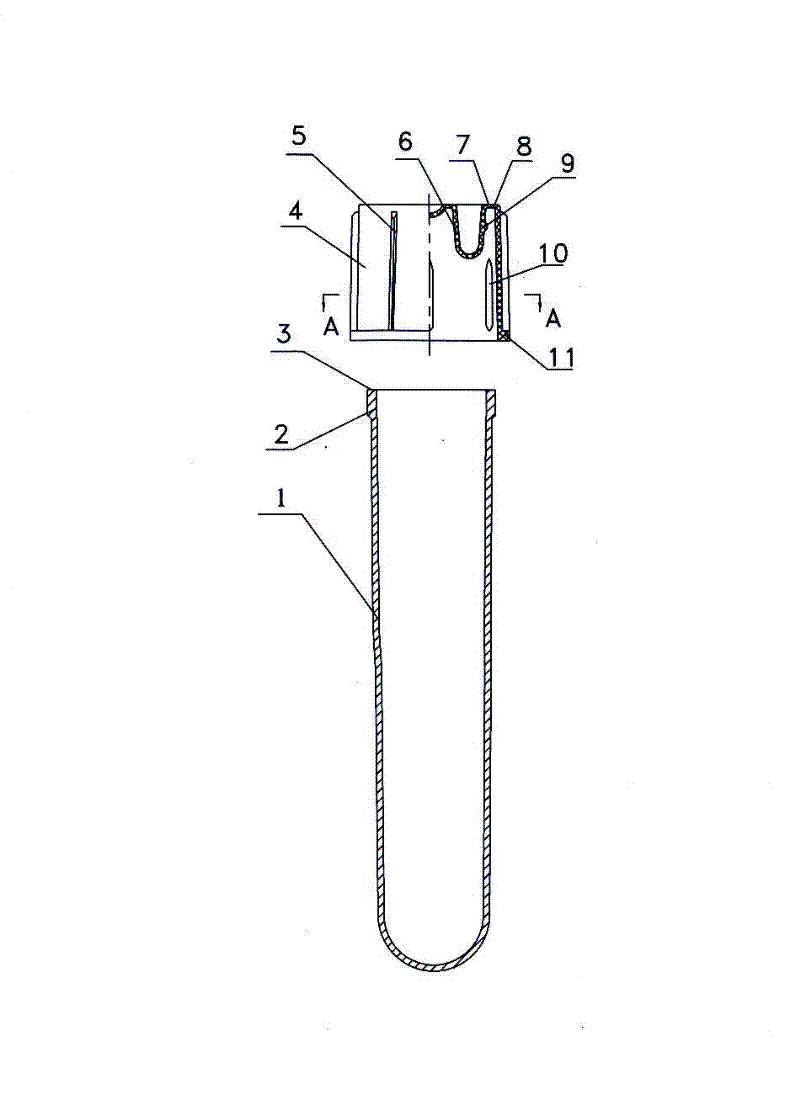

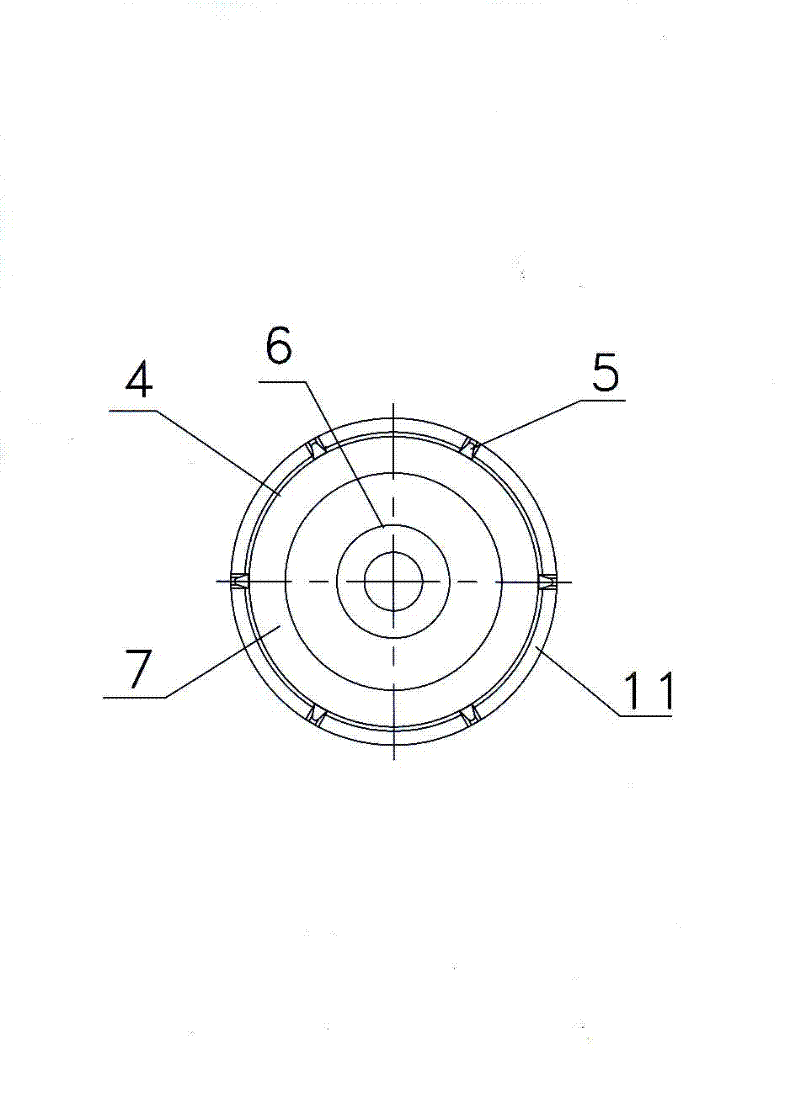

[0017] A buckle-cap type culture tube, consisting of a tube body 1 and a tube cover 4, a tube body annular protrusion 2 is processed on the top outer wall of the tube body 1, and a concave inner plug 6 is provided in the middle of the top of the tube cover, The outer wall of the inner plug 6 with a "W"-shaped cross section is smooth and can closely match the inner wall of the tube body 1, and the upper end of the outer wall of the inner plug 6 is processed with a tube cover annular protrusion 9 that can squeeze the inner wall of the tube body 1. The bottom of the ring edge 7 at the top of the tube cover 4 is provided with a tube cover ring edge bottom 8 matching the top surface 3 of the tube body 1 .

[0018] Both the top surface 3 of the tube body 1 and the bottom surface 8 of the annular edge of the tube cover are planes.

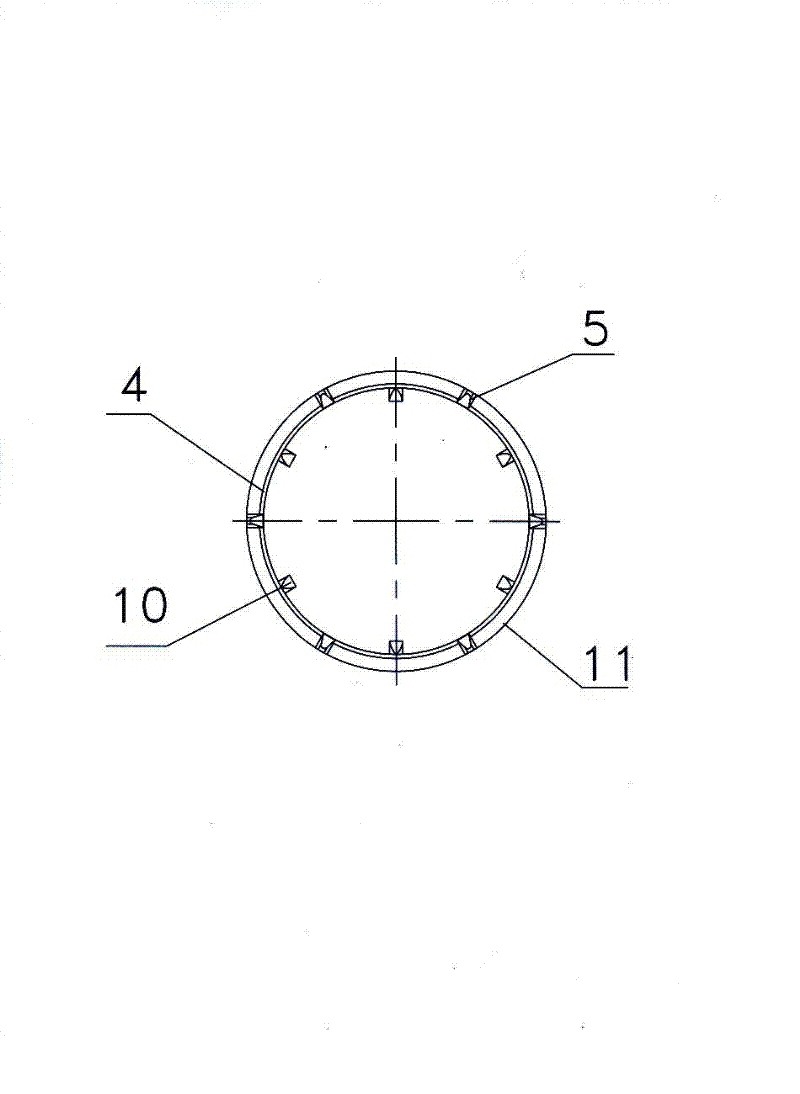

[0019] The inner wall of the pipe cover 4 is processed with several inner vertical reinforcing ribs 10 arranged at even intervals.

[0020] The outer wa...

Embodiment 2

[0023] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference is:

[0024] The top surface 3 of the tube body 1 is a convex semicircle, and the bottom surface 8 of the ring edge of the tube cover is a concave semicircle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com